Fiber ea carbon, e entsoeng ka li-combos tse sa rateheng (fiber le resin), ho fetoha ha tsona, 'me kahoo, ho khoneha, lisekoere tse bohareng ba botle ba tsona. E le sebaka sa tšepe, metsoako ea carbon faeba e fana ka matla a tšepe ka makhetlo a leshome. Bahlahisi ba fiber ea carbon ba etsa sehlahisoa se nang le lisekoere tse lekanang empa li sa tšoane. Carbon fiber e fapana ka modulus e tsitsitseng (kapa ho satalla ho khethoa e le deformation ka tlase ho khatello) le ho tsieleha, khatello le matla a mokhathala.

PAN-based carbon fiber e fumaneha matsatsing ana ka modulus e tlase (tlase ho limilione tse mashome a mararo a metso e 'meli lbf/in² kapa Msi), modulus ea setso (33 ho isa ho mashome a mararo a metso e tšeletseng Msi), modulus ea mahareng (40 ho isa ho mashome a mahlano Msi), modulus e phahameng (Msi 50 ho isa ho mashome a supileng) le ultrahigh modulus bakeng sa lekholo la Msi tse mashome a supileng ho isa ho a le mong).

Ka mantsoe a bonolo, faeba ea khabone e hlahisoa ke phetoho ea degree ea organic precursor fiber ka har'a sepakapaka sa "inert" sa "associate degree" mocheso o fetang 1800 ° F (982.22 ° C). Leha ho le joalo, tlhahiso ea fiber ea carbon e ka ba khoebo e tsoetseng pele.

Polymerization le ho ohla

Polymerization

Ts'ebetso e qala ka phepelo ea motsoako oa lik'hemik'hale e bitsoang selelekela se nang le mokokotlo oa limolek'hule oa fiber. Kajeno, hoo e ka bang karolo ea 100 lekholong ea carbon fiber e entsoeng e entsoe ka lesela kapa li-precursors tse thehiloeng ho sekontiri, leha ho le joalo boholo ba tsona bo tsoa ho polyacrylonitrile (PAN), e entsoeng ka nitrite, le nitrite e tsoa ho lik'hemik'hale tsa indasteri tsa propane le ammonia.

Oxidation le Carbonization

Oxidation

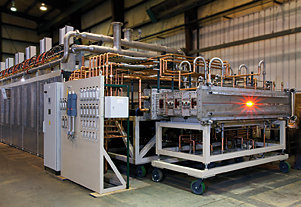

Li-bobbins square measurement tsena li kentsoe ka basketeng, 'me nakong ea tlhahiso e telele ka ho fetisisa, sethaleng sa oxidization, PAN fibers square measure e fepeloa ka letoto la libopi tse inehetseng. Pele ba kena ka kichineng ea mantlha, li-fibers tsa PAN li etsa lisekoere tsa lisekoere ka har'a tow kapa lakane e bitsoang warp. Mocheso oa kamore o tloha ho 392 °F (hoo e ka bang 200 °C) ho ea ho 572 °F (300 degrees Celsius).

Phekolo ea bokaholimo le boholo

Phekolo ea bokaholimo le boholo

Mohato o latelang ke oa bohlokoa bakeng sa ts'ebetso ea fiber, 'me ho phaella ho li-precursors, e khetholla hantle sehlahisoa sa morekisi a le mong ho sehlahisoa sa bahlolisani. Ho khomarela pakeng tsa motsoako oa motsoako oa matrix 'me kahoo likhoele tsa carbon li bohlokoa bakeng sa ho matlafatsa motsoako; ho pholletsa le mokhoa oa ho hlahisa carbon fiber, phekolo ea holim'a metsi e etsoa ho matlafatsa sekhomaretsi sena.

Nako ea poso: Nov-01-2018