- Gabatarwa

Mota mai tashi jirgin sama ce ta sirri ko kuma jirgi mai cirewa wanda ke ba da jigilar gida zuwa ƙofa a ƙasa da iska.

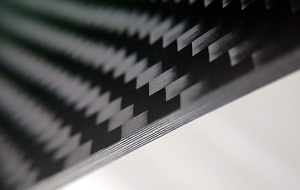

Carbon fiberza a iya amfani dashi azaman madadin abu don rage nauyi.

-Rubutu

Cunkoson ababen hawa babbar matsala ce a yau a manyan biranen kasar nan, kuma sau da yawa muna iya ganin manyan hanyoyin mota ko kuma motocin titi suna ta rarrafe a hankali kamar tururuwa a lokacin hutu. Ta yaya za mu magance wannan matsalar?

Wasu mutane na iya yin mamakin dalilin da ya sa ba za mu iya amfani da jiragen sama masu arha a matsayin abin hawa ba. Amma ra'ayin cewa farashin kera kayan jirgi da man fetur suna da tsada a zahiri ba gaskiya ba ne, sannan wani zai ce, shin za mu iya haɓaka motocin iska a matsayin sabuwar hanyar sufuri? A ce ko da za mu iya kera irin wannan motar ta iska, za mu gamu da matsaloli masu wuyar gaske, kamar rage nauyi, gina cibiyoyin zirga-zirgar jiragen sama, sarrafa sharar iska da gurbatar man fetur, keɓe hayaniya ta iska, kafa dokoki, da dai sauransu.

A cikin labarin, mun mayar da hankali kan rage nauyin jiki na iska, me yasa jigilar iska don rage nauyi? Hakan ya faru ne saboda girman nauyin mota ko jirgin da ke tuƙi a sararin sama, ƙarfin kuzari da kuma man fetur zai iya taimaka musu su ci gaba da tashi, wato, rashin ƙarfi. kuma karancin makamashi matsala ce ta duniya, don haka ya kamata mu mai da hankali kan mafita, hanya mafi kyau ita ce rage nauyin jiki. Kamar yadda muka sani, carbon fiber abu ne mai kyau mai rage nauyi, ƙarfin kuma yana da yawa. Yana da alama cewa yin amfani da fiber carbon a matsayin kayan aiki na jiki da na mota abu ne mai kyau, amma sau da yawa sababbin samfurori sukan fuskanci matsaloli da yawa kafin su fito. Misali, tsarin samar da fiber carbon yana da matukar wahala. Tsarin cin lokaci ya haɗa da ɗorawa carbon fiberboard na resin a cikin mold, warkar da tanda na tsawon sa'o'i kafin a yanke shi, sa'an nan kuma haɗa abubuwan da aka gyara tare, ta yin amfani da na'ura na CNC don aiki daidai, ta yin amfani da ƙwayar carbon fiber na musamman don tsara samfurin-siffar da sauransu.

Na biyu, farashin carbon fiber yana da yawa sosai, kafin a samar da fiber carbon, ya fara zama polymer polymer, ta carbon atom da aka haɗa da polyacrylonitrile, kuma akwai ƙwayoyin ƙwayoyin da ba na carbon ba, muna buƙatar cire su. Tilasta acrylic to fado kashe da wadanda ba carbon atoms na bukatar manyan inji da kuma mai yawa zafi, ciki har da biyu main aiki matakai: hadawan abu da iskar shaka stabilization da carbonization, wadannan matakai na bukatar wata babbar adadin high zafin jiki makamashi da kuma lokaci, da kuma masana'antun dole ne jefar da shaye gas a lokacin dumama tsari don kada ya gurɓata yanayi, wanda shi ne kawai don yin guda fiber kanta. Kuma tare da carbon fiber a matsayin madadin kayan, duk muna bukatar mu yi amfani da carbon fiber tube haši,carbon fiber laminate zanen gadoda cnc yanke carbon fiber don sake tsara wasu sassa, wanda zai iya shafar aiki da sauran dalilai.

Don haka matakin saka hannun jari na hada-hadar fiber carbon da ake samarwa da yawa don kera motocin iska zai yi yawa a halin yanzu.

www.xccarbon.com

Lokacin aikawa: Fabrairu-28-2019