1 Okwu mmalite

Carbon fiber mesiri epoxy composite (CFRP) nwere ọtụtụ uru dị ka obere njupụta, elu kpọmkwem ike, elu kpọmkwem isiike, ike ọgwụgwụ, nguzogide corrosion na ezi n'ibu Njirimara. A na-ejikarị ya eme ihe na mbara igwe na ihe ndị ọzọ na-eme ihe ike gburugburu ebe obibi, okpomọkụ na-ekpo ọkụ na mmetụta. Mmetụta nke ihe gburugburu ebe obibi na ihe onwunwe na-apụtawanye ìhè. N'ime afọ ndị na-adịbeghị anya, ndị ọkà mmụta ụlọ na ndị mba ọzọ emeela ọnụ ọgụgụ dị ukwuu nke ọmụmụ banyere mmetụta nke gburugburu ebe obibi na-ekpo ọkụ na iru mmiri na CFRP composites [1] na mmetụta nke mmetụta na CFRP composites. Nnyocha ahụ chọpụtara na mmetụta nke na-ekpo ọkụ na iru mmiri na gburugburu ebe obibi na CFRP composites gụnyere plasticization nke matrix [2, cracking [31 na ike ọgwụgwụ fiber-matrix interface Njirimara [2'3'5], CFRP mejupụtara ekwe na-amụba wet okpomọkụ ọgwụgwọ oge) The n'ibu Njirimara nke arụmọrụ [2, ndu na interlaminar shiee Njirimara [2, 1 na static tensile Properties] gosiri ala [3'. Woldesenbet et al. [8,9] mụọ mmetụta ihe eji arụ ọrụ nke ihe ndị mejupụtara na ọnụ ọgụgụ dị elu mgbe ọgwụgwọ okpomọkụ gasịrị, wee nweta na ebe dị ọkụ na iru mmiri na-eme ka mmetụta nke ihe ndị ahụ dịkwuo mma. Ọ na-ekpughe na mmiri absorption nke ihe mejupụtara nwere ike melite mmetụta n'ibu Njirimara nke ihe n'okpuru ụfọdụ ọnọdụ, nke dị nnọọ iche na ibuo pụta n'okpuru quasi-static ọnọdụ. Isi ọrụ nyocha dị ugbu a bụ mmetụta nke mmiri na-ekpo ọkụ (gụnyere imikpu mmiri) na mmetụta mmetụta dị ala nke ihe mejupụtara matrix resin fiber. Pan Wenge et al [10] mụrụ ihe mkpakọ mkpakọ nke fiberglass akụkụ abụọ kpara akpa/epoxy composite laminates mgbe mmetụta dị ala na-adị na ụlọ okpomọkụ na n'okpuru ọnọdụ okpomọkụ na iru mmiri (65 Celsius C imikpu mmiri). 4. A na-enweta laminate n'okpuru ebe a na-ekpo ọkụ ma na-ekpo ọkụ mgbe obere ngwa ngwa. A na-ebelata arụmọrụ mkpakọ nke ukwuu. Karasek et al. [1] mụọ mmetụta nke iru mmiri na okpomọkụ na mmetụta nke graphite/epoxy composites, wee nweta ha na obere okpomọkụ na gburugburu ụlọ okpomọkụ. Iru mmiri na-enwe mmetụta dị nta na ike mbụ na ike nnabata nke mmebi ahụ. Yucheng zhong et al [12,13] mere ule mmetụta dị ala dị ala na laminates mejupụtara mgbe ọgwụgwọ okpomọkụ gasịrị. A na-ekwubi na gburugburu ebe na-ekpo ọkụ na iru mmiri na-ebelata mmetụta nke mmebi nke laminate ahụ. Melite nguzogide mmetụta nke laminates. Krystyna et al. [14] mụrụ mmetụta dị ala nke aramid-glass fiber / epoxy composite mgbe ọgwụgwọ mmiri dị mmiri (70 Celsius C na-emikpu mmiri), wee nweta mpaghara mmebi obere mmetụta mgbe ọgwụgwọ mmiri gasịrị. Nke a na-ebute mmebi delamination n'ime ihe nlele ahụ, nke na-etinyekwu ume n'oge mmetụta ma na-egbochi nhazi nke delamination. Enwere ike ịhụ site na nke dị n'elu na mmetụta nke ebe okpomọkụ na-ekpo ọkụ na-emetụta mmetụta mmebi nke ihe ndị mejupụtara nwere mmetụta na-akwalite ma na-ebelata ike. Ya mere, a chọrọ nyocha ọzọ na nkwenye. N'ihe gbasara mmetụta, Mei Zhiyuan et al [15] tụpụtara ma guzobe usoro nyocha nke usoro abụọ (ịcha penetration na ntinye na-aga n'ihu) ntinye ihe nleba anya nyocha nke eriri na-eme ka ihe mejupụtara ya dị elu n'okpuru mmetụta ọsọ ọsọ. Guiping Zhao et al. [16] mere ụdị ọsọ ọsọ atọ dị iche iche (ihe na-erughị, hà nhata ma dị ukwuu karịa oke ịgba ọsọ ballistic) na arụmọrụ mmetụta na mmebi nke ihe atụ ahụ mgbe ụdị atọ nke laminates gasịrị, ma ọ bụghị na-emetụta mmetụta nke ebe okpomọkụ na-ekpo ọkụ na mmebi mmetụta. . Dabere na akwụkwọ ndị a dị n'elu, nchọpụta metụtara ya na mmetụta nke mmiri na gburugburu ebe obibi na-ekpo ọkụ na fiber na-eme ka laminates composite na-eme ka ọ dịkwuo ike ka enyochabeghị. N'akwụkwọ a, a mụrụ mmetụta mmebi àgwà nke mmiri ọkụ jupụtara carbon fiber/epoxy composite laminates n'okpuru ọnọdụ ịsa mmiri 70 Celsius. A tụlere mmetụta nke gburugburu na-ekpo ọkụ na iru mmiri na mmetụta ọdịda njirimara nke ngwakọta site na atụnyere ihe nlele okpomọkụ ụlọ akọrọ. N'ime nnwale ahụ, a na-emetụta CFRP laminates na CFRP laminates na 45 m / s, 68 m / s na 86 m / s. A tụrụ ọsọ tupu na mgbe mmetụta ahụ gasịrị. A na-enyocha mmetụta nke gburugburu ebe obibi na-ekpo ọkụ na iru mmiri na arụmọrụ ike nke laminates. A na-eji Ultrasonic c-scan chọpụta mmebi nke ime nke laminate ahụ, a na-enyochakwa mmetụta nke mmetụta ọsọ ọsọ na mpaghara gbajiri agbaji. A na-eji microscope eletrọn na-enyocha ihe na ultra-depth-depth microscopic system microscopic akụkụ atọ iji hụ njirimara mesoscopic nke mmebi ihe nlele ahụ, a na-enyocha mmebi nke ihe nlele ahụ site na ebe okpomọkụ iru mmiri. Mmetụta nke atụmatụ.

2 Ngwa na ụzọ nnwale

2. 1 Ihe na nkwadebe

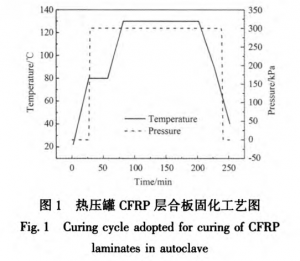

Carbon eriri epoxy resin (T300 / EMl 12) mejupụtara ihe, tupu immersion nyere site Jiangsu Hengshen Co., Ltd., otu oyi akwa tupu imikpu ọkpụrụkpụ nke 0. 137 mm na eriri olu nta nke 66%. A na-etinye panel nke laminate n'elu ala nke oyi akwa. , nha 115mm x 115mln. A na-eji usoro nhazi nke tankị na-ekpo ọkụ. E gosipụtara eserese usoro ọgwụgwọ nke a kwadebere site na usoro ahụ na Figure 1. Buru ụzọ bulie ụlọ site na ọnụ ụlọ okpomọkụ ruo 80 oC na ọkụ ọkụ nke 1 ruo 3 oC / min, wee na-ekpo ọkụ maka 30 min, okpomọkụ na 130 oC na ọkụ ọkụ nke l13 oC / min, na-ekpo ọkụ na 120 min, belata ruo 60.0C na ọnụego jụrụ oyi mgbe niile, wee wepụ nrụgide na ntọhapụ, ma hapụ ya.

2.2 ọgwụgwọ mmiri mmiri

Mgbe emechara ihe nlere ahụ, a na-edozi ihe nlele mmiri mmiri-okpomọkụ dị ka nkọwapụta HB 7401-96.171 si dị na nkọwapụta "Resin-based composite composite composite layer wet hot environment water absorption usoro nnwale". Nke mbụ, a na-etinye ihe atụ ahụ n'ime ụlọ ikpo ọkụ na-ekpo ọkụ na 70 degrees C iji kpoo. Na-atụ aro mgbe niile na-eji nguzozi ruo mgbe ịdị mma nke ihe atụ ahụ kwụsiri ike na ọ dịghị ihe karịrị 0. 02%, ọnụ ahịa e dekọrọ n'oge a bụ Engineering Dry Mass G. Mgbe ihichachara, a na-etinye ihe nlele ahụ na 70 degrees C nke mmiri maka ọgwụgwọ mmiri ọkụ. Dị ka nkọwapụta HB 7401. Usoro akọwapụtara na 96 "na-atụle ịdị mma nke ụdị ahụ kwa ụbọchị, dekọrọ dị ka Gi, ma na-edekọ mgbanwe nke mmiri absorption Mi. Okwu absorption nke mmiri nke CFRP laminate specimen bụ:

A kọwapụtara usoro a: Mi bụ mmịpụta mmiri nke ụdị ahụ, Gi bụ mma mgbe ihe nlele ahụ na-amịkọrọ mmiri, g, aga bụ ogo ala nkụ nke injinịa ihe atụ.

2. 3 Nnwale mmetụta

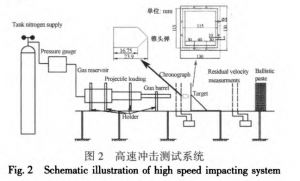

A na-eme nnwale mmetụta ọsọ ọsọ na CFRP laminate na ikuku ikuku na-agba ọsọ na dayameta nke 15 mm. Ngwa nnwale mmetụta ọsọ ọsọ dị elu (lee eserese 2) gụnyere egbe ikuku na-agba ọsọ dị elu, ngwaọrụ nha ọsọ laser tupu na mgbe ọ gafesịrị, ahụ mgbọ, ihe nrụnye ihe nrụnye (akụkụ aka nri nke ọnụ ọgụgụ 2), na ngwaọrụ mgbake ahụ mgbọ. Ahụ mgbọ bụ mgbọ cylindrical nke nwere isi cone (Nkeji 2), na olu nke mgbọ bụ 24. 32 g nke nwere dayameta nke 14. 32 mm; mmetụta ọsọ bụ 45 m / s (mmetụta ike 46 J), 68 m / s (mmetụta ike 70 J), 86 m / s (mmetụta ike 90 J).

2. 4 Nchọpụta mmebi nke ụdịdị

Mgbe mmetụta ya na-emetụta ya, a na-eji carbon fiber color epoxy composite composite laminate Layer edgout efere iji chọpụta n'ime mmetụta mmebi nke CFRP laminate efere, na ntule mpaghara nke mmetụta mmebi a na-atụ site image analysis software UTwim, na zuru ezu atụmatụ nke cross-ngalaba mbibi na-hụrụ site scanning eletrọn microscope na ultra-depth microscopic ubi.

3 Nsonaazụ na mkparịta ụka

3. 1 Ihe atụ njirimara absorption nke mmiri

Ngụkọta nke 37. 7 d, nkezi nke nnabata mmiri juru eju bụ 1. 780%, yana ọnụego mgbasa nke 6. 183x10. 7llnl2/s. A na-egosi usoro mmịpụta mmiri nke CFRP laminate specimen na Figure 3. Dị ka a pụrụ ịhụ site na foto 3, mmalite uto nke mmiri absorption nke ihe atụ bụ linear, mgbe linear ogbo, uto ọnụego nke mmiri absorption na-amalite ibelata, na-eru a guzo larịị ala mgbe ihe dị ka 23 d, na-erute saturation mmiri mmiri mgbe oge absorption. Ya mere, mmịpụta mmiri nke ihe atụ ahụ kwekọrọ na ọnọdụ absorption nke okpukpu abụọ: ọkwa mbụ nke ntinye mmiri bụ n'ihi njikọ nkwonkwo nke okpomọkụ na iru mmiri, mmiri site na ihe ahụ n'onwe ya nwere pores, oghere, cracks na ntụpọ ndị ọzọ na-agbasa n'ime ihe ahụ; Mgbasa mmiri na-adị nwayọọ ma jiri nwayọọ nwayọọ rute saturation n'oge a.

3. Njirimara mbibi pụtara ìhè nke 2-layer laminate board

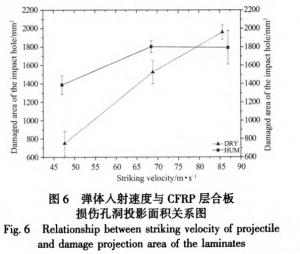

Mmetụta ọsọ nke 86 m / s mgbe ihe nleba anya n'ihu, azụ nke map profaịlụ mbibi pụtara ìhè, site na ihe nlele ụlọ okpomọkụ nke akọrọ, mmiri ọkụ saturation n'ihu mbibi udi dị ka, ihe atụ abụọ na mmetụta, n'ihi na ntọala cracks, ya mbibi tinyere mbụ oyi akwa nke eriri nwere ụfọdụ slip. Nke a na-eme ka ihu na-eme ka ọdịdị elliptical ma ọ bụ akụkụ anọ, na mgbakwunye na inwe ike ịhụ mgbawa na mkpụrụ, a pụrụ ịhụ ka eriri ndị ahụ gbajiri. Site akọrọ ụlọ okpomọkụ sample, udu mmiri na-ekpo ọkụ saturation sample na azụ nke mbibi nke udi nwere ike hụrụ na azụ tinyere mmetụta direction nwere ụfọdụ ntoputa, na ọnọde cross-ekara mgbape. O doro anya na eriri eriri eriri, mgbawa isi na mgbawa interlayer (laying) ụdị atọ nke mbibi, a na-ebuli akụkụ ikpeazụ nke eriri ahụ ma ọ bụghị agbaji, naanị ịkwa akwa na eriri / isi mgbawa. Ọkpụkpụ eriri ahụ dịkwa iche, dịka enwere ike ịhụ site na ntụnyere nke mmebi ihu na azụ. N'ihu na-akpata mgbaji nke eriri na mkpụrụ n'ihi mkpakọ na ịkwa akwa. Azụ bụ n'ihi ịgbatị ahụ mere ka eriri ahụ gbajie wee dochie mkpụrụ. Ọgụgụ 4 bụ oke ujo nke 45 m/s, 68 m/s, 86 m/s mgbe ihe nleba anya mebiri C. Ebe e gosipụtara site na gburugburu gburugburu l gray akara dị n'etiti ọnụ ọgụgụ ahụ bụ ebe a na-atụ anya nke oghere mmebi ahụ. Ahịrị ojii dị n'elu na n'okpuru obere chaatị ọ bụla na-egosi ebe maka mpaghara peeling azụ nke ihe atụ. Ebe akara n'ahịrị ọcha na ọnụọgụ (b) (d) (f) bụ mmebi nke ime n'ime ụdị n'akụkụ oke. Eserese na-egosi na ike mmetụta na-abawanye ka ọsọ nke mmetụta na-abawanye. The laminated efere na-enwe ike itinyekwu ume n'oge mmetụta (lee Figure 6 maka kpọmkwem ụkpụrụ), na-akpata na-amụba ebe nke laminate mmebi amụma: site na-atụnyere akọrọ ụlọ okpomọkụ sample na foto nke mmiri ọkụ saturation ụdị, ọ pụrụ ịhụ na e nwere esịtidem mmebi (ọcha ahịrị) nke ụdị emepụtara n'akụkụ ókè na mmiri nke na-ekpo ọkụ na-ekpo ọkụ na-ekwu na isi usoro saturation. Ntucha nke mkpụrụ osisi na efere laminate na ike ọgwụgwụ nke eriri-base interface na-eme ka ókè ahụ nwee mmetụta ụfọdụ na efere laminate n'oge usoro mmetụta. Dị ka ọnụ ọgụgụ ahụ si kwuo, mpaghara azụ azụ (akara ojii) nke ihe atụ na ọnọdụ akọrọ adịghị iche na ọnọdụ saturation mmiri na-ekpo ọkụ.

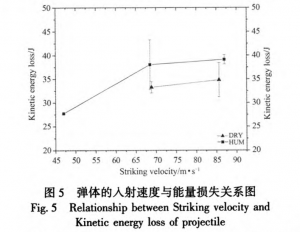

3. Atụmatụ mbibi zuru ezu nke panel 3-layer panel

The cross-section mmebi atụmatụ map nke CFRP oyi akwa efere efere, ewe site ultra-omimi 3D microsystem na scanning eletrọn mirror, na mmetụta ọsọ nke 45 m / s, akọrọ na mmiri na-ekpo ọkụ, na-egosi na mmebi nke ụdịdị na steeti abụọ na-agụnye atọ ụdị mbibi: eriri mgbaji, isi cracking na interlayer fracture. Ma isi nke ihe atụ abụọ ahụ gbawara n'ụzọ dị iche. Ihe mgbawa nke mkpụrụ osisi na ala akọrọ na-agbaji na njikọ dị n'etiti eriri na mkpụrụ. Otú ọ dị, mgbawa nke mkpụrụ ahụ mgbe ọgwụgwọ mmiri mmiri na-ekpo ọkụ na-esonyere iberibe nke mkpụrụ ahụ na-adapụ. Wold-esenbet na ihe ndị ọzọ na mmiri na-ekpo ọkụ na gburugburu ebe obibi nke mmetụta arụmọrụ nke Ọdịdị nke Ọdịdị na eriri substrate interface mmebi ọnụ kpebisiri ike, na mmiri ọkụ na gburugburu ebe obibi, CFRP oyi akwa efere na resin isi ahụmahụ absorption nke a ụfọdụ ego nke mmiri, seeping mmiri ga-eme ka resin mkpụrụ igbari. Carbon fiber anaghị etinye uche, mgbe ahụ, a ga-enwerịrị mgbasawanye mmiri n'etiti abụọ ahụ, ọdịiche a na-ebelata interface n'etiti mkpụrụ na eriri, na-ebelata ike nke mkpụrụ. Mgbe doro mmetụta ibu, ndị mkpụrụ iberibe na-adị mfe ama esịn pụta, dapụtara a dị iche na akọrọ ụlọ okpomọkụ sample mmebi interface. Site zuru ezu Ọdịdị nke scanned electric mirror, ọ pụrụ ịhụ na cracking nke mmiri na-ekpo ọkụ post-isi ahu bụ tumadi rụrụ cracking nke pịa ezumike, mgbe cracking tupu mmiri okpomọkụ bụ tumadi kenkuwa, na kehoraizin shiee mgbape n'etiti n'ígwé bụ ihe doro anya. Site na microscope anya na ọnụ ọgụgụ ahụ, a pụrụ ịhụ na ụdị mbibi ahụ dị iche iche na ikpe abụọ ahụ, na ala akọrọ bụ mbibi nke ọ bụla. Iji belata mbibi ahụ tumadi, mgbe okpomọkụ dị mmiri maka ụdị mbibi na-esonyere mbibi dị egwu, oke mbibi nke oyi akwa gbasaa. Enwere ike ịhụ ya site na akụkụ nke usoro mbibi na njirimara absorption ike. Mei Zhiyuan weputara uzo abuo nke mbuso agha ahu: ogbo mbelata na ogbo mbuso agha na-aga n'ihu. The A ebe na mmiri na-ekpo ọkụ sample bụ shiee intrusion ogbo mbibi, tumadi n'ihi na na mmetụta usoro, na layering efere na-abịakọrọ na sheared guzobe nke mbibi deformation, b ebe bụ na-aga n'ihu mbuso agha ogbo mbibi. Nke a na ogbo bụ tumadi n'ihi Mbelata nke mgbọ ahu intrusion ọsọ n'okpuru edinam nke gbatịa nchegbu akụrụngwa nke fibrous oyi akwa, na ike bụ tumadi converted n'ime eriri gbatịa nje ike na interlayer mgbaji ike (l 51), nke mere na eriri agbaji el na gara aga eriri ezumike adịghị na a ogologo ahịrị. N'ihe atụ akọrọ, ihe omume a adịghị egosi, na mmebi nke efere ahụ dị njọ karị, efere oyi akwa nwere ọnọdụ mgbawa. 3. 4 Absorption ike na mmebi nke amụma mpaghara analysis Figure 5 na-egosi mmekọrịta dị n'etiti akọrọ ụlọ okpomọkụ na mmiri na-ekpo ọkụ saturation nke igba egbe ọsọ na ume ọnwụ nke ahu, na merenụ ọsọ nke banyere 45 m / s, akọrọ ụlọ okpomọkụ nke mgbọ niile rebound, n'ihi ya, egosighi na ọnụ ọgụgụ. Dị ka a na-ahụ site na foto 7, mgbe a na-anwale ule ahụ n'okpuru mmiri ọkụ saturation, mgbọ ike ọnwụ dị njọ, na ike ịmịnye ihe nlele ahụ mgbe ọgwụgwọ okpomọkụ na-abawanye.

Ọgụgụ 6 bụ eserese eserese nke mpaghara ntule nke mgbọ ahụ mere ọsọ na oghere mmebi oyi akwa CFRP (akara ntụ ntụ na-egosi akụkụ nke Figure 4), enwere ike ịhụ ọnụ ọgụgụ zuru oke (4), (5), (6): (1) na mmụba nke mmetụta ọsọ, CFRP oyi akwa oyi akwa mebiri oghere ntule ebe na-abawanye; (3) mgbe mmetụta ọsọ bụ banyere 45 m / s, ntule ebe nke mmebi nke laminated efere mgbe mmiri okpomọkụ ọgwụgwọ bụ nnọọ ibu karịa ntule ebe nke laminated efere mebiri oghere na akọrọ ụlọ okpomọkụ ala. Wet thermal saturation sample mebiri l-oghere ntule mpaghara mụbara site na 85. 1% na na a ujo ọsọ nke banyere 68 m / s, na laminated efere na a mmiri na thermal saturation steeti mụbara site 18. 10%, absorption uru (Ọnụ ọgụgụ 5) mụbara site 15. 65%; Na mmetụta ọsọ nke banyere 88 m / s, na laminated efere na mmiri na thermal saturation steeti belatara site 9. 25%, absorption uru ka na-abawanye site 12. 45%.

Dabere na nsonaazụ nyocha nke Yucheng Zhong na ngwaahịa ndị ọzọ, nnabata mmiri nke carbon fiber na-eme ka ihe mejupụtara ya na-eme ka njedebe na-agbanwe agbanwe na nguzogide mmetụta nke efere laminate ahụ, ma na-ejikọta akụkụ a tụrụ anya nke oghere mebiri emebi nke ụlọ akọrọ na ụdị saturation mmiri na-ekpo ọkụ n'ime akwụkwọ a (Ọnọdụ 4) na njikọ ahụ na-agba ọsọ na eserese gray. mpaghara nke oghere mmebi oyi akwa CFRP, na mmebi oyi akwa nke CFRP na-ejikọta osisi nwere ike iji tụnyere mgbe mmetụta ọsọ dị otu na ala. Ebe mmebi nke ihe nleba anya saturation na-ekpo ọkụ dị oke ibu. Nke a bụ n'ihi na mmiri ọkụ ọgwụgwọ na-eme ka CFRP oyi akwa substrate plasticization, ike ọgwụgwụ eriri na substrate interface na interlayer arụmọrụ, na mmetụta, mmiri okpomọkụ saturation ọnọdụ nke ụdị Layered mmebi mgbasa, nkezi nke mmebi mụbara. Dabere na Wu Yixuan na ndị ọzọ nnwale mara na mmetụta ike na vetikal paving direction tumadi etinye obi gị dum site resin mkpụrụ, mgbe ahụ, plasticization nke mkpụrụ na-eme ka mmiri na-ekpo ọkụ saturation ụdị banye ọzọ ume n'oge mmetụta usoro, mma mmetụta eguzogide, na enwekwu ntule ebe nke oghere mebiri; CFRP laminate mebiri emebibeghị nke ọma, mmetụta ahụ agwụla, ya mere, mgbe mmetụta ọsọ ọsọ dị elu, ọgwụgwọ mmiri na-ekpo ọkụ na mpaghara CFRP laminate mebiri emebi adịghịzi njọ, ma n'ihi plasticization nke resin substrate, ikike absorption ka na-abawanye.

4 Nkwubi okwu

(1) Site na mmụba nke mmetụta ọsọ ọsọ, atumatu mpaghara nke mmebi oghere nke carbon fiber mesikwuru epoxy resin composite (CFRP) laminate na-abawanye, na uto ọnụego nke mmebi 孑L oghere na sample na akọrọ ụlọ okpomọkụ dị elu karịa na n'okpuru udu mmiri saturation. Nnukwu: (2) Mgbe mmetụta ọsọ ọsọ dị 45 m / s, ebe mmebi mmebi nke CFRP laminate na mmiri okpomọkụ saturation steeti na-abawanye site na 85. 11%, mgbe mmetụta ọsọ dị 68 m / s, mmebi nhụsianya nke CFRP laminate na mmiri okpomọkụ saturation steeti na-abawanye site na 18% okpomọkụ nke ala akọrọ. 10%, mmetụta ọsọ bụ 86m / s. Ebe nleba anya mmebi cFRP juru mmiri juru na-ebelata site na 9.9% ma e jiri ya tụnyere ụlọ kpọrọ nkụ cFRP laminate. 25%; (3) Mgbe cFRP laminate na-emetụta gburugburu ebe obibi na-ekpo ọkụ na iru mmiri, arụ ọrụ interlayer nke laminate na-ebelata, na-eme ka mgbasawanye nke mpaghara delamination.

Oge nzipu: Jun-24-2019