Ifayibha yeCarbon, eyenziwe ngee-combos ezingafaniyo nemathiriyeli (ifayibha kunye ne-resin), ukuguquguquka kwazo, kwaye ke, ukulungelelaniswa, umlinganiselo wesikweri osembindini womtsalane wabo. Njengokutshintshwa kwesinyithi, i-carbon fiber composites inikezela ngokuphindwe kalishumi amandla entsimbi. Abavelisi beCarbon fiber benza imveliso enomlinganiselo osisikweri ofanayo kodwa awufani. Ifayibha yeCarbon iyahluka kwimodyuli yokuqina (okanye ukuqina okugqitywe njengotshintsho olungaphantsi koxinzelelo) kunye nokuqina, uxinzelelo kunye namandla okudinwa.

I-PAN-based carbon fiber ifumaneka kule mihla kwimodyuli ephantsi (ngaphantsi kwezigidi ezingamashumi amathathu anesibini ze-lbf/in² okanye i-Msi), imodyuli yesiko (33 ukuya kumashumi amathathu anesithandathu uMsi), imodyuli ephakathi (40 ukuya kumashumi amahlanu Msi), imodyuli ephezulu (50 ukuya kumashumi asixhenxe eMsi) kunye nemodyuli ye-ultrahigh ngekhulu (70 ukuya kwikhulu leMsi).

Ngamagama alula, ifayibha yekhabhoni yenziwa ngokutshintsha kwe-associate degree organic precursor fiber kwi-associate degree inert atmosphere kumaqondo obushushu angaphezu kwe-1800°F (982.22 °C). Ukwenziwa kweCarbon fiber, nangona kunjalo, inokuba lishishini eliphambili.

I-Polymerization kunye nokuSpin

Ipolymerization

Inkqubo iqala ngesitokhwe sokutya sekhemikhali esibizwa ngokuba yi-precursor ene-molecular backbone yefiber. Namhlanje, malunga ne-100 yepesenti ye-carbon fiber eyenziwe ngelaphu okanye i-pitch-based precursors, nangona kunjalo uninzi lwayo luvela kwi-polyacrylonitrile (PAN), eyenziwa kwi-nitrite, kunye ne-nitrite ivela kwiikhemikhali zepropane kunye ne-ammonia.

I-Oxidation kunye neCarbonization

I-oxidation

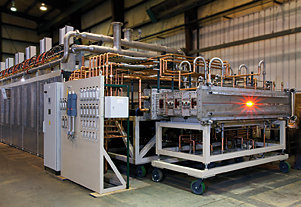

Le bobbins square measurement ilayishwe kwibhaskithi, kwaye ngaphakathi kwemveliso inde, inqanaba le-oxidization, i-PAN fibers imilinganiselo yesikwere esondliwa ngothotho lweziko ezinikezelweyo. Phambi kokuba bangene kwisixhobo sokuqala sasekhitshini, iintsinga zePAN zokulinganisa isikwere zibe yintambo okanye ishiti elibizwa ngokuba yi-warp. Ubushushu begumbi busukela kwi-392 °F (ca. 200 °C) ukuya kuma-572 °F (300 degrees Celsius).

Unyango lomphezulu kunye nokulinganisa

Unyango lomphezulu kunye nokulinganisa

Inyathelo elilandelayo libalulekile ekusebenzeni kwefayibha, kwaye ukongeza kwizandulela, iyohlula ngcono imveliso yomthengisi omnye kwimveliso yokhuphiswano. Ukubambelela phakathi kwe-matrix organic compound kwaye ngoko ke iifiber zekhabhoni ziyimfuneko ekuqiniseni i-composite; kuyo yonke indlela yokuvelisa i-carbon fiber, unyango lomphezulu lwenziwa ukunyusa oku kubambelela.

Ixesha lokuposa: Nov-01-2018