I-Carbon fiber, eyakhiwe ngezinhlanganisela zezinto ezingafani (i-fiber ne-resin), ukuhlukahluka kwazo, kanjalo, ukuhleleka, isilinganiso esiyisikwele esimaphakathi nenhlese yazo. Njengengxenye yensimbi, izinhlanganisela ze-carbon fibre zinikeza amandla aphindwe kashumi kumandla ensimbi. Abakhiqizi be-carbon fibre bakha umkhiqizo onesilinganiso esiyisikwele esifanayo kodwa esingafani. I-Carbon fiber iyahlukahluka nge-tensile modulus (noma ukuqina okunqunywa njengokuwohloka ngaphansi kobunzima) kanye nokushuba, ukucindezelwa namandla okukhathala

I-PAN-based carbon fiber itholakala kulezi zinsuku nge-modulus ephansi (ngaphansi kwezigidi ezingamashumi amathathu nambili ze-lbf/in² noma i-Msi), i-modulus yesiko (33 kuya ku-Msi amashumi amathathu nesithupha), i-modulus ephakathi (40 kuya ku-Msi yamashumi amahlanu), i-modulus ephezulu (i-Msi engu-50 ukuya kwamashumi ayisikhombisa) kanye ne-ultrahigh modulus eyikhulu (ama-Msi angu-70 ukuya kweyinye).

Ngamagama alula, i-carbon fibre idalwe ngokushintshwa kwe-associate degree organic precursor fiber ku-associate degree inert atmosphere emazingeni okushisa angaphezu kuka-1800°F (982.22 °C). Ukwakhiwa kwe-carbon fibre, nokho, kungase kube ibhizinisi elithuthukile.

I-Polymerization kanye Nokuphotha

I-Polymerization

Inqubo iqala nge-chemical compound feed stock ebizwa ngokuthi i-precursor enomgogodla wamangqamuzana we-fiber. Namuhla, cishe amaphesenti angu-100 e-carbon fibre edaliwe yenziwa ngendwangu noma i-pitch-based precursors, kodwa iningi layo livela ku-polyacrylonitrile (PAN), ekhiqizwa nge-nitrite, ne-nitrite ivela kumakhemikhali ezimbonini i-propane ne-ammonia.

I-Oxidation kanye ne-Carbonization

I-oxidation

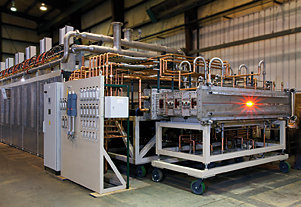

Lezi zilinganiso eziyisikwele zama-bobbins zilayishwa kubhasikidi, futhi ngaphakathi kokukhiqizwa okude kakhulu, isigaba se-oxidization, i-PAN fibers isikwele isilinganiso esinikezwa ngochungechunge lwezithando zomlilo ezizinikele. Ngaphambi kokuthi bangene entweni yokuqala yasekhishini, i-PAN fibers square measure placate ibe ithowuzi noma ishidi elibizwa ngokuthi i-warp. Izinga lokushisa legumbi lisukela ku-392 °F (ca. 200 °C) kuya ku-572 °F (300 degrees Celsius).

Ukwelashwa kwendawo kanye nokulinganisa

Ukwelashwa kwendawo kanye nokulinganisa

Isinyathelo esilandelayo sibalulekile ekusebenzeni kwefayibha, futhi ngaphezu kwalokho kozandulela, siwuhlukanisa kangcono umkhiqizo womphakeli oyedwa kumkhiqizo wezimbangi. Ukunamathela phakathi kwe-matrix organic compound ngakho-ke imicu ye-carbon ibalulekile ekuqiniseni inhlanganisela; kuyo yonke indlela yokukhiqiza i-carbon fibre, ukwelashwa kwendawo kuyenziwa ukuze kukhuliswe lokhu kunamathela.

Isikhathi sokuthumela: Nov-01-2018