1 Kev Taw Qhia

Carbon fiber reinforced epoxy composite (CFRP) muaj ntau yam zoo xws li tsis tshua muaj ceev, muaj zog tshwj xeeb, siab nruj nruj, qaug zog tsis kam, corrosion kuj thiab zoo txhua yam khoom. Nws yog dav siv nyob rau hauv aerospace thiab lwm yam ib puag ncig hnyav qauv, damp cua sov thiab cuam tshuam. Kev cuam tshuam ntawm ib puag ncig yam ntawm cov ntaub ntawv yog nce pom tseeb. Nyob rau hauv xyoo tas los no, cov kws tshawb fawb hauv tsev thiab txawv teb chaws tau ua ntau qhov kev tshawb fawb txog qhov cuam tshuam ntawm qhov kub thiab av noo ntawm CFRP cov khoom sib xyaw [1] thiab qhov cuam tshuam ntawm kev cuam tshuam ntawm CFRP cov khoom sib xyaw. Txoj kev tshawb nrhiav pom tias qhov cuam tshuam ntawm qhov kub thiab av noo ntawm CFRP composites suav nrog plasticization ntawm matrix [2, cracking [31 thiab tsis muaj zog fiber-matrix interface zog [2'3'5], CFRP composite dabtsi yog khoov nrog nce ntub dej kub kho lub sij hawm) Cov khoom siv ntawm kev ua tau zoo [2, lead thiab interlaminar shear zog [10, 1 ward ' thiab 3 static ward zog . Woldesenbet et al. [8,9] tau kawm txog qhov cuam tshuam ntawm cov khoom sib xyaw ntawm cov khoom sib xyaw ntawm cov kab mob siab tom qab kev kho cua sov ntub, thiab tau txais tias qhov kub thiab av noo ib puag ncig txhim kho qhov cuam tshuam lub zog ntawm cov khoom sib xyaw. Nws tau tshaj tawm tias qhov nqus dej ntawm cov khoom sib xyaw tuaj yeem txhim kho qhov cuam tshuam ntawm cov khoom siv hauv cov khoom siv hauv qee qhov xwm txheej, uas txawv heev ntawm cov txiaj ntsig kev sim hauv cov xwm txheej quasi-static. Kev tshawb fawb tseem ceeb tam sim no yog qhov cuam tshuam ntawm cov cua sov (xws li dej immersion) ntawm qhov tsis tshua muaj kev cuam tshuam cov khoom ntawm fiber reinforced resin matrix composites. Pan Wenge et al [10] tau kawm txog compression zog ntawm ob-dimensional woven fiberglass / epoxy composite laminates tom qab qis-ceev cuam tshuam ntawm chav tsev kub thiab nyob rau hauv kub thiab ntub dej (65 ° C dej immersion). 4. Lub laminate nyob rau hauv qhov kub thiab ntub ib puag ncig yog tau tom qab tsis tshua muaj kev poob siab. Lub compression kev ua tau zoo yog txo qis. Karasek et al. [1] tau kawm txog qhov cuam tshuam ntawm cov av noo thiab qhov kub thiab txias ntawm qhov cuam tshuam ntawm graphite / epoxy composites, thiab tau txais lawv nyob rau hauv qhov kub thiab txias qhov chaw. Cov av noo muaj me ntsis cuam tshuam rau thawj lub zog thiab lub zog nqus ntawm qhov kev puas tsuaj. Yucheng zhong et al [12,13] tau ua qhov kev ntsuas qis-ceev ntawm cov laminates sib xyaw tom qab ntub dej kub kho. Nws tau xaus lus tias qhov kub thiab av noo ib puag ncig txo qhov cuam tshuam kev puas tsuaj ntawm laminate. Txhim kho qhov cuam tshuam tsis zoo ntawm laminates. Krystyna et al. [14] tau kawm txog qhov cuam tshuam qis qis ntawm aramid-iav fiber ntau / epoxy composite tom qab kev kho cua sov ntub dej (70 ° C dej immersion), thiab tau txais qhov cuam tshuam me me tom qab kev kho cua sov ntub. Qhov no ua rau delamination puas hauv cov qauv, uas absorbs ntau zog thaum muaj kev cuam tshuam thiab inhibits tsim delamination. Nws tuaj yeem pom los ntawm cov saum toj no hais tias qhov kev cuam tshuam ntawm cov cua sov ib puag ncig ntawm qhov cuam tshuam kev puas tsuaj ntawm cov ntaub ntawv sib xyaw muaj kev txhawb nqa thiab ua kom tsis muaj zog. Yog li ntawd, xav tau kev tshawb fawb thiab kev txheeb xyuas ntxiv. Hais txog kev cuam tshuam, Mei Zhiyuan li al [15] tau thov thiab tsim ob-theem (shear penetration thiab nruam nkag) nkag mus rau hauv lub zog tsom xam qauv ntawm fiber-reinforced composite laminates nyob rau hauv high-ceev cuam tshuam. Guiping Zhao et al. [16] tau ua peb hom kev sib txawv ntawm qhov sib txawv (tsawg dua, sib npaug thiab ntau dua qhov kev txwv tsis pub tshaj qhov nrawm) ntawm kev cuam tshuam kev ua tau zoo thiab kev puas tsuaj ntawm cov qauv tom qab peb hom laminates, tab sis tsis cuam tshuam rau qhov cuam tshuam ntawm cov cua sov ib puag ncig ntawm kev puas tsuaj. . Raws li cov ntaub ntawv saum toj no, cov kev tshawb fawb txog kev cuam tshuam ntawm qhov chaw ntub dej thiab kub ntawm cov fiber reinforced composite laminates tseem tsis tau tshawb nrhiav ntxiv. Nyob rau hauv daim ntawv no, qhov cuam tshuam kev puas tsuaj cov yam ntxwv ntawm ntub cua sov saturated carbon fiber / epoxy composite laminates nyob rau hauv 70 ° C dej da dej tej yam kev mob tau kawm. Qhov cuam tshuam ntawm qhov kub thiab noo ib puag ncig ntawm qhov cuam tshuam tsis ua haujlwm cov yam ntxwv ntawm cov khoom sib xyaw tau txheeb xyuas los ntawm kev sib piv nrog cov qauv hauv chav qhuav qhuav. Hauv kev sim, CFRP laminates tau cuam tshuam rau CFRP laminates ntawm 45 m / s, 68 m / s thiab 86 m / s. Qhov nrawm ua ntej thiab tom qab qhov cuam tshuam raug ntsuas. Kev cuam tshuam ntawm qhov kub thiab av noo ib puag ncig ntawm lub zog nqus kev ua haujlwm ntawm laminates tau txheeb xyuas. Ultrasonic c-scan tau siv los txheeb xyuas qhov kev puas tsuaj sab hauv ntawm lub laminate, thiab qhov cuam tshuam ntawm qhov cuam tshuam nrawm ntawm thaj chaw tawg tau raug tshuaj xyuas. Lub tshuab ntsuas hluav taws xob ntsuas hluav taws xob thiab lub tshuab ntsuas qhov tob tob-qhov tob peb-dimensional microscopic tau siv los soj ntsuam cov yam ntxwv mesoscopic ntawm cov qauv kev puas tsuaj, thiab qhov kev puas tsuaj ntawm cov qauv raug tshuaj xyuas los ntawm qhov chaw sov sov. Qhov cuam tshuam ntawm cov yam ntxwv.

2 Cov ntaub ntawv sim thiab cov txheej txheem

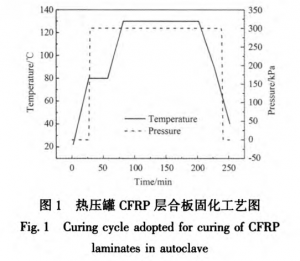

2.1 Cov khoom siv thiab kev npaj

Carbon fiber ntau epoxy resin (T300 / EML 12) cov khoom sib xyaw, ua ntej immersion muab los ntawm Jiangsu Hengshen Co., Ltd., ib txheej ua ntej immersion thickness ntawm 0. 137 hli nrog fiber ntau feem ntawm 66%. Lub vaj huam sib luag laminate yog muab tso rau hauv pem teb ntawm txheej. , Luas 115 x 115 mm. Cov txheej txheem tsim ntawm kub xovxwm tank yog siv. Daim duab qhia kev kho cov txheej txheem npaj los ntawm cov txheej txheem yog pom hauv daim duab 1. Thawj tsa lub tsev nyob hauv chav tsev kub txog 80 oC ntawm qhov cua sov ntawm 1 txog 3 oC / min, tom qab ntawd ua kom sov li 30 min, cua sov rau 130 oC ntawm qhov cua sov ntawm l13 oC / min, kom sov ntawm 120 min, txo kom sov li 120 min.0C ntawm qhov ntsuas kub tsis tu ncua, thiab tom qab ntawd tshem tawm lub siab thiab tso tawm, thiab tso tawm.

2. 2 Kev kho cua sov ntub dej

Tom qab kev npaj cov qauv, cov qauv tau ntub-kub-kho raws li qhov tshwj xeeb HB 7401-96.171 "Resin-based composite txheej txheej ntub dej kub ib puag ncig noo noo kev sim txoj kev". Ua ntej, cov qauv yog muab tso rau hauv lub thermostatic drying chamber ntawm 70 degrees C kom qhuav. Kev ntsuas tsis tu ncua siv cov khoom sib npaug kom txog rau thaum qhov tsis zoo ntawm cov qauv yog qhov ruaj khov ntawm qhov tsis muaj ntau tshaj 0. 02%, tus nqi sau tseg rau lub sijhawm no yog Engineering Qhuav Mass G. Tom qab ziab, cov qauv muab tso rau hauv 70 degrees C ntawm dej rau kev kho cua sov ntub. Raws li qhov tshwj xeeb HB 7401. Cov txheej txheem tau teev nyob rau hauv 96 " ntsuas qhov zoo ntawm cov qauv txhua hnub, kaw raws li Gi, thiab sau cov kev hloov ntawm noo noo nqus Mi. Cov dej noo nqus qhia ntawm CFRP laminate specimen yog:

Cov mis yog cov ncauj lus kom ntxaws: Mi yog qhov nqus dej noo ntawm cov qauv, Gi yog qhov zoo tom qab tus qauv absorbs ya raws, g, mus yog lub xeev qhuav zoo ntawm cov qauv engineering.

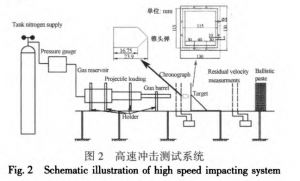

2. 3 Impact Experiments

Qhov kev sim siab ceev ntawm CFRP laminate tau ua rau ntawm lub tshuab cua kub ceev nrog txoj kab uas hla ntawm 15 hli. Cov cuab yeej ntsuas kev kub ceev (saib daim duab 2) suav nrog cov phom cua kub ceev, cov cuab yeej laser ceev ntsuas ua ntej thiab tom qab kev cuam tshuam, cov mos txwv lub cev, cov qauv kev teeb tsa (sab saum toj sab xis ntawm daim duab 2), thiab cov mos txwv lub cev kev nyab xeeb rov qab ntaus ntawv. Cov mos txwv lub cev yog lub taub hau lub taub hau cylindrical mos txwv (Daim duab 2), thiab qhov ntim ntawm cov mos txwv yog 24. 32 g nrog txoj kab uas hla ntawm 14. 32 hli; Kev cuam tshuam ceev yog 45 m / s (tshwj xeeb lub zog 46 J), 68 m / s (kev cuam tshuam lub zog 70 J), 86 m / s (kev cuam tshuam lub zog 90 J) cuam tshuam.

2. 4 Kev puas tsuaj ntawm cov qauv

Tom qab raug cuam tshuam los ntawm kev cuam tshuam, cov xim carbon fiber ntau epoxy composite laminate txheej txheej edgout phaj yog siv los kuaj xyuas qhov cuam tshuam sab hauv ntawm CFRP laminate phaj, thiab qhov projection cheeb tsam ntawm qhov cuam tshuam kev puas tsuaj yog ntsuas los ntawm cov duab tsom xam software UTwim, thiab cov ncauj lus kom ntxaws nta ntawm kev puas tsuaj cross-sectional yog soj ntsuam los ntawm scanning electron microscope thiab ultra-dep system.

3 Cov txiaj ntsig thiab kev sib tham

3. 1 Cov yam ntxwv ntawm kev nqus dej noo

Ib tug tag nrho ntawm 37. 7 d, qhov nruab nrab ntawm saturated noo noo nqus yog 1. 780%, nrog ib tug diffusion tus nqi ntawm 6. 183x10. 7 l2/s. Kev nqus dej noo ntawm CFRP laminate specimen yog pom nyob rau hauv daim duab 3. Raws li pom tau los ntawm daim duab 3, qhov pib loj hlob ntawm qhov nqus nqus dej ntawm cov qauv yog linear, tom qab theem linear, qhov kev loj hlob ntawm cov dej nqus dej pib poob, nce mus txog qib tsis tu ncua tom qab txog 23 d d. Yog li ntawd, kev nqus dej noo ntawm cov qauv ua raws li ob theem ntawm kev nqus dej noo: thawj theem ntawm kev nqus dej noo yog vim qhov sib koom ua haujlwm ntawm qhov kub thiab txias, noo noo los ntawm cov khoom nws tus kheej muaj qhov pores, qhov, tawg thiab lwm yam tsis xws luag kis mus rau sab hauv ntawm cov khoom; Cov dej diffusion qeeb thiab maj mam ncav cuag saturation nyob rau theem no.

3. Cov yam ntxwv kev puas tsuaj ntawm 2-txheej laminate board

Kev cuam tshuam ceev ntawm 86 m / s thaum cov qauv pem hauv ntej, sab nraub qaum ntawm daim ntawv qhia pom kev puas tsuaj, los ntawm cov qauv hauv chav sov qhuav, ntub dej kub saturation piv rau pem hauv ntej kev puas tsuaj zoo li, ob qho piv txwv ntawm qhov cuam tshuam, vim yog lub hauv paus tawg, nws kev puas tsuaj raws li thawj txheej ntawm fiber ntau muaj qee yam plam. Qhov no ua rau pem hauv ntej ua rau lub ntsej muag elliptical lossis duab plaub, thiab ntxiv rau qhov tuaj yeem pom qhov tawg hauv substrate, cov fibers tuaj yeem pom tawg. Los ntawm cov qauv hauv chav qhuav qhuav, ntub dej kub saturation qauv nyob rau sab nraum qab ntawm qhov kev puas tsuaj ntawm cov duab tuaj yeem pom tau tias sab nraub qaum ntawm qhov cuam tshuam kev taw qhia muaj qee qhov bulge, thiab nthuav tawm cov kab nrib pleb. Nws yog qhov pom tseeb tias qhov tawg ntawm fiber ntau, lub hauv paus tawg thiab qhov tawg ntawm interlayer (txheej txheem) peb hom kev puas tsuaj, qhov kawg ntawm cov fiber ntau yog lifted tab sis tsis tawg, tsuas yog txheej thiab fiber ntau / puag tawg. Cov pob txha fiber ntau kuj txawv, raws li tuaj yeem pom los ntawm kev sib piv ntawm kev puas tsuaj rau pem hauv ntej thiab nraub qaum. Lub hauv ntej ua rau tawg ntawm fiber ntau thiab substrate vim compression thiab shear. Lub nraub qaum yog vim ncab ua rau cov fiber ntau tawg thiab txheej txheej substrate. Daim duab 4 yog kev poob siab ceev ntawm 45 m / s, 68 m / s, 86 m / s thaum cov qauv hauv kev puas tsuaj C scan. Qhov chaw qhia los ntawm kwv yees li puag ncig l grey kab ntawm qhov nruab nrab ntawm daim duab yog thaj tsam ntawm qhov kev puas tsuaj. Cov kab dub saum toj no thiab hauv qab txhua daim ntawv me me qhia txog thaj chaw rau sab nraub qaum ntawm cov qauv. Qhov chaw cim nyob rau hauv kab dawb hauv daim duab (b) (d) (f) yog qhov kev puas tsuaj sab hauv rau cov qauv raws tus ciam teb. Daim duab qhia tau hais tias qhov cuam tshuam lub zog nce raws li qhov nrawm ntawm qhov cuam tshuam nce. Cov phaj laminated tuaj yeem nqus tau ntau lub zog thaum muaj kev cuam tshuam (saib daim duab 6 rau qhov tshwj xeeb), ua rau thaj tsam ntawm kev puas tsuaj ntawm laminate: los ntawm kev sib piv cov qauv ntawm chav sov qhuav nrog cov duab ntawm cov ntaub ntub dej kub saturation, nws tuaj yeem pom tau tias muaj kev puas tsuaj sab hauv (kab dawb) ntawm cov qauv tsim raws li tus ciam teb ntawm cov txheej txheem ntub dej ntawm cov txheej txheem tseem ceeb. Lub plasticization ntawm lub substrate nyob rau hauv lub laminate phaj thiab qhov tsis muaj zog ntawm fiber-puag interface ua rau ciam teb muaj qee yam cuam tshuam rau lub phaj laminate thaum lub sij hawm cuam tshuam. Raws li daim duab, qhov chaw rov qab tev tawm (kab dub) ntawm cov qauv hauv lub xeev qhuav tsis txawv ntau ntawm lub xeev ntub dej kub saturation.

3. Cov ncauj lus kom ntxaws txog kev puas tsuaj ntawm 3-txheej vaj huam sib luag

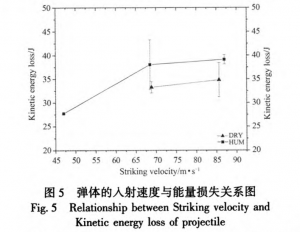

Daim ntawv qhia txog kev puas tsuaj ntawm CFRP txheej sib koom ua ke, coj los ntawm ultra-depth 3D microsystem thiab daim iav electron scanning, nrog rau kev cuam tshuam ceev ntawm 45 m / s, qhuav thiab ntub thiab kub, qhia tau hais tias kev puas tsuaj ntawm cov qauv hauv ob lub xeev suav nrog peb hom kev puas tsuaj: fiber ntau tawg, pob tawg thiab interlayer tawg. Tab sis lub hauv paus ntawm ob qhov qauv yog tawg txawv. Kev tawg ntawm lub substrate nyob rau hauv qhuav lub xeev yog tawg ntawm kev sib txuas ntawm fiber thiab substrate. Txawm li cas los xij, qhov tawg ntawm lub substrate tom qab ntub kev kho cua sov yog nrog los ntawm cov fragments ntawm substrate ntog tawm. Wold-esenbet thiab lwm yam ntaub ntawv nyob rau hauv ntub thiab kub ib puag ncig ntawm qhov cuam tshuam kev ua tau zoo ntawm cov qauv ntawm cov qauv thiab fiber ntau substrate interface degradation ua ke txiav txim siab, nyob rau hauv lub ntub kub ib puag ncig, CFRP txheej phaj nyob rau hauv lub resin puag kev nqus ntawm ib tug npaum li cas ntawm cov dej, seeping dej yuav ua rau cov resin substrate yaj. Cov pa roj carbon fiber ntau tsis nqus, tom qab ntawd yuav tsum muaj kev nthuav dav ntub dej ntawm ob qho tib si, qhov sib txawv no ua rau qhov sib cuam tshuam ntawm substrate thiab fiber ntau, txo lub zog ntawm substrate. Thaum raug cuam tshuam rau kev thauj khoom, cov substrate fragments tau yooj yim tso tawm, ua rau muaj qhov sib txawv ntawm qhov kub ntawm chav tsev kub qauv kev puas tsuaj cuam tshuam. Los ntawm cov txheej txheem ntxaws ntawm daim iav hluav taws xob scanned, nws tuaj yeem pom tias qhov tawg ntawm cov ntub dej thiab kub tom qab lub cev yog feem ntau yog qhov tawg ntawm cov xovxwm so, thaum lub cracking ua ntej ntub cua sov yog nkig, thiab kab rov tav shear tawg ntawm cov khaubncaws sab nraud povtseg yog pom tseeb dua. Los ntawm optical microscope hauv daim duab, nws tuaj yeem pom tias cov ntaub ntawv kev puas tsuaj sib txawv hauv ob qhov xwm txheej, thiab lub xeev qhuav yog ib qho kev puas tsuaj ntawm ib qho kev sib tshuam. Txhawm rau txiav qhov kev puas tsuaj feem ntau, tom qab ntub cov cua sov rau daim ntawv ntawm kev puas tsuaj nrog rau cov txheej txheem kev puas tsuaj tseem ceeb, qhov kev faib ua feem ntawm cov txheej txheem kev puas tsuaj nthuav dav. Nws tuaj yeem pom los ntawm lub kaum sab xis ntawm kev puas tsuaj mechanism thiab lub zog nqus cov yam ntxwv. Mei Zhiyuan muab tso rau pem hauv ntej ob theem ntawm kev ntxeem tau qhov projectile: txiav theem thiab ntu ntu ntu ntu. Lub cheeb tsam A nyob rau hauv cov qauv ntub dej yog qhov shear intrusion theem kev puas tsuaj, feem ntau vim hais tias nyob rau hauv cov txheej txheem cuam tshuam, txheej txheej phaj yog compressed thiab sheared tsim ntawm kev puas tsuaj deformation, b cheeb tsam yog qhov nruam invasion theem kev puas tsuaj. Cov theem no feem ntau yog los ntawm kev txo qis ntawm cov mos txwv lub cev nkag mus rau hauv qhov kev txiav txim ntawm qhov kev ntxhov siab ntawm cov txheej txheem fiber ntau, thiab lub zog tsuas yog hloov mus rau hauv fiber ntau stretch strain zog thiab lub zog interlayer tawg (l 51), kom cov fiber ntau tawg el thiab yav dhau los fiber ntau so tsis nyob rau hauv ib txoj kab ncaj nraim. Hauv cov qauv qhuav, qhov tshwm sim no tsis pom tseeb, thiab kev puas tsuaj ntawm cov phaj yog qhov hnyav dua, cov phaj txheej muaj lub xeev tawg. 3. 4 Absorption zog thiab damagehole projection cheeb tsam tsom xam daim duab 5 qhia txog kev sib raug zoo ntawm qhuav chav tsev kub thiab ntub dej kub saturation ntawm lub launch ceev thiab lub zog poob ntawm lub cev, ntawm qhov teeb meem ceev ntawm txog 45 m / s, lub qhuav chav tsev kub ntawm cov mos txwv tag nrho rebound, yog li tsis pom nyob rau hauv daim duab. Raws li tuaj yeem pom los ntawm daim duab 7, thaum qhov kev ntsuam xyuas tau kuaj nyob rau hauv ntub dej thermal saturation, cov mos txwv lub zog poob yog qhov hnyav, thiab lub peev xwm nqus ntawm cov qauv tom qab ntub dej kho cua sov nce.

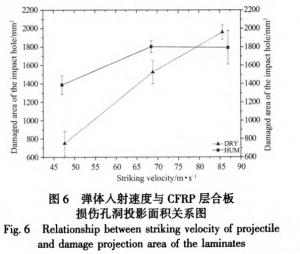

Daim duab 6 yog daim duab kos duab ntawm qhov projection cheeb tsam ntawm cov mos txwv lub cev qhov xwm txheej ceev thiab CFRP txheej puas lub qhov (cov kab grey cim ib feem ntawm daim duab 4), daim duab qhia (4), (5), (6) tuaj yeem pom: (1) nrog kev nce ntawm qhov cuam tshuam ceev, CFRP txheej txheej puas lub qhov projection cheeb tsam nce ; (2) Qhov loj dua qhov kev puas tsuaj ntawm chav tsev. ntawm ntub dej saturation; (3) Thaum qhov cuam tshuam ceev yog li 45 m / s, qhov projection cheeb tsam ntawm qhov puas ntawm lub phaj laminated tom qab ntub dej kub kho yog ntau dua qhov projection cheeb tsam ntawm lub laminated phaj puas lub qhov nyob rau hauv lub qhuav chav tsev kub xeev. ntub thermal saturation qauv kev puas tsuaj l-qhov projection cheeb tsam tau nce los ntawm 85. 1% thiab nyob rau ntawm ib tug poob siab ceev ntawm txog 68 m / s, lub laminated phaj nyob rau hauv ib tug ntub thiab thermal saturation xeev nce los ntawm 18. 10%, tus nqi nqus (Daim duab 5) nce 15. 65%; Ntawm qhov cuam tshuam ceev ntawm li 88 m / s, lub laminated phaj nyob rau hauv ntub thiab thermal saturation xeev tau txo los ntawm 9. 25%, tus nqi nqus tseem nce los ntawm 12. 45%.

Raws li kev tshawb fawb tau los ntawm Yucheng Zhong thiab lwm yam khoom, cov dej noo nqus ntawm carbon fiber-reinforced composite cov ntaub ntawv txhim kho cov elastic txwv thiab cuam tshuam tsis kam ntawm lub laminate phaj, thiab sib txuas qhov projected cheeb tsam ntawm lub puas qhov ntawm lub qhuav chav tsev kub specimen thiab cov ntub dej kub saturation specimen nyob rau hauv daim ntawv no (Daim duab 4 nyob rau hauv lub grey bullet projection thiab qhov kev sib raug zoo ntawm txoj kab nruab nrab) CFRP txheej kev puas tsuaj lub qhov, thiab cov txheej txheej puas ntawm CFRP txheej koom ua ke tuaj yeem sib piv thaum qhov cuam tshuam ceev yog tib yam thiab qis. Qhov chaw puas ntawm qhov ntub dej kub saturation specimen kuj loj. Qhov no yog vim kev kho cua sov ntub ua rau CFRP txheej substrate plasticization, tsis muaj zog fiber ntau thiab substrate interface thiab interlayer kev ua tau zoo, nyob rau hauv qhov cuam tshuam, ntub dej kub saturation xeev ntawm cov qauv txheej txheej kev puas tsuaj nthuav dav, feem ntawm kev puas tsuaj nce. Raws li Wu Yixuan thiab lwm yam kev sim paub tias qhov cuam tshuam lub zog nyob rau hauv txoj kab ntsug paving yog tsuas yog absorbed los ntawm resin substrate, ces cov plasticization ntawm lub substrate ua rau cov ntub thiab kub saturation specimen nqus ntau zog thaum lub sij hawm cuam tshuam cov txheej txheem, txhim kho qhov cuam tshuam tsis kam, thiab nce qhov projection ntawm qhov puas tsuaj; CFRP laminate kev puas tsuaj tsis tau txuas ntxiv, qhov cuam tshuam tau xaus, yog li thaum qhov cuam tshuam nrawm dua, kev kho cua sov ntub ntawm CFRP laminate qhov kev puas tsuaj qhov projection tsis loj, tab sis vim yog plasticization ntawm substrate resin, lub peev xwm nqus tau tseem nce ntxiv.

4 Cov lus xaus

(1) Nrog rau qhov nce ntawm qhov cuam tshuam, qhov projected thaj tsam ntawm qhov kev puas tsuaj ntawm carbon fiber reinforced epoxy resin composite (CFRP) laminate nce, thiab kev loj hlob ntawm qhov kev puas tsuaj 孑L qhov nyob rau hauv cov qauv ntawm chav tsev qhuav kub yog siab dua li nyob rau hauv ntub tshav kub saturation. Loj: (2) Thaum qhov cuam tshuam tshaj tawm yog 45 m / s, qhov kev puas tsuaj qhov projection ntawm CFRP laminate nyob rau hauv ntub tshav kub saturation xeev yog nce los ntawm 85. 11%, thaum qhov cuam tshuam tshaj tawm yog 68 m / s, qhov kev puas tsuaj projection cheeb tsam ntawm CFRP laminate nyob rau hauv ntub tshav kub saturation xeev yog nce los ntawm 18% CFRP lub xeev. 10%, qhov cuam tshuam ceev yog 86m / s. Lub wetted-saturated cFRP laminate qhov kev puas tsuaj qhov projection yog txo los ntawm 9.9% piv nrog rau chav qhuav kub cFRP laminate. 25% yog '; (3) Tom qab cFRP laminate raug cuam tshuam los ntawm qhov kub thiab av noo ib puag ncig, qhov kev ua tau zoo ntawm interlayer ntawm laminate yog txo, uas ua rau nthuav dav ntawm thaj chaw delamination.

Post lub sij hawm: Jun-24-2019