1 Isingeniso

I-Carbon fiber reinforced epoxy composite (CFRP) inezinzuzo eziningi ezifana nokuminyana okuphansi, amandla athile aphezulu, ukuqina okuqondile okuphezulu, ukumelana nokukhathala, ukumelana nokugqwala kanye nezakhiwo ezinhle zokukhanda. Isetshenziswa kabanzi ku-aerospace nakwezinye izakhiwo ezinokhahlo ngokwezemvelo, ukushisa okumanzi kanye nomthelela. Umthelela wezici zemvelo ezintweni ezibonakalayo uya ngokuya ubonakala. Eminyakeni yamuva nje, izazi zasekhaya nezangaphandle zenze izifundo eziningi ngemiphumela yendawo eshisayo nenomswakama ezinhlanganisela ze-CFRP [1] kanye nomthelela womthelela kuzinhlanganisela ze-CFRP. Ucwaningo luthole ukuthi ithonya lendawo eshisayo nenomswakama ezinhlanganisela ze-CFRP ihlanganisa ukwenziwa kwepulasitiki kwe-matrix [2, ukuqhekeka [31 kanye nezakhiwo ezibuthakathaka ze-fiber-matrix ezibukwayo [2'3'5], ukugoba okuyinhlanganisela ye-CFRP nokwenyuka kwesikhathi sokwelashwa kokushisa okumanzi) Izici zomshini zokusebenza [2, umthofu kanye ne-interlaminar shear properties [2, 13 kanye ne-6'7] izakhiwo ezinyakazayo. Woldesenbet et al. [8,9] ufunde umthelela wezakhiwo zemishini yezinhlanganisela emazingeni aphezulu obunzima ngemva kokwelashwa kokushisa okumanzi, futhi wathola ukuthi indawo eshisayo neyomswakama yathuthukisa amandla omthelela wezinhlanganisela. Kuvezwa ukuthi ukumuncwa komswakamo wezinto eziyinhlanganisela kungathuthukisa izici zomshini womthelela wezinto ezisetshenziswayo ngaphansi kwezimo ezithile, okwehluke kakhulu emiphumeleni yokuhlola ngaphansi kwezimo ze-quasi-static. Umsebenzi wamanje omkhulu wocwaningo umphumela wokushisa okumanzi (okuhlanganisa nokucwiliswa kwamanzi) ezicini zomthelela wesivinini esiphansi sezinhlanganisela ze-fiber resin resin matrix. U-Pan Wenge et al [10] bafunde izici zokucindezelwa kwe-fiberglass/epoxy composite composite laminates enezinhlangothi ezimbili ngemva komthelela wesivinini esiphansi ekamelweni lokushisa nangaphansi kwezimo ezishisayo nezinomswakama (65 °C ukucwiliswa emanzini). 4. I-laminate ngaphansi kwendawo eshisayo neyomswakama itholakala ngemva kokushaqeka kwejubane eliphansi. Ukusebenza kokucindezela kuncishiswe kakhulu. Karasek et al. [1] ufunde imiphumela yomswakama kanye nezinga lokushisa kumthelela wezinhlanganisela zegraphite/epoxy, futhi wazithola endaweni yokushisa ephansi nasezindaweni zokushisa zegumbi. Ukuswakama kunomphumela omncane emandleni okuqala kanye nokumuncwa kwamandla komonakalo. U-Yucheng zhong et al [12,13] wenze ukuhlolwa komthelela wesivinini esiphansi kuma-laminate ahlanganisiwe ngemva kokwelashwa kokushisa okumanzi. Kuphetha ngokuthi indawo eshisayo neyomswakama inciphisa kakhulu umonakalo womthelela we-laminate. Thuthukisa ukumelana komthelela wama-laminates. UKrystyna et al. [14] itadishe umthelela wesivinini esiphansi se-aramid-glass fiber/epoxy composite ngemva kokwelashwa kokushisa okumanzi (70 °C ukucwiliswa emanzini), futhi yathola indawo yokulimala komthelela omncane ngemva kokwelashwa kokushisa okumanzi. Lokhu kubangela ukulimala kwe-delamination ngaphakathi kwesampula, edonsa amandla engeziwe ngesikhathi somthelela futhi ivimbele ukwakheka kwe-delamination. Kungabonakala kulokhu okungenhla ukuthi umthelela wendawo yokushisa okumanzi emonakalweni womthelela wezinto eziyinhlanganisela unomphumela okhuthazayo kanye nomphumela obuthakathaka. Ngakho-ke, ucwaningo olwengeziwe nokuqinisekisa kuyadingeka. Ngokomthelela, u-Mei Zhiyuan et al [15] uhlongoze futhi wasungula izigaba ezimbili (ukungena kwe-shear kanye nokungena okuqhubekayo) imodeli yokuhlaziya amandla e-dynamics yama-laminate ahlanganisiwe aqiniswe nge-fiber ngaphansi komthelela wesivinini esikhulu. Guiping Zhao et al. [16] yenze izinhlobo ezintathu zezivinini ezihlukene (ezingaphansi, ezilingana nezinkulu kunejubane lomkhawulo we-ballistic) ekusebenzeni komthelela kanye nokulimala kwesifanekiso ngemva kwezinhlobo ezintathu zamalayini, kodwa ayizange ifake umthelela wendawo yokushisa okumanzi emonakalweni womthelela. . Ngokusekelwe ezincwadini ezingenhla, ucwaningo oluhlobene nomthelela wemvelo emanzi neshisayo kuma-fiber reinforced composite laminates kusazoqhutshekwa nokuhlolwa. Kuleli phepha, izici zokulimala komthelela wokushisa okumanzi okugcwele i-carbon fibre/epoxy composite laminates ngaphansi kwezimo zokugeza zamanzi ezingu-70 °C zafundwa. Imiphumela yendawo eshisayo neswakeme ezicini zokuhluleka komthelela zezinhlanganisela zahlaziywa ngokuqhathanisa namasampuli okushisa egumbi elomile. Ocwaningweni, amalayithi e-CFRP athikamezekile ku-CFRP laminates ku-45 m/s, 68 m/s kanye no-86 m/s. Isivinini ngaphambi nangemuva komthelela sikaliwe. Ithonya lendawo eshisayo neyomswakama ekusebenzeni kokumuncwa kwamandla kwama-laminates kwahlaziywa. I-ultrasonic c-scan yasetshenziswa ukuze kutholwe umonakalo wangaphakathi we-laminate, futhi nomthelela wesivinini somthelela endaweni ephukile yahlaziywa. Imakroskopu ye-electron yokuskena kanye nesistimu ye-ultra-depth-deep ye-microscopic enezinhlangothi ezintathu zisetshenzisiwe ukuze kubonwe izici ze-mesoscopic zomonakalo wesampula, futhi umonakalo wesampula wahlaziywa indawo yokushisa eswakeme. Umthelela wezici.

2 Izinto zokuhlola nezindlela

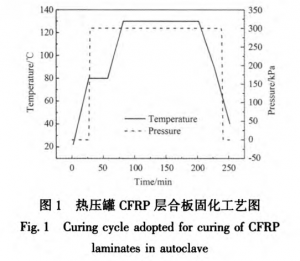

2. 1 Impahla nokulungiselela

I-Carbon fiber epoxy resin (T300/EMl 12) impahla eyinhlanganisela, ukucwiliswa kwangaphambili okuhlinzekwa yi-Jiangsu Hengshen Co., Ltd., ugqinsi lwesendlalelo esisodwa sangaphambi kokucwiliswa okungu-0. 137 mm nengxenye yevolumu yefiber engu-66%. Iphaneli ye-laminate ibekwe phansi kwesendlalelo. , usayizi 115mm x 115mln. Kusetshenziswa inqubo yokwenza ithangi lokucindezela okushisayo. Umdwebo wenqubo yokuphulukisa olungiselelwe inqubo uboniswa kuMfanekiso 1. Okokuqala phakamisa indawo yokuhlala kusuka ekamelweni lokushisa kuya ku-80 oC ngesilinganiso sokushisa kwe-1 kuya ku-3 oC / min, bese ufudumala imizuzu engu-30, ukushisa kuya ku-130 oC ngezinga lokushisa lika-l13 oC / min, gcina ukushisa ku-120 min, wehlise ku-60.0C ngesilinganiso sokupholisa esiqhubekayo, bese ususa ukucindezela nokukhulula, futhi ukhulule.

2. 2 Ukwelashwa kokushisa okumanzi

Ngemuva kokulungiswa kwesifanekiso, isampula liphathwe ngokushisa okumanzi ngokuhambisana nencazelo HB 7401-96.171 "Indlela yokuhlola yokumunca umswakama osuselwa ku-resin-based resin-hot hot absorption". Okokuqala, i-specimen ifakwa ekamelweni lokumisa le-thermostatic ku-70 degrees C ukuze lome. Ukukala njalo usebenzisa izilinganiso kuze kube yilapho ukulahlekelwa kwekhwalithi yesampula kuzinzile kungabi ngaphezu kuka-0. 02%, inani elirekhodiwe ngalesi sikhathi liyi-Engineering Dry Mass G. Ngemva kokumiswa, isifanekiso sifakwa ku-70 degrees C wamanzi ukuze kuphathwe ukushisa okumanzi. Ngokuvumelana nencazelo HB 7401. Indlela ecaciswe ku-96 "ikala ikhwalithi yesifanekiso nsuku zonke, erekhodwa njenge-Gi, futhi irekhoda ukuguqulwa kokumuncwa komswakama Mi. Inkulumo yokumunca umswakama wesampula ye-CFRP laminate ithi:

Ifomula inemininingwane eminingi: I-Mi ukumuncwa komswakamo kwesifanekiso, i-Gi iyikhwalithi ngemva kokuba isampula limunca umswakama, g, i-go ikhwalithi yesimo esomile sobunjiniyela besampula.

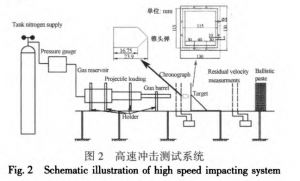

2. 3 Izivivinyo Zomthelela

Ukuhlolwa komthelela wesivinini esikhulu ku-CFRP laminate kwenziwa ngenganono yomoya enesivinini esikhulu enobubanzi obungu-15 mm. Idivayisi yokuhlola umthelela wesivinini esikhulu (bona Umfanekiso 2) ihlanganisa isibhamu somoya esinesivinini esikhulu, idivayisi yokulinganisa isivinini nge-laser ngaphambi nangemuva komthelela, umzimba wenhlamvu, isifanekiso sokufakwa kwesifanekiso (ikhona eliphezulu kwesokudla soMfanekiso 2), kanye nedivayisi yokutakula ukuphepha komzimba wenhlamvu. Umzimba wenhlamvu iyinhlamvu ye-cylindrical enekhanda lekhoni (Umfanekiso 2), futhi umthamo wenhlamvu ungama-24. 32 g nobubanzi obungu-14. 32 mm; isivinini somthelela ngu-45 m/s (amandla omthelela 46 J), 68 m/s (amandla omthelela 70 J), 86 m/s (amandla omthelela 90 J) umthelela.

2. 4 Ukutholwa komonakalo wezibonelo

Ngemva kokuthintwa umthelela, ipuleti le-carbon fibre color epoxy composite composite laminate layer edgout plate lisetshenziselwa ukubona umonakalo wangaphakathi womthelela wepuleti le-laminate ye-CFRP, futhi indawo yokuqagela yendawo yomonakalo womthelela ikalwa ngesofthiwe yokuhlaziya isithombe i-UTwim, kanye nezici ezinemininingwane zokucekelwa phansi kwezigaba ezihlukene zibonwa ngokuskena isibonakhulu se-electron kanye ne-ultra-3D yesistimu ye-ultra-deep.

3 Imiphumela nezingxoxo

3. 1 Ibonisa izici zokumunca umswakama

Isamba esingu-37. 7 d, isilinganiso sokumuncwa komswakama ogcwele singu-1. 780%, nesilinganiso sokusabalalisa esingu-6. 183x10. 7llnl2/s. Ijika lokumunca umswakama lesampula le-CFRP laminate liboniswa kuMdwebo 3. Njengoba kungabonakala kuMfanekiso 3, izinga lokukhula lokuqala lokumuncwa komswakama wesifanekiso liqondile, ngemva kwesigaba somugqa, izinga lokukhula lokumuncwa komswakama liqala ukwehla, lifinyelele izinga lesimo esizinzile ngemva kwesikhathi esingaba ngu-23 somswakama, futhi lifinyelele isikhathi somswakama. Ngakho-ke, ukumuncwa komswakama we-specimen kuhambisana nemodi yokumunca umswakama wezigaba ezimbili: isigaba sokuqala sokumunca umswakama kungenxa yesenzo esihlangene sokushisa nomswakama, umswakama ngokusebenzisa impahla ngokwayo iqukethe ama-pores, izimbobo, imifantu kanye nezinye iziphambeko ezisakazwa ngaphakathi kwendawo; Ukusakazwa kwamanzi kuhamba kancane futhi kancane kancane kufinyelela ekugcwalisweni kulesi sigaba.

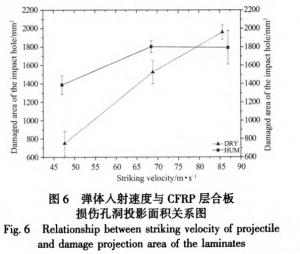

3. Izici zokubhubhisa ezibonakalayo zebhodi le-laminate ye-2-layer

Isivinini somthelela esingu-86 m/s lapho isifanekiso sangaphambili, ingemuva lemephu yephrofayela yokucekelwa phansi ebonakalayo, ngesampula lokushisa kwegumbi elomile, isifanekiso sokugcwala esimanzi esishisayo somumo wembubhiso yangaphambili kufana nokuthi, ama-specimens amabili kumthelela, ngenxa yokuqhekeka kwesisekelo, ukubhujiswa kwawo ongqimbeni lokuqala lwefayibha kunokushelela okuthile. Lokhu kubangela ukuthi ingaphambili linikeze umumo oyi-elliptical noma unxande, futhi ngaphezu kokukwazi ukubona ukuqhekeka kwe-substrate, imicu ingabonakala iphuka. Ngesampula yezinga lokushisa legumbi elomile, isampula yokugcwala okumanzi okumanzi ngemuva kokucekelwa phansi komumo kungabonakala ukuthi ingemuva elihambisana nendawo yomthelela lineqhuqhuva elithile, futhi liveza ukuqhekeka okumise okuphambene. Kusobala ukuthi i-fiber fracture, isisekelo sokuqhekeka kanye ne-interlayer fracture (i-layering) izinhlobo ezintathu zokubhujiswa, ingxenye yokugcina ye-fiber iphakanyisiwe kodwa ayiphukile, i-layer kuphela kanye ne-fiber / base cracking. I-fiber fracture nayo ihlukile, njengoba kungabonakala ekuqhathaniseni umonakalo wangaphambili nangemuva. Ingaphambili libangela ukuphuka kwe-fiber kanye ne-substrate ngenxa yokucindezelwa nokugunda. Ingemuva kungenxa yokwelula okubangele ukuthi i-fiber iphule futhi ibeke i-substrate. Umfanekiso 4 isivinini sokushaqeka esingu-45 m/s, 68 m/s, 86 m/s uma isifanekiso somonakalo wangaphakathi siskena. Indawo ekhonjiswe umugqa oyindilinga oyindilinga ompunga phakathi nendawo yesibalo iyindawo ehlongozwayo yomgodi wokulimaza. Umugqa omnyama ngenhla nangaphansi kweshadi ngalinye elincane ubonisa indawo yendawo ecwecwayo yasemuva yesampula. Indawo ephawulwe emgqeni omhlophe kumfanekiso (b) (d) (f) iwumonakalo wangaphakathi wesampula eduze komngcele. Igrafu ibonisa ukuthi amandla omthelela ayanda njengoba isivinini somthelela sikhula. Ipuleti elakhiwe nge-laminated liyakwazi ukumunca amandla engeziwe ngesikhathi somthelela (bheka uMdwebo 6 ukuze uthole amanani athile), okuholela ekwandeni kwendawo eyandayo yomonakalo we-laminate: ngokuqhathanisa isampula lokushisa kwegumbi elomile nesithombe sesampula sokugcwala okumanzi okushisayo, kungabonakala ukuthi kunomonakalo wangaphakathi (umugqa omhlophe) wesifanekiso esikhiqizwe emngceleni wokubonwa kokushisa okumanzi ngenxa yenqubo yokugcwala okumanzi okubangelwa ukugcwala kwendawo. I-plasticization ye-substrate epuleti le-laminate kanye nokuba buthakathaka kwesixhumi esibonakalayo se-fiber-base kubangela ukuthi umngcele ube nomthelela othile ku-plate laminate phakathi nenqubo yomthelela. Ngokusho kwesibalo, indawo yokucwenga emuva (umugqa omnyama) we-specimen esimweni esomile ayihlukile kakhulu esimweni sokumanzisa okushisayo.

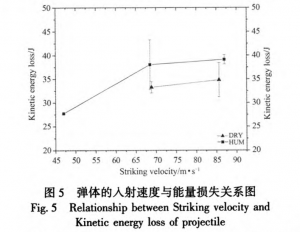

3. Izici ezinemininingwane ezonakalisayo zephaneli yezendlalelo ezi-3

Imephu yesici somonakalo wezingxenye eziphambanayo wepuleti elihlanganyelwe le-CFRP, elithathwe i-3D microsystem ejulile kakhulu nesibuko se-electron esithwebula, esinesivinini somthelela esingu-45 m/s, esomile nesimanzi futhi sishise, sibonisa ukuthi umonakalo wesifanekiso kuzo zombili izifundazwe uhlanganisa izinhlobo ezintathu zokucekela phansi: ukuphuka kwefayibha, ukuqhekeka kwesisekelo nokuphuka kwe-interlayer. Kodwa isisekelo salezi zibonelo ezimbili siqhekeke ngokuhlukile. Ukuqhekeka kwe-substrate esimweni esomile kuphukile ekuxhumaneni phakathi kwe-fiber ne-substrate. Kodwa-ke, ukuqhekeka kwe-substrate ngemva kokwelashwa kokushisa okumanzi kuhambisana nezingcezu ze-substrate eziwa. I-Wold-esenbet nezinye izinto endaweni emanzi neshisayo yokusebenza komthelela wesakhiwo sesakhiwo kanye ne-fiber substrate interface ukuwohloka okunqunywe ngokuhlanganyela, endaweni eshisayo emanzi, ipuleti lesendlalelo se-CFRP kusipiliyoni sesisekelo se-resin ukumuncwa kwenani elithile lamanzi, amanzi agelezayo azobangela i-resin substrate ukuba incibilike. I-Carbon fiber ayimunceli, khona-ke kufanele kube nokunwebeka okumanzi phakathi kokubili, lo mehluko wenza buthaka isikhombimsebenzisi phakathi kwe-substrate ne-fiber, kunciphisa amandla e-substrate. Uma ingaphansi komthwalo womthelela, izingcezwana ze-substrate zidedelwa kalula, okuholela kumehluko kusixhumanisi esibonakalayo somonakalo wesampula segumbi elomile. Kusukela esakhiweni esiningiliziwe sesibuko sikagesi esiskeniwe, kungabonakala ukuthi ukuqhekeka komzimba we-post-base omanzi futhi oshisayo ikakhulukazi ukuqhekeka okuxekethile kwekhefu lokucindezela, kuyilapho ukuqhekeka ngaphambi kokushisa okumanzi ikakhulukazi ku-brittle, futhi ukuqhekeka kwe-shear enezingqimba phakathi kwezingqimba kubonakala ngokucacile. Kusukela ku-microscope optical emfanekisweni, kungabonakala ukuthi amafomu okubhubhisa ahlukile ezimweni ezimbili, futhi isimo esomile singukubhujiswa kwe-inter-cutting. Ukusika ukubhujiswa ikakhulukazi, ngemuva kokushisa okumanzi kwefomu lokubhujiswa okuhambisana nokubhujiswa okunezingqimba ezibalulekile, ingxenye yokubhujiswa okugqinsiwe yanda. Ingabonakala nge-engeli yomshini wokubhubhisa nezici zokumunca amandla. U-Mei Zhiyuan ubeke phambili izigaba ezimbili zokuhlasela kwe-projectile: isigaba sokusika kanye nesigaba sokuhlasela esiqhubekayo. Indawo A kusampula elishisayo elimanzi ukubhujiswa kwesiteji sokugenca, ikakhulukazi ngenxa yokuthi inqubo yomthelela, ipuleti elendlayo liyacindezelwa futhi ligundwe ukwakheka kwe-deformation yokubhujiswa, indawo b ukubhujiswa okuqhubekayo kwesiteji sokuhlasela. Lesi sigaba ngokuyinhloko sibangelwa ukuncishiswa kwejubane lokungena komzimba wenhlamvu ngaphansi kwesenzo sengxenye yokucindezeleka okunwetshiwe kwesendlalelo se-fibrous, futhi amandla aguqulwa kakhulu abe amandla e-fiber stretch strain kanye namandla okuphuka kwe-interlayer (l 51), ukuze i-fiber break el kanye ne-fiber break yangaphambilini ingekho emgqeni oqondile. Kusampula esomile, lesi senzakalo asibonakali, futhi umonakalo wepuleti unzima kakhulu, ipuleti lesendlalelo linesimo sokuqhekeka. 3. 4 Ukuhlaziywa kwendawo yokukhonjiswa kwamandla okumuncwa kanye nomgodi wokulimaza Umdwebo 5 ubonisa ubudlelwano phakathi kwezinga lokushisa legumbi elomile kanye nokugcwala okumanzi okushisayo kwejubane lokuqalisa kanye nokulahlekelwa amandla emzimbeni, ngesivinini sesigameko esingaba ngu-45 m/s, izinga lokushisa elomile lenhlamvu liphindela emuva, ngakho aliboniswanga esithombeni. Njengoba kungabonwa Emfanekisweni 7, lapho ukuhlolwa kuhlolwa ngaphansi kokugcwala kokushisa okumanzi, ukulahleka kwamandla enhlamvu kubi kakhulu, namandla okumunca wesampula ngemva kokwenyuka kokwelashwa kokushisa okumanzi.

Umfanekiso wesi-6 wumdwebo wegrafu wendawo yokuqagela yesivinini sesigameko somzimba wenhlamvu kanye nembobo yomonakalo wengqimba ye-CFRP (umugqa ompunga uphawula ingxenye yoMdwebo 4), umfanekiso ophelele (4), (5), (6) ungabonakala: (1) ngokwanda kwesivinini somthelela, ungqimba lwe-CFRP lomonakalo wembobo endaweni luyakhuphuka; ukugcwala okushisayo; (3) uma isivinini somthelela sicishe sibe ngu-45 m/s, indawo ekhonjiswayo yembobo yomonakalo wepuleti eline-laminated ngemva kokwelashwa kokushisa okumanzi inkulu kakhulu kunendawo ekhonjiwe yembobo yokulimala kwepuleti elalineni endaweni yokushisa yegumbi elomile. Umonakalo wesampula wokugcwala okushisayo okumanzi indawo yokuqagela ye-l-hole inyuke ngo-85. 1% futhi ngesivinini sokushaqeka esingaba ngu-68 m/s, ipuleti elaminethiwe endaweni emanzi nokugcwala okushisayo lenyuke ngo-18. 10%, inani lokumuncwa (Umfanekiso 5) lenyuke ngo-15. 65%; Ngesivinini somthelela esingaba ngu-88 m/s, ipuleti eline-laminated endaweni emanzi ne-thermal saturation yehliswe ngo-9. 25%, inani lokumunca lisakhuphuka ngo-12. 45%.

Ngokusekelwe emiphumeleni yocwaningo ye-Yucheng Zhong neminye imikhiqizo, ukumuncwa komswakama wezinto eziyinhlanganisela eziqiniswe nge-carbon fibre kuthuthukisa umkhawulo wokunwebeka kanye nomthelela wokumelana kwepuleti le-laminate, futhi kuhlanganisa indawo ehlongozwayo yembobo yomonakalo yesampula yokushisa yegumbi elomile kanye nesampula yokugcwala okumanzi okumanzi kuleli phepha (Umdwebo 4 kumugqa wephrojekthi ompunga nomugqa ompunga wephrojekthi) Imbobo yokulimala kwesendlalelo se-CFRP, kanye nokulimala okugqinsiwe kwebhodi lokujoyina ungqimba lwe-CFRP kungafaniswa lapho isivinini somthelela siyafana futhi siphansi. Indawo yomgodi wesampula yokugcwala okumanzi bukhulu ngokuqhathaniswa. Lokhu kungenxa yokwelashwa kokushisa okumanzi kwenza i-CFRP isendlalelo se-substrate plasticization, i-fiber eyenza buthaka kanye nesixhumi esibonakalayo se-substrate nokusebenza kwe-interlayer, emthelela, isimo sokumanzisa sokushisa kwesifanekiso sokunwetshwa komonakalo owenziwe ngengqimba, ingxenye yomonakalo yanda. Ngokusekelwe ku-Wu Yixuan nezinye izivivinyo ziyazi ukuthi amandla omthelela endleleni yokugandaya eqondile amuncwa ikakhulukazi i-resin substrate, khona-ke i-plasticization ye-substrate yenza isifanekiso sokugcwala esimanzi nesishisayo simunce amandla engeziwe ngesikhathi senqubo yomthelela, sithuthukise ukumelana nomthelela, futhi andise indawo yokuqagela yembobo yomonakalo; Umonakalo we-laminate we-CFRP awuzange unwetshwe ngokugcwele, umthelela usuphelile, ngakho-ke lapho isivinini somthelela siphezulu, ukwelashwa kokushisa okumanzi endaweni yokubonisa umonakalo we-CFRP akusasebi kakhulu, kodwa ngenxa ye-plasticization ye-substrate resin, umthamo wokumuncwa usakhula.

4 Iziphetho

(1) Ngokukhula kwesivinini somthelela, indawo ehlongozwayo yembobo yomonakalo ye-carbon fibre eqiniswe i-epoxy resin composite (CFRP) i-laminate iyakhuphuka, futhi izinga lokukhula lomonakalo ongu-孑L wembobo kusampula kuzinga lokushisa kwegumbi elomile lingaphezulu kwalokho ngaphansi kokugcwala kokushisa okumanzi. Okukhulu: (2) Uma isivinini somthelela singama-45 m/s, indawo ebonisa umonakalo we-CFRP laminate esimweni sokugcwala kokushisa okumanzi inyuka ngo-85. 11%, lapho isivinini somthelela singama-68 m/s, indawo yokuqagela yomonakalo ye-CFRP laminate esimweni sokugcwala ukushisa okumanzi ikhuphuka ngo-18% wegumbi lokushisa elinokushisa kwe-CFRP uma kuqhathaniswa ne-laminate yegumbi elomile. 10%, isivinini somthelela ngu-86m / s. Indawo yokubonisa umonakalo we-laminate ye-cFRP egcwele amanzi yehliswe ngo-9.9% uma iqhathaniswa nezinga lokushisa legumbi elomile le-cFRP laminate. 25%; (3) Ngemva kokuba i-cFRP laminate ithintwa indawo eshisayo neyomswakama, ukusebenza kwe-interlayer ye-laminate kuyancishiswa, okuholela ekwandiseni indawo ye-delamination.

Isikhathi sokuthumela: Jun-24-2019