Cov pa roj carbon fiber, tsim los ntawm combos tsis zoo li cov ntaub ntawv (fiber thiab resin), lawv cov variability, thiab yog li, tailorability, square ntsuas central rau lawv ntxim nyiam. Raws li kev hloov hlau, carbon fiber composites muab kaum lub zog ntawm cov hlau. Cov neeg tsim khoom siv carbon fiber ntau tsim cov khoom uas square ntsuas zoo sib xws tab sis tsis zoo ib yam. Cov pa roj carbon fiber sib txawv hauv tensile modulus (los yog khov kho raws li deformation hauv qab strain) thiab tensile, compression thiab qaug zog.

PAN-raws li carbon fiber ntau niaj hnub no nyob rau hauv qis modulus (tsawg dua peb caug-ob lab lbf / in² los yog Msi), kev cai modulus (33 mus rau peb caug-rau Msi), intermediate modulus (40 mus rau tsib caug Msi), siab modulus (50 mus rau xya caum Msi) thiab ultrahigh modulus (70 Msi rau ib puas).

Hauv cov ntsiab lus yooj yim tshaj plaws, carbon fiber yog tsim los ntawm kev hloov pauv ntawm associate degree organic precursor fiber nyob rau hauv associate degree inert cua ntawm qhov kub siab tshaj 1800 ° F (982.22 ° C). Carbon fiber ntau, txawm li cas los xij, tej zaum yuav yog kev lag luam siab heev.

Polymerization thiab Spinning

Polymerization

Cov txheej txheem pib nrog cov tshuaj lom neeg cov khoom noj khoom haus hu ua precursor uas muaj cov pob txha molecular ntawm cov fiber. Niaj hnub no, hais txog 100 feem pua ntawm cov pa roj carbon fiber ntau tsim yog tsim los ntawm cov ntaub los yog pitch-raws li precursors, tab sis feem ntau ntawm nws yog los ntawm polyacrylonitrile (PAN), tsim los ntawm nitrite, thiab nitrite los ntawm industrial chemicals propane thiab ammonia.

Oxidation Thiab Carbonization

Oxidation

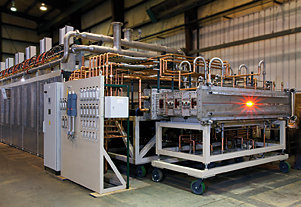

Cov bobbins square ntsuas loaded rau hauv lub pob tawb, thiab nyob rau hauv ntev tshaj plaws ntau lawm, oxidization theem, PAN fibers square ntsuas pub los ntawm ib tug series ntawm siab rauv taws. Ua ntej lawv nkag mus rau hauv cov khoom siv hauv chav ua noj, PAN fibers square ntsuas placate rau hauv ib tug cab los yog daim ntawv hu ua warp. Lub chamber kub ntawm 392 ° F (ca. 200 ° C) txog 572 ° F (300 ° C).

Kev kho deg thiab qhov loj me

Kev kho deg thiab qhov loj me

Cov kauj ruam tom ntej yog qhov tseem ceeb rau kev ua haujlwm fiber ntau, thiab ntxiv rau cov khoom ua ntej, nws zoo tshaj qhov txawv ntawm ib tus neeg muag khoom cov khoom los ntawm cov khoom sib tw. Lub adhesion ntawm matrix organic compound thiab yog li cov pa roj carbon fibers yog qhov tseem ceeb rau kev txhawb nqa cov khoom sib xyaw; thoob plaws hauv txoj kev tsim cov pa roj carbon fiber ntau, kev kho saum npoo yog ua los txhawb qhov adhesion.

Post lub sij hawm: Nov-01-2018