Fiber Carbon, wanda ya ƙunshi combos na kayan da ba kamar fiber ba (fiber da resin), bambancinsu, don haka, daidaitawa, ma'aunin murabba'in tsakiyar fara'a. A matsayin maye gurbin ƙarfe, abubuwan haɗin fiber carbon suna ba da ƙarfin ƙarfe sau goma. Masu kera fiber na carbon suna ƙirƙirar samfur wanda ma'aunin murabba'in iri ɗaya ne amma ba iri ɗaya ba. Fiber Carbon ya bambanta a cikin modulus na tensile (ko ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙasƙanci a ƙasa) da ƙarfi, matsawa da ƙarfin gajiya.

Ana samun fiber carbon fiber na tushen PAN kwanakin nan a cikin ƙananan modulus (kasa da miliyan talatin da biyu lbf/in² ko Msi), modulus na al'ada (33 zuwa talatin da shida Msi), matsakaicin modules (40 zuwa Msi hamsin), babban modulus (50 zuwa Msi saba'in) da ultrahigh (70 zuwa ɗari da arba'in Msi).

A cikin mafi sauƙi, fiber carbon an ƙirƙira shi ta hanyar matsawa matakin haɗin gwal na ƙirar fiber na haɗin gwiwa a cikin yanayin ƙarancin ƙarancin digiri a yanayin zafi sama da 1800 ° F (982.22 ° C). Kera fiber carbon, duk da haka, na iya zama ci-gaban sana'a.

Polymerization da Kadi

Polymerization

Tsarin yana farawa ne da kayan abinci na fili na sinadari da ake magana da shi azaman mafari wanda ke da kashin bayan kwayoyin fiber. A yau, game da kashi 100 na fiber carbon da aka ƙirƙira an ƙirƙira shi ne da zane ko abubuwan da aka samo asali, duk da haka yawancinsa ya fito ne daga polyacrylonitrile (PAN), wanda aka kera daga nitrite, kuma nitrite ya fito ne daga sinadarai na masana'antu propane da ammonia.

Oxidation da Carbonization

Oxidation

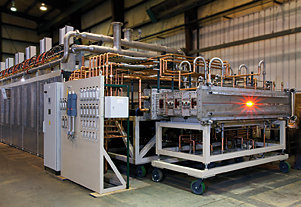

Wadannan ma'aunin murabba'in bobbins an ɗora su a cikin kwandon, kuma a cikin mafi tsayin samarwa, matakin oxidization, ma'aunin murabba'in PAN fibers wanda aka ciyar da shi ta jerin tanderun da aka keɓe. Kafin su shiga kayan aikin dafa abinci na farko, ma'aunin filaye na PAN suna sanya a cikin ja ko takarda da ake magana da shi azaman warp. Yanayin zafin ɗakin yana daga 392 °F (kimanin 200 ° C) zuwa 572 °F (digiri 300 Celsius).

Maganin saman da girman

Maganin saman da girman

Mataki na gaba yana da mahimmanci ga aikin fiber, kuma ga abubuwan da aka riga aka ambata, ya fi bambanta samfurin mai kaya ɗaya daga samfuran masu fafatawa. Adhesion tsakanin matrix Organic fili kuma sabili da haka carbon fibers suna da mahimmanci don ƙarfafa haɗin gwiwar; a ko'ina cikin hanyar samar da fiber carbon, ana yin jiyya a saman don haɓaka wannan mannewa.

Lokacin aikawa: Nov-01-2018