1 Nhanganyaya

Carbon fiber reinforced epoxy composite (CFRP) ine zvakawanda zvakanaka senge yakaderera density, yakakwirira chaiyo kusimba, yakanyanya kuomarara, kuramba kuneta, corrosion resistance uye yakanaka mechanical properties. Inoshandiswa zvakanyanya muaerospace uye zvimwe zvimiro zvine hukasha, kupisa kwakanyorova uye kukanganisa. Pesvedzero yezvakatipoteredza zvinhu pazvinhu zviri kuwedzera kuoneka. Mumakore achangopfuura, nyanzvi dzepamba nedzekunze dzakaita nhamba huru yezvidzidzo pamhedzisiro yekupisa uye hunyoro nharaunda paCFRP macomposites [1] uye kukanganisa kwekukanganisa kweCFRP macomposites. Chidzidzo chacho chakawana kuti pesvedzero yenzvimbo inopisa uye ine mwando paCFRP macomposites inosanganisira plasticization yematrix [2, kutsemuka [31 uye kushaya simba faibha-matrix interface zvimiro [2'3'5], CFRP inoumbwa inokotama nekuwedzera kunyorova kupisa kupisa nguva) Iyo michina yekuita [2, lead uye interlaminar shear zvimiro [2, 13 uye static '6' nhanho]. Woldesenbet et al. [8,9] akadzidza maitiro emagetsi ezvikombisi pahuwandu hwekunetsekana mushure mekunyorova kwekupisa kurapwa, uye akawana kuti nzvimbo inopisa uye ine unyoro yakavandudza simba rekuita remakompositi. Zvinoratidzwa kuti kunyura kwehunyoro hwezvinhu zvinosanganiswa kunogona kuvandudza maitiro emuchina wezvinhu pasi pemamwe mamiriro ezvinhu, ayo akasiyana zvakanyanya nemhedzisiro yekuedzwa pasi pequasi-static mamiriro. Irizvino basa guru rekutsvagisa mhedzisiro yekupisa kwakanyorova (kusanganisira kunyudzwa kwemvura) pane yakaderera velocity kukanganisa zvimiro zvefiber reinforced resin matrix composite. Pan Wenge et al [10] vakadzidza kumanikidzana kweviri-dimensional yakarukwa fiberglass / epoxy composite laminates mushure mekudzika-kumhanya kukanganiswa patembiricha yekamuri uye pasi pekupisa uye hunyoro mamiriro (65 °C kunyudzwa mumvura). 4. Iyo laminate pasi penzvimbo inopisa uye ine unyoro inowanikwa mushure mekuderera kwekuvhunduka. The compression performance yakanyanya kuderedzwa. Karasek et al. [1] akadzidza mhedzisiro yekunyorova uye tembiricha pakukanganisa kwegraphite/epoxy composite, uye akaiwana munzvimbo yakaderera tembiricha uye kamuri tembiricha. Humidity haina mhedzisiro pane yekutanga simba uye simba kutorwa kwekukuvara. Yucheng zhong et al [12,13] vakaita bvunzo yakaderera-yekumhanya pamisanganiswa laminates mushure mekunyorova kwekupisa kurapwa. Izvo zvinogumiswa kuti nzvimbo inopisa uye ine hunyoro inoderedza zvakanyanya kukanganisa kukanganisa kwelaminate. Kuvandudza kukanganisa kupikisa kwema laminates. Krystyna et al. [14] akadzidza kuderera-kumhanya kwearamid-girazi fiber / epoxy composite mushure mekunyorova kwekupisa (70 °C kunyudzwa mumvura), uye akawana nzvimbo diki yekukuvadza mushure mekunyorova kwekupisa. Izvi zvinokonzeresa kukuvara kwe delamination mukati memuenzaniso, iyo inotora simba rakawanda panguva yekukanganisa uye inodzivirira kuumbwa kwe delamination. Zvinogona kuonekwa kubva pane zviri pamusoro kuti pesvedzero yenzvimbo yakanyorova yekupisa pane kukanganisa kukanganisa kwezvinhu zvinosanganiswa ine kusimudzira mhedzisiro uye kushaya simba. Naizvozvo, kumwe kutsvagisa nekusimbisa kunodiwa. Nezvekukanganisa, Mei Zhiyuan et al [15] vakaronga uye vakagadzira nhanho mbiri (kugera kupinza uye kupfuurira kupinza) kupinza simba rekuongorora modhi yefiber-yakasimbiswa composite laminates pasi pekumhanya-mhanya. Guiping Zhao et al. [16] yakaita marudzi matatu ekumhanya kwakasiyana (zvisingasviki, zvakaenzana uye zvakakura kudarika ballistic limit speed) pakukanganisa kwekuita uye kukuvara kwemuenzaniso mushure memhando nhatu dzelaminates, asi hazvina kubatanidza kukanganisa kwemhepo yakanyorova yekupisa pane kukanganisa kukanganisa. . Kubva pane zvinyorwa zviri pamusoro apa, tsvakurudzo yakabatana pamusoro pekugadzirisa kwemvura uye inopisa nharaunda pane fiber reinforced composite laminates haisati yaongororwa zvakare. Mupepa iri, kukanganiswa kwemaitiro ekunyorova kupisa kwakazara kabhoni fiber / epoxy composite laminates pasi pe70 °C yemvura yekugezesa mamiriro akadzidzwa. Mhedzisiro yenzvimbo inopisa uye ine hunyoro pane kukanganisa kutadza maitiro ekompositi yakaongororwa nekuenzanisa neyakaoma kamuri tembiricha samples. Mukuedza, maCFRP laminates akabatwa paCFRP laminates pa45 m/s, 68 m/s uye 86 m/s. Velocity isati yasvika uye mushure mekukanganisa kwakayerwa. Kupesvedzera kwenzvimbo inopisa uye ine mwando pakuita kwesimba rekunyudza kwema laminates kwakaongororwa. Ultrasonic c-scan yakashandiswa kuona kukanganisa kwemukati kwelaminate, uye simba rekukanganisa velocity panzvimbo yakaputsika yakaongororwa. Iyo scanning electron maikorosikopu uye iyo yekupedzisira-yakadzika-yakadzika matatu-dimensional microscopic system yakashandiswa kuona mesoscopic maitiro ekukuvadzwa kwemuenzaniso, uye kukuvadzwa kwesample kwakaongororwa nemhepo inopisa nharaunda. Kukanganisa kwezvimiro.

2 Kuedza zvinhu uye nzira

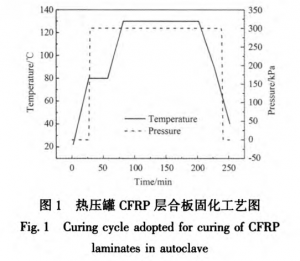

2. 1 Zvinyorwa uye kugadzirira

Carbon fiber epoxy resin (T300/EMl 12) composite material, pre-immersion yakapiwa naJiangsu Hengshen Co., Ltd., single-layer pre-immersion thick of 0. 137 mm ine fiber volume chikamu chikamu che66%. Iyo laminate panel yakaiswa pasi peiyo layer. , saizi 115mm x 115mln. Iyo yekuumba maitiro e-hot-press tank inoshandiswa. Chiratidzo chekugadzirisa chirongwa chakagadzirirwa nechirongwa chinoratidzwa mumufananidzo 1. Kutanga kusimudza nzvimbo yekugara kubva muimba yekupisa kusvika ku80 oC pamwero wekupisa we 1 kusvika 3 oC / min, zvino ramba uchidziya kwemaminitsi makumi matatu, kupisa kusvika ku130 oC pakupisa kwel13 oC / min, ramba uchidziya pa120 min, kuderedza kusvika ku60.0C panguva yekutonhora nguva dzose, uye wozobvisa kumanikidzwa uye kusunungura, uye kusunungura.

2. 2 Wet kupisa kurapwa

Mushure mekugadzirwa kwemuenzaniso, sampu yakanyorova-kupisa-yakagadziriswa zvinoenderana neyakatsanangurwa HB 7401-96.171 "Resin-based composite composite layer yakanyorova inopisa nharaunda mwando yekuyedza nzira". Kutanga, mufananidzo wacho unoiswa mukamuri yekuomesera ye thermostatic pa70 degrees C kuti iome. Kuyera nguva dzose uchishandisa zviyero kusvikira kurasikirwa kwehutano kwemuenzaniso kwakadzikama pasina kupfuura 0. 02%, kukosha kwakanyorwa panguva ino ndeye Engineering Dry Mass G. Mushure mekuoma, muenzaniso unoiswa mu 70 degrees C yemvura yekunyorova kwekupisa. Zvinoenderana nekutsanangurwa kweHB 7401. Iyo nzira inotsanangurwa muna 96 "inoyera kunaka kwemuenzaniso zuva rega rega, yakanyorwa seGi, uye inonyora shanduko yekutorwa kwemwando Mi. Iyo yekunyorovesa kunyura kweiyo CFRP laminate specimen ndeye:

Iyo fomula yakatsanangurwa: Mi ndiko kunyura kwehunyoro hwemuenzaniso, Gi ndiyo mhando mushure mekunge sampu yatora hunyoro, g, enda ndiyo yakaoma mamiriro eiyo specimen engineering.

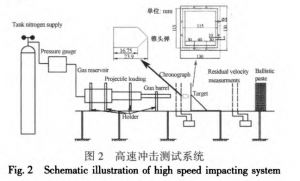

2. 3 Impact Miedzo

Iyo yekumhanyisa-kumhanyisa kuyedza paCFRP laminate yakaitwa pamhepo inomhanya-mhanya ine dhayamita ye15 mm. Yepamusoro-yekumhanyisa maitiro ekuyedza mudziyo (ona Mufananidzo 2) inosanganisira pfuti yemhepo inomhanya, laser yekuyeresa kumhanya isati yasvika uye mushure mekubata, bullet body, specimen installation fixture (kona yepamusoro yekurudyi yeFigure 2), uye bullet body security recovery device. Iyo bullet body is a cone-headed cylindrical bullet (Mufananidzo 2), uye vhoriyamu yebhoti ndeye 24. 32 g nehupamhi hwe 14. 32 mm; kumhanya kwesimba ndeye 45 m/s (impact simba 46 J), 68 m/s (impact simba 70 J), 86 m/s (impact simba 90 J) kukanganisa.

2. 4 Kukanganisa kuona kwezvienzaniso

Mushure mekukanganiswa nekukanganiswa, iyo kabhoni fiber color epoxy composite composite laminate layer edgout plate inoshandiswa kuona kukuvara kwemukati kweCFRP laminate plate, uye nzvimbo yekufungidzira yenzvimbo yakakuvadzwa inoyerwa nesoftware yekuongorora UTwim, uye iwo akadzama maficha ekuparadza-chikamu-chikamu anocherechedzwa nekuvheneka maelectronic microscope uye ultra-3p yemunda we ultra-de.

3 Migumisiro nehurukuro

3. 1 Inofananidzira maitiro ekutorwa kwemwando

Huwandu hwe37. 7 d, avhareji yekunyura hunyoro hunyoro ndeye 1. 780%, ine chiyero chekupararira che6. 183x10. 7llnl2/s. Iko kunyura kwekunyorova kweiyo CFRP laminate specimen inoratidzwa muMufananidzo 3. Sezvingaonekwa kubva kuMufananidzo 3, kukura kwekutanga kwekukura kwekunyura kwemuenzaniso kune mutsara, mushure memutsara wemutsara, kuwedzera kwekukura kwekunyorova kunotanga kuderera, kusvika kune imwe nzvimbo yakadzikama mushure uye kusvika kune imwe nguva yekunyorova kwe23. Nokudaro, kunyura kwemvura yemuenzaniso kunopindirana nematanho maviri ekunyorovesa unyoro: danho rekutanga rekunyorovesa hunyoro hunokonzerwa nekubatana kwekuita kwekushisa uye kunyorova, unyoro kuburikidza nechinhu chacho pachacho chine pores, maburi, kuputika uye zvimwe zvikanganiso zvakapararira mukati mechinhu; Kupararira kwemvura kunononoka uye zvishoma nezvishoma kunosvika pakuzara panguva ino.

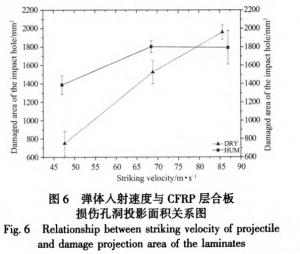

3. Izvo zvinoratidzika zvinoparadza maitiro e2-layer laminate board

Impact kumhanya ye86 m/s kana specimen yemberi, kumashure kweinooneka dhizaini mepu, neyakaoma yekamuri tembiricha sampu, yakanyorova inopisa saturation saturation yepamberi yekuparadza chimiro yakafanana, zvienzaniso zviviri mukukanganisa, nekuda kwekutsemuka kwenheyo, kuparadzwa kwayo pamwe nechikamu chekutanga chefiber kune kumwe kutsvedza. Izvi zvinoita kuti kumberi kupe chimiro che elliptical kana rectangular, uye kunze kwekukwanisa kuona kutsemuka mu substrate, mafiibhi anogona kuonekwa achiputsika. Neyakaoma kamuri tembiricha sampuli, yakanyorova inopisa saturation sampu kuseri kwekuparadzwa kwechimiro kunogona kuoneka kuti kumashure pamwe negwara rekukanganisa kune imwe bulge, uye inopa kutsemuka kwakaumbwa. Zviri pachena kuti fiber fracture, base cracking uye interlayer fracture (layering) maitiro matatu ekuparadza, chikamu chekupedzisira chefiber chinosimudzwa asi chisina kuputsika, kungoisa chete uye fiber / base cracking. Iyo fiber fracture yakasiyanawo, sezvinogona kuonekwa kubva pakuenzanisa kwekukuvadzwa kwepamberi uye kumashure. Iko kumberi kunokonzera kuputsika kwefiber uye substrate nekuda kwekumanikidza uye kugera. Kumashure kunokonzerwa nekutambanudza kwakakonzera kuti fiber iparadze uye inoisa iyo substrate. Mufananidzo 4 inotyisa kumhanya kwe 45 m/s, 68 m/s, 86 m/s apo special kukuvara kwemukati C scan. Nzvimbo inoratidzwa neinoda kutenderera l grey mutsara pakati pechifananidzo ndiyo inofungidzirwa nzvimbo yegomba rekukuvadza. Mutsara mutema kumusoro uye pasi pega yega chati diki inoratidza nzvimbo yekuseri kubhenda nzvimbo yemuenzaniso. Nzvimbo yakanyorwa mumutsara muchena pamufananidzo (b) (d) (f) ndiko kukanganisa kwemukati kwemuenzaniso pamuganhu. Girafu inoratidza kuti simba rekuita rinowedzera sezvo kukurumidza kwekukanganisa kunowedzera. Iyo laminated plate inokwanisa kutora simba rakawanda panguva yekukanganisa (ona Mufananidzo 6 kune chaiyo kukosha), zvichikonzera kuwedzera kwenzvimbo yelaminate kukuvara fungidziro: nekuenzanisa iyo yakaoma kamuri tembiricha sampu nemufananidzo wekunyorova kunopisa kupisa saturation specimen, zvinogona kuoneka kuti kune mukati kukuvadzwa (muchena mutsara) wemuenzaniso wakagadzirwa padivi pemuganhu mukunyorova-kupisa kwekufungidzira kunoenderana nemamiriro ekunze. Ipurasitiki ye substrate muplate ye laminate uye kupera simba kwe-fiber-base interface inoita kuti muganho uve nemigumisiro paplate ye laminate panguva yekushanda. Maererano nemufananidzo, nzvimbo yekuchera kumashure (mutsara wakasviba) wemuenzaniso mumamiriro akaoma haisi yakasiyana zvikuru nekunyorova kwemhepo inopisa.

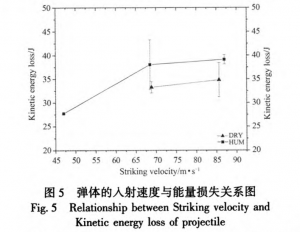

3. Izvo zvakadzama zvinoparadza zvinhu zve 3-layer panel

Iyo muchinjika-chikamu kukuvara inoratidzira mepu yeCFRP layer yakabatana ndiro, yakatorwa neiyo yakadzika-yakadzika 3D microsystem uye scanning erekitironi girazi, ine kumhanya kwemakumi mana neshanu m/s, yakaoma uye yakanyorova uye inopisa, inoratidza kuti kukuvadzwa kwemuenzaniso mumatunhu ese ari maviri kunosanganisira nzira nhatu dzekuparadza: kutsemuka kwefayibha, kuputika kwepasi uye kutsemuka kwepakati. Asi hwaro hwezvienzaniso zviviri zvakatsemuka zvakasiyana. Kuputika kwe substrate mumamiriro akaoma kunoputika pakubatana pakati pefiber uye substrate. Nekudaro, kuputika kweiyo substrate mushure mekunyorova kupisa kurapwa kunoperekedzwa nezvimedu zve substrate zvinowira kunze. Wold-esenbet uye zvimwe zvinhu munzvimbo inonyorova uye inopisa yekukanganisa kuita kwechimiro chechimiro uye faibha substrate interface kushatiswa kwakabatana kwakatemwa, munzvimbo inopisa inopisa, CFRP layer plate mune resin base chiitiko kunyudzwa kweimwe huwandu hwemvura, inoyerera mvura ichaita kuti resin substrate inyunguduke. Carbon fiber haina kunyura, saka panofanira kuve nekunyorova kuwedzera pakati pezviviri, mutsauko uyu unonetesa kuwirirana pakati pe substrate uye fiber, inoderedza simba reiyo substrate. Kana yaiswa pasi pemutoro wekukanganisa, zvimedu zve substrate zvinodonhedzwa zviri nyore, zvichikonzera mutsauko kubva kune yakaoma kamuri tembiricha yekukuvadza kukuvara interface. Kubva pane yakadzama chimiro cheyakaongororwa girazi remagetsi, zvinogona kuoneka kuti kuputika kweiyo yakanyorova uye inopisa post-base body inonyanya kusununguka kuputika kweiyo press break, nepo kuputika kusati kwapisa kupisa kunonyanya brittle, uye yakatwasuka shear inotsemuka pakati pezvikamu zviri pachena. Kubva pane optical microscope mumufananidzo, zvinogona kuonekwa kuti mafomu ekuparadza akasiyana mumatambudziko maviri, uye mamiriro akaoma ari per-inter-cutting kuparadzwa. Kucheka kuparadzwa kunyanya, mushure mekupisa kwekunyorova kwechimiro chekuparadza kunoperekedzwa nekuparadza kwakakura kwakapetwa, chikamu chekuparadzwa kwakapetwa kwakawedzera. Inogona kuonekwa kubva pakona yekuparadzwa kwemaitiro uye maitiro ekutora simba. Mei Zhiyuan akaisa mberi nhanho mbiri dzekupinda kweprojekiti: nhanho yekucheka uye inoenderera nhanho yekupinda. Iyo A nharaunda mune yakanyorova inopisa sampu ndiyo shear intrusion nhanho kuparadzwa, kunyanya nekuti mukukanganisa maitiro, iyo layering ndiro inotsikirirwa uye sheared kuumbwa kwekuparadza deformation, b nzvimbo ndiyo inoenderera yekupinda nhanho kuparadzwa. Iyi nhanho inonyanya kukonzerwa nekuderedzwa kweiyo bullet body intrusion speed pasi pekuita kwekutambanudza kushungurudza chikamu che fibrous layer, uye simba rinonyanya kushandurwa kuva fiber stretch strain strain simba uye interlayer fracture simba (l 51), kuitira kuti fiber break el uye yapfuura fiber break haisi mumutsara wakatwasuka. Mumuenzaniso wakaoma, chiitiko ichi hachisi pachena, uye kukuvadzwa kweplate kwakanyanyisa, chidimbu cheplate chine nyika inoputika. 3. 4 Absorption simba uye damagehole projection area analysis Mufananidzo 5 unoratidza hukama huri pakati pekushisa kwekamuri yakaoma uye kunyorova kwekupisa kwekupisa kwekukurumidza kwekutanga uye kurasikirwa kwesimba kwemuviri, pachiitiko chinokurumidza kusvika 45 m / s, kupisa kwekamuri yakaoma yebhoti yose inodzoka, saka haina kuratidzwa mumufananidzo. Sezvinogona kuonekwa kubva kuMufananidzo 7, apo muedzo unoedzwa pasi pemvura inopisa yekupisa, iyo bullet simba kurasikirwa kwakakomba, uye kusveta simba remuenzaniso mushure mekunyorova kwekupisa kunowedzera.

Mufananidzo 6 igirafu dhayagiramu yenzvimbo yefungidziro yenzvimbo yekumhanyisa chiitiko chemuviri uye CFRP layer yekukuvara gomba (iyo grey line inotaridza chikamu cheMufananidzo 4), yakazara nhamba (4), (5), (6) inogona kuoneka: (1) nekuwedzera kwekukanganisa kukurumidza, iyo CFRP layer yekukuvara kwegomba fungidziro nzvimbo inowedzera munzvimbo yakakura; kupisa kunopisa; (3) kana iyo yekumhanyisa kumhanya inosvika 45 m / s, iyo nzvimbo yekufungidzira yegomba relaminate plate mushure mekunyorova kupisa kurapwa kwakakura kupfuura nzvimbo yekufungidzira yegomba rakakuvadzwa ndiro munzvimbo yakaoma tembiricha yekamuri. Wet thermal saturation sampuli kukuvadzwa l-gomba fungidziro nzvimbo yakawedzera ne 85. 1% uye pakuvhunduka kumhanya anenge 68 m / s, iyo laminated ndiro munzvimbo yakanyorova uye yekupisa yekupisa yakawedzera ne 18. 10%, kukosha kwekutora (Mufananidzo 5) yakawedzera ne15. 65%; Pakumhanyisa kumhanya kweanenge 88 m / s, iyo laminated ndiro munzvimbo yakanyorova uye yekupisa yekupisa yakaderedzwa ne9. 25%, kukosha kwekunyura kuchiri kuwedzera ne12. 45%.

Zvichienderana nemhedzisiro yekutsvagisa yeYucheng Zhong nezvimwe zvigadzirwa, kunyura kwekabhoni fiber-yakasimbiswa inoumbwa zvinhu inovandudza muganho wakasimba uye kukanganiswa kwekudzivirira kweplateti yelaminate, uye inosanganisa nzvimbo inofungidzirwa yegomba rekukuvadza kwekamuri yakaoma tembiricha yemhando uye yekunyorova inopisa saturation specimen mubepa rino (Mufananidzo 4 mumutsara we grey mutsara weiyo dhiyabhorosi mutsara weiyo dhizaini mutsara CFRP layer yekukuvara gomba, uye iyo yakaturikidzana kukuvara kweCFRP layer yekujoinha bhodhi inogona kuenzaniswa kana kumhanya kwekuita kwakafanana uye kwakaderera. Iyo damagehole nzvimbo ye wet hot saturation specimen yakakura. Izvi zvinokonzerwa nekunyorova kwekupisa kurapwa kunoita iyo CFRP layer substrate plasticization, kushaya simba faibha uye substrate interface uye interlayer kuita, mukukanganisa, kunyorova kwekupisa kwemamiriro eiyo specimen akaturikidzana kukuvara kwekuwedzera, chikamu chekukuvara chakawedzera. Zvichienderana neWu Yixuan uye zvimwe zviedzo zvinoziva kuti simba rekuita mu vertical paving direction rinonyanya kunyudzwa neresin substrate, ipapo plasticization ye substrate inoita kuti mvura uye inopisa saturation specimen itore simba rakawanda panguva yekukanganisa, inovandudza kupikisa, uye inowedzera nzvimbo yekufungidzira yegomba rekukuvadza; CFRP laminate kukuvadzwa hakusati kwawedzerwa zvizere, kukanganisa kwapera, saka kana kumhanya kwekuita kwakakwira, iyo yekunyorova yekupisa kurapwa panzvimbo yeCFRP laminate kukuvara kwenzvimbo haichanyanya kukomba, asi nekuda kweplasticization ye substrate resin, simba rekunyura richiri kuwedzera.

4 Mhedziso

(1) Nekuwedzera kwekukanganisa kukurumidza, iyo inofungidzirwa nzvimbo yegomba rekukuvadzwa kwekabhoni fiber yakasimbisa epoxy resin composite (CFRP) laminate inowedzera, uye kukura kwekukura kwegomba 孑L musampurero pakuoma kwekamuri tembiricha yakakwira kupfuura iyo iri pasi pekupisa kwekunyorova. Yakakura: (2) Kana kukanganiswa kwemhepo kuri 45 m / s, nzvimbo yekukuvadza yeCFRP laminate munzvimbo yakanyorova yekupisa inowedzerwa ne85. 11%, kana kukanganisa kwevelocity iri 68 m / s, nzvimbo yekukuvara kweCFRP laminate munzvimbo yekunyorova yekupisa inowedzerwa ne18% tembiricha yeCFRP mukamuri yakaoma. 10%, iyo yekumhanyisa kumhanya ndeye 86m / s. Iyo yakanyoroveswa-yakazara cFRP laminate kukuvara kwenzvimbo inoderedzwa ne9.9% kana ichienzaniswa neyakaoma yekamuri tembiricha cFRP laminate. 25%; (3) Mushure mokunge cFRP laminate ichibatwa nemamiriro ekunze anopisa uye ane hunyoro, kushanda kwe interlayer ye laminate kunoderedzwa, zvichiita kuti nzvimbo ye delamination iwedzere.

Nguva yekutumira: Jun-24-2019