1 Gabatarwa

Carbon fiber ƙarfafa epoxy composite (CFRP) yana da fa'idodi da yawa kamar ƙarancin ƙima, ƙayyadaddun ƙarfi na musamman, ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙarfi, juriyar gajiya, juriyar lalata da kyawawan kaddarorin inji. Ana amfani da shi sosai a sararin samaniya da sauran tsattsauran yanayi, zafi mai zafi da tasiri. Tasirin abubuwan muhalli akan kayan yana ƙara bayyana. A cikin 'yan shekarun nan, malaman gida da na waje sun gudanar da bincike mai yawa game da tasirin yanayi mai zafi da zafi a kan CFRP composites [1] da kuma tasirin tasirin CFRP. Binciken ya gano cewa tasirin yanayi mai zafi da zafi a kan abubuwan CFRP sun hada da filastik na matrix [2, fashewa [31 da raunin fiber-matrix interface Properties [2'3'5], CFRP composite lankwasawa tare da ƙara yawan lokacin jiyya zafi mai zafi) The inji Properties na wasan kwaikwayon [2, gubar da interlaminar karfi kaddarorin [2, 1 da kuma a tsaye tensile kaddarorin] ya nuna ƙasa. Woldesenbet et al. [8,9] yayi nazarin tasirin kayan aikin injiniya na abubuwan haɗin gwiwa a cikin matsanancin matsanancin zafi bayan jiyya mai zafi, kuma ya sami cewa yanayin zafi da zafi ya inganta tasirin tasirin abubuwan haɗin gwiwa. An bayyana cewa shayar da danshi na kayan haɗin gwiwar zai iya inganta tasirin kayan aikin injiniya a ƙarƙashin wasu yanayi, wanda ya bambanta da sakamakon gwaji a ƙarƙashin yanayi mai mahimmanci. Babban aikin bincike na yanzu shine tasirin zafi mai ɗanɗano (ciki har da nutsar da ruwa) akan ƙarancin tasirin tasirin fiber mai ƙarfafa resin matrix composites. Pan Weng et et al [10] Yin nazarin kaddarorin ƙirar Fiber-biyu na Fiberglass / Epoxy Haɗin kai bayan yanayin zafi da zafi da yanayin zafi (65 ° Cutar ruwa. 4. Ana samun laminate a ƙarƙashin yanayi mai zafi da zafi bayan ƙananan gudu. Ayyukan matsawa yana raguwa sosai. Karasek et al. [1] yayi nazarin tasirin zafi da zafin jiki akan tasirin graphite/exy composites, kuma ya same su a cikin ƙananan zafin jiki da yanayin zafin ɗaki. Danshi yana da ɗan tasiri akan ƙarfin farko da shayar da makamashi na lalacewa. Yucheng zhong et al [12,13] sun yi gwajin tasiri mai ƙarancin sauri akan laminates masu haɗaka bayan jiyya mai zafi. An kammala cewa yanayin zafi da zafi yana rage tasirin tasirin laminate. Inganta tasirin tasirin laminates. Krystyna et al. [14] yayi nazarin ƙananan saurin tasiri na fiber aramid-glass fiber / epoxy composite bayan jiyya mai zafi (70 ° C nutsewar ruwa), kuma ya sami ƙaramin yanki na lalacewa bayan jiyya mai zafi. Wannan yana haifar da lalacewa a cikin samfurin, wanda ke ɗaukar ƙarin kuzari yayin tasiri kuma yana hana samuwar lalata. Ana iya gani daga abin da ke sama cewa tasirin yanayin zafi mai zafi akan tasirin tasirin abubuwan da aka haɗa da haɓaka yana da tasiri mai tasiri da rauni. Don haka, ana buƙatar ƙarin bincike da tabbatarwa. Dangane da tasiri, Mei Zhiyuan et al [15] sun ba da shawara kuma sun kafa tsarin bincike mai zurfi na matakai biyu (shigarwa mai tsauri da ci gaba da shiga ciki) ƙirar ƙira mai ƙarfi na fiber-ƙarfafa haɗaɗɗun laminates a ƙarƙashin tasiri mai sauri. Guiping Zhao et al. [16] conducted three kinds of different speeds (less than, equal to and greater than the ballistic limit speed) on the impact performance and damage of the specimen after three kinds of laminates, but did not involve the impact of the moist heat environment on the impact damage. . Dangane da wallafe-wallafen da ke sama, binciken da ya danganci tasirin yanayin jika da zafi a kan fiber ƙarfafa haɗakar laminates ba a ci gaba da bincike ba. A cikin wannan takarda, an yi nazarin halayen lalacewar rigar zafi cikakken carbon fiber/epoxy composite laminates ƙarƙashin yanayin wanka na ruwa 70 °C. An yi nazarin tasirin yanayi mai zafi da zafi a kan tasirin gazawar halaye na abubuwan haɗin gwiwa ta hanyar kwatanta da samfuran zafin jiki na bushewa. A cikin gwaji, an yi amfani da laminates na CFRP akan laminates na CFRP a 45 m / s, 68 m / s da 86 m / s. An auna saurin kafin da kuma bayan tasirin. An yi nazarin tasirin yanayin zafi da zafi a kan aikin shayar da makamashi na laminates. An yi amfani da c-scan na Ultrasonic don gano lalacewar ciki na laminate, kuma an yi nazarin tasirin tasirin tasirin tasiri akan yankin da aka rushe. An yi amfani da microscope na lantarki da na'ura mai kwakwalwa mai zurfi-zurfi mai zurfi-zurfi mai girma uku don lura da halayen mesoscopic na lalacewar samfurin, kuma an yi nazarin lalacewar samfurin ta wurin yanayin zafi mai zafi. Tasirin fasali.

2 Kayan gwaji da hanyoyin

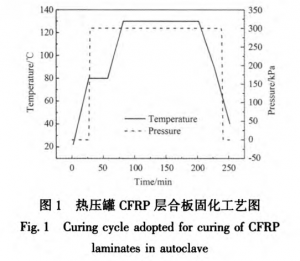

2. 1 Kayan abu da shiri

Carbon fiber epoxy guduro (T300 / EMl 12) hada abubuwa, pre-nitsuwa bayar da Jiangsu Hengshen Co., Ltd., guda-Layer pre-nitsewa kauri na 0. 137 mm tare da fiber girma juzu'i na 66%. An shimfiɗa laminate panel a ƙasa na Layer. , girman 115mm x 115mln. Ana amfani da tsarin samar da tanki mai zafi. An nuna zane-zanen tsarin warkarwa da aka shirya a cikin Hoto 1. Da farko tada gida daga dakin da zafin jiki zuwa 80 oC a yanayin zafi na 1 zuwa 3 oC / min, sa'an nan kuma ci gaba da dumi na minti 30, zafi zuwa 130 oC a yanayin zafi na l13 oC / min, dumi a 120 min, rage zuwa 60.0C a akai-akai yawan sanyaya, sa'an nan kuma cire matsa lamba da saki, da saki.

2. 2 Jikin zafi mai zafi

Bayan shirye-shiryen samfurin, an yi maganin rigar-zafi daidai da ƙayyadaddun HB 7401-96.171 "Hanyar gwaji ta hanyar gwaji na tushen guduro mai haɗe-haɗe-haɗe-haɗe-haɗe-haɗe-haɗe-haɗe". Na farko, ana sanya samfurin a cikin ɗakin bushewa na thermostatic a digiri 70 na C don bushewa. Yin la'akari akai-akai ta yin amfani da ma'auni har sai asarar ingancin samfurin ya kasance barga fiye da 0. 02%, ƙimar da aka rubuta a wannan lokacin shine Injiniya Dry Mass G. Bayan bushewa, ana sanya samfurin a cikin 70 digiri C na ruwa don maganin zafi mai zafi. Dangane da ƙayyadaddun HB 7401. Hanyar da aka kayyade a cikin 96 "yana auna ingancin samfurin kowace rana, wanda aka rubuta a matsayin Gi, kuma yana yin rikodin canjin shayar da danshi Mi. Maganar shayar da danshi na samfurin laminate CFRP shine:

Dalla-dalla dabarar: Mi shine shayar da danshi na samfurin, Gi shine inganci bayan samfurin ya sha danshi, g, tafi shine ingancin yanayin bushewar injin samfurin.

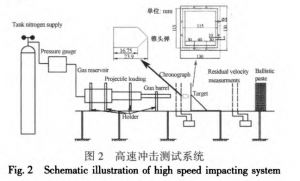

2. 3 Tasiri Gwaje-gwaje

An yi gwajin tasirin tasiri mai sauri a kan laminate na CFRP a kan madaidaicin iska mai sauri tare da diamita na 15 mm. Na'urar gwajin tasiri mai sauri (duba Hoto 2) ya haɗa da bindigar iska mai sauri, na'urar auna saurin laser kafin da bayan tasiri, jikin harsashi, samfurin shigarwa (kusurwar dama na Hoto 2), da na'urar dawo da lafiyar harsashi. Jikin harsashi harsashi ne na silindrical mai kai mazugi (Hoto na 2), kuma girman harsashi shine 24. 32 g tare da diamita na 14. 32 mm; Gudun tasiri shine 45 m / s (tasirin makamashi 46 J), 68 m / s (tasirin makamashi 70 J), 86 m / s (tasirin makamashi 90 J).

2. 4 Gane lalacewa na samfurori

Bayan da tasirin ya shafa, ana amfani da nau'in nau'in fiber na carbon fiber epoxy composite composite laminate Layer edgout farantin don gano lalacewar tasirin ciki na CFRP laminate farantin, kuma ana auna yankin tsinkayar tasirin tasirin ta hanyar software na bincike na hoto UTwim, kuma ana lura da cikakkun fasalulluka na ɓarna ɓarna ta hanyar duba microscope na lantarki da ultra-depth na microscopic filin.

3 Sakamako da tattaunawa

3. 1 Samfuran halayen sha da danshi

Jimlar 37. 7 d, matsakaita na cike da danshi shine 1. 780%, tare da adadin watsawa na 6. 183x10. 7llnl2/s. An nuna ma'aunin shayar da danshi na samfurin laminate na CFRP a cikin Hoto na 3. Kamar yadda za a iya gani daga Hoto na 3, farkon girma girma na danshi na samfurin yana da linzamin kwamfuta, bayan mataki na layi, yawan ci gaban daɗaɗɗen danshi ya fara raguwa, ya kai matsayi mai tsayi bayan kimanin 23 d, da kuma kaiwa ga lokacin sha na danshi. Sabili da haka, shayar da danshi na samfurin ya dace da yanayin shayar da danshi mai matakai biyu: mataki na farko na shayar da danshi saboda aikin haɗin gwiwa na zafin jiki da zafi, danshi ta hanyar kayan da kanta ya ƙunshi pores, ramuka, fasa da sauran lahani da aka yada zuwa cikin kayan; Yaduwar ruwa yana sannu a hankali kuma sannu a hankali ya kai jikewa a wannan matakin.

3. Halayen lalacewa na bayyane na katako na laminate 2-Layer

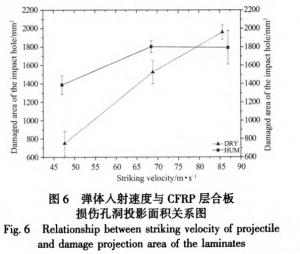

Gudun tasiri na 86 m / s lokacin da samfurin gaba, baya na taswirar bayanin martaba na lalacewa, ta wurin busassun dakin zafi samfurin, rigar zafi jikewa samfurin gaban halakar siffar ya fi kama, samfurori guda biyu a cikin tasiri, saboda fashewar tushe, lalata ta tare da farkon Layer na fiber yana da wani zamewa. Wannan yana sa gaba ya zama siffa mai siffar elliptical ko rectangular, kuma baya ga iya ganin tsagewar da ke cikin ƙwanƙolin, za a iya ganin firam ɗin ya karye. Ta wurin busassun samfurin zafin jiki na dakin, samfurin jikewa mai zafi mai zafi a baya na lalata siffar za a iya ganin cewa baya tare da jagorancin tasiri yana da wani kumburi, kuma yana gabatar da tsattsauran nau'i na giciye. A bayyane yake cewa ɓarkewar fiber, fashewar tushe da ɓarnawar interlayer (laying) nau'ikan ɓarna guda uku, ɓangaren ƙarshe na fiber yana ɗagawa amma ba a karye ba, kawai shimfidawa da fashe fiber / tushe. Har ila yau, raunin fiber ya bambanta, kamar yadda ake iya gani daga kwatanta lalacewar gaba da baya. Gaban yana haifar da karyewar fiber da substrate saboda matsawa da tsagewa. Baya saboda mikewa ne ya sa fiber ya karye kuma ya yi shimfida da substrate. Hoto na 4 shine saurin girgiza na 45 m/s, 68 m/s, 86 m/s lokacin da samfurin lalacewa na ciki C scan. Wurin da aka nuna ta kusan layin zagaye l launin toka a tsakiyar adadi shine yanki da aka tsara na rami mai lalacewa. Layin baƙar fata a sama da ƙasa kowane ƙaramin ginshiƙi yana nuna wurin wurin bawon baya na samfurin. Wurin da aka yiwa alama a cikin farin layi a cikin adadi (b) (d) (f) shine lalacewar ciki ga samfurin tare da iyaka. Jadawalin ya nuna cewa tasirin tasirin yana ƙaruwa yayin da saurin tasirin ya karu. Farantin laminated yana iya ɗaukar ƙarin kuzari yayin tasiri (duba Hoto 6 don takamaiman ƙima), yana haifar da haɓaka yanki na tsinkayar lalacewar laminate: ta hanyar kwatanta busassun samfurin zafin jiki tare da hoton jikewar jikewar jikewa, ana iya ganin cewa akwai lalacewa na ciki (fararen layin) na samfurin da aka samar tare da iyaka a cikin jika na yanayin zafi mai zafi, yanayin yanayin zafi. Ƙarƙashin ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar cuta ta haifar da iyaka don samun wani tasiri a kan farantin laminate yayin aiwatar da tasiri. Bisa ga adadi, yankin bawon baya (baƙar layi) na samfurin a cikin busassun yanayi bai bambanta da yanayin jikewa mai zafi ba.

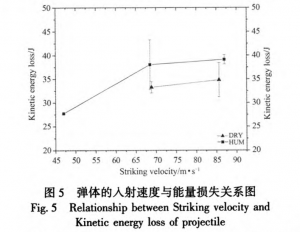

3. Cikakken fasali na ɓarna na 3-Layer panel

Taswirar taswirar ɓarna na ɓangarori na CFRP Layer farantin haɗin gwiwa, wanda tsarin 3D mai zurfi mai zurfi ya ɗauka da kuma madubin lantarki na dubawa, tare da saurin tasiri na 45 m / s, bushe da rigar da zafi, ya nuna cewa lalacewar samfurin a cikin jihohin biyu ya haɗa da nau'i uku na lalata: fashewar fiber, fashewar tushe da fashewar interlayer. Amma tushen samfuran biyu ya fashe daban. Ƙarƙashin ƙwayar ƙwayar cuta a cikin busassun yanayi yana raguwa a haɗin tsakanin fiber da substrate. Duk da haka, fashewa na substrate bayan jiyya na zafi mai zafi yana tare da gutsuttsuran da ke fadowa. Wold-esenbet da sauran kayan a cikin rigar da zafi yanayi na tasiri yi na tsarin da tsarin da fiber substrate dubawa ƙasƙanci tare m, a cikin rigar zafi yanayi, CFRP Layer farantin a cikin guduro tushe gwaninta sha wani adadin ruwa, seeping ruwa zai sa da guduro substrate to narke. Carbon fiber ba ya sha, to, dole ne a sami fadada rigar tsakanin su biyun, wannan bambanci yana raunana haɗin tsakanin ma'auni da fiber, yana rage ƙarfin substrate. Lokacin da aka ƙaddamar da nauyin tasirin tasiri, ana iya sauke ɓangarorin substrate cikin sauƙi, wanda ya haifar da bambanci daga wurin bushewar ɗakin zafin jiki na lalacewa. Daga cikakken tsarin madubin wutar lantarki da aka nada, za a iya gane cewa tsagewar jika da zafin jiki na bayan gida shi ne fashewar hutun manema labarai, yayin da tsagewar kafin zafin rana ya fi karye, kuma tsagewar kwancen da ke tsakanin layuka ya fi fitowa fili. Daga microscope na gani a cikin adadi, ana iya ganin cewa nau'ikan lalacewa sun bambanta a cikin lokuta biyu, kuma bushewar yanayi shine lalacewa ta hanyar yankewa. Don yanke lalacewar musamman, bayan daɗaɗɗen zafi don nau'in lalacewa tare da gagarumin lalacewa mai laushi, rabon lalacewa ya karu. Ana iya ganin shi daga kusurwar tsarin lalata da halayen haɓaka makamashi. Mei Zhiyuan ya gabatar da matakai biyu na mamayewar: matakin yankewa da ci gaba da mamayewa. A yankin a cikin rigar zafi samfurin ne karfi kutsawa mataki halaka, yafi saboda a cikin tasiri tsari, da Layering farantin da aka matsa da sheared samuwar lalata lalata, b yankin ne ci gaba mamaye mataki halaka. Wannan matakin ya fi girma saboda raguwar saurin kutsawa cikin jikin harsashi a ƙarƙashin aikin shimfidar damuwa na ɓangaren fibrous Layer, kuma makamashin ya fi jujjuya shi zuwa cikin ƙarfin ƙarfin fiɗaɗɗen fiber da ƙarfin fashewar interlayer (l 51), ta yadda fiber ya karya el da raunin fiber da ya gabata ba su cikin layi madaidaiciya. A cikin samfurin busassun, wannan lamari ba a bayyane yake ba, kuma lalacewar farantin ya fi tsanani, Layer Layer yana da yanayin fashewa. 3. 4 Cutar makamashi da lalacewar yanki na bincike na Welassi Gane-canje 5 yana nuna alaƙar da ke tsakanin jikin mutum, a cikin saurin zazzabi na kananan sake farfadowa, don haka ba a nuna a cikin adadi ba. Kamar yadda ake iya gani daga Hoto na 7, lokacin da aka gwada gwajin a ƙarƙashin jikewar thermal jikewa, asarar makamashin harsashi yana da tsanani, kuma ƙarfin tsotsa samfurin bayan jiyya na zafi yana ƙaruwa.

Hoto 6 hoto ne na jadawali na yanki na tsinkaya na saurin abin da ya faru na harsashi da rami na lalacewa na CFRP (layin launin toka alama sashi na Figure 4), cikakken adadi (4), (5), (6) ana iya gani: (1) tare da haɓaka saurin tasiri, yankin CFRP Layer Layer lalata rami tsinkayar yanki yana ƙaruwa; (3) lokacin da saurin tasiri ya kasance game da 45 m / s, yanki na tsinkaya na lalacewa na laminated farantin bayan rigar zafi jiyya ya fi girma fiye da tsinkaya yanki na laminated farantin lalacewa rami a bushe dakin zazzabi jihar. Wet thermal jikewa samfurin lalacewa l-rami tsinkaya yanki ya karu da 85. 1% kuma a wani girgiza gudun game da 68 m / s, da laminated farantin a cikin wani rigar da thermal jikewa jihar ya karu da 18. 10%, da sha darajar (Figure 5) ya karu da 15. 65%; A saurin tasiri na kusan 88 m / s, farantin laminated a cikin rigar da yanayin jikewa na thermal an rage shi da 9. 25%, ƙimar sha har yanzu ta karu da 12. 45%.

Dangane da sakamakon bincike na Yucheng Zhong da sauran kayayyakin, damshin da ake samu na carbon fiber-ƙarfafa kayan haɗakarwa yana haɓaka iyakacin ƙarfi da juriya na tasirin laminate, kuma yana haɗa yankin da aka yi hasashen rami rami na busasshen yanayin zafin ɗakin da kuma samfurin jikewar jikewa a cikin wannan takarda (Hoto na 4) a cikin layin da ya faru a cikin zane-zanen hoto. yanki na ramin lalata Layer Layer CFRP, kuma ana iya kwatanta lalacewa mai laushi na CFRP Layer haɗuwa jirgin lokacin da tasirin tasirin ya kasance iri ɗaya da ƙasa. Wurin lalacewa na jikakken samfurin jikewa mai zafi yana da girma. Wannan shi ne saboda da rigar zafi jiyya sa CFRP Layer substrate plasticization, raunana fiber da substrate dubawa da interlayer yi, a cikin tasiri, da rigar zafi jikewa jihar na samfurin Layered lalacewar lalacewa, da rabo daga lalacewa ya karu. Bisa ga Wu Yixuan da sauran gwaje-gwajen sun san cewa tasirin makamashi a cikin hanyar shimfidar shimfidar wuri ya fi shayar da shi ta hanyar resin substrate, sa'an nan kuma sanya filastik na substrate yana sa samfurin jikewa na jike da zafi ya sha karin makamashi a yayin aiwatar da tasiri, yana inganta juriya na tasiri, kuma yana kara yawan tsinkayar ramin lalacewa; Lalacewar laminate na CFRP ba ta cika ba, tasirin ya ƙare, don haka lokacin da saurin tasiri ya fi girma, jiyya mai zafi a kan CFRP laminate tsinkaya tsinkayar tsinkaya ba ya da tsanani, amma saboda plasticization na substrate resin, da ikon iya har yanzu ya karu.

4 Ƙarshe

(1) Tare da karuwar tasirin tasiri, yankin da aka tsara na lalacewar rami na carbon fiber ƙarfafa epoxy resin composite (CFRP) laminate yana ƙaruwa, kuma girman girman lalacewa 孑L rami a cikin samfurin a bushe dakin zafin jiki ya fi girma fiye da cewa a karkashin rigar zafi jikewa. Babban: (2) Lokacin da saurin tasiri ya kasance 45 m / s, lalacewar tsinkayar lalacewa na CFRP laminate a cikin yanayin jikewar zafi mai zafi ya karu da 85. 11%, lokacin da tasirin tasiri ya kasance 68 m / s, lalacewar tsinkayar yanki na CFRP laminate a cikin rigar zafi jikewa jihar ya karu da 18% bushe yanayin yanayin zafi idan aka kwatanta da yanayin zafi na 1CFRP. 10%, saurin tasirin shine 86m / s. An rage jika-cikakken-cikakken yanki tsinkayar lalacewar laminate 9.9% idan aka kwatanta da busasshen zafin dakin cFRP laminate. 25%; (3) Bayan laminate cFRP ya shafi yanayin zafi da zafi, aikin interlayer na laminate ya ragu, yana haifar da fadada yankin delamination.

Lokacin aikawa: Juni-24-2019