1. Intshayelelo

Ikhabhoni ifayibha eyomelezwe epoxy composite (CFRP) ineengenelo ezininzi ezinje ngoxinaniso oluphantsi, amandla athile aphezulu, ukuqina okuthe ngqo okuphezulu, ukumelana nokudinwa, ukuxhathisa umhlwa kunye neempawu ezilungileyo zoomatshini. Isetyenziswa ngokubanzi kwi-aerospace kunye nezinye izakhiwo ezinobungozi bokusingqongileyo, ubushushu obumanzi kunye nefuthe. Impembelelo yezinto ezisingqongileyo kwizinto eziphathekayo iya icaca ngakumbi. Kwiminyaka yakutshanje, abaphengululi basekhaya nabangaphandle baye benza inani elikhulu lophononongo kwiziphumo zokusingqongileyo ezishushu nezifumileyo kwiicomposites zeCFRP [1] kunye nefuthe lempembelelo kwiicomposites zeCFRP. Uphononongo lufumene ukuba impembelelo yendawo eshushu nefumileyo kwimixube yeCFRP ibandakanya ukwenziwa kweplastiki ye-matrix [2, ukuqhekeka [31 kunye neempawu zojongano olubuthathaka lwefayibha-matrix [2'3'5], ukugoba okuhlanganisiweyo kweCFRP kunye nokunyuka kwexesha lonyango lobushushu obumanzi) Iipropati zomatshini wokwenziwa komsebenzi [2, ukhokelo kunye neempawu zokucheba ze-interlaminar zibonise iimpawu zokucheba [2, 13 kunye ne-6 '6'. Woldesenbet et al. [I-8,9] ifunde iimpembelelo zemishini yeengqungquthela kumazinga aphezulu oxinzelelo emva kokunyanga kobushushu obumanzi, kwaye ifumene ukuba indawo eshushu kunye neyomanzi iphucule amandla eempembelelo ze-composites. Kutyhilwa ukuba ukufunxwa kokufuma kwezinto ezidibeneyo kunokuphucula impembelelo yeempawu zoomatshini bezinto eziphantsi kweemeko ezithile, ezihluke kakhulu kwiziphumo zovavanyo phantsi kweemeko ze-quasi-static. Umsebenzi wangoku omkhulu wophando sisiphumo sobushushu obufumileyo (kuquka ukuntywiliselwa kwamanzi) kwiipropati zempembelelo yesantya esisezantsi sefayibha eyomeleziweyo yentlaka yentlaka edityanisiweyo. U-Pan Wenge et al [10] bafunde iipropathi zokucinezela ze-fiberglass ephindwe kabini ephothiweyo / i-epoxy composite laminates emva kwempembelelo yesantya esisezantsi kwiqondo lobushushu begumbi naphantsi kweemeko ezishushu nezifumileyo (65 °C ukuntywiliselwa emanzini). 4. I-laminate phantsi kwendawo eshushu kunye neyomanzi ifunyenwe emva kokutshatyalaliswa kwesantya esiphantsi. Ukusebenza koxinzelelo kuncitshiswe kakhulu. Karasek et al. [1] ufunde imiphumo yomswakama kunye nobushushu kwimpembelelo ye-graphite / epoxy composite, kwaye wayifumana kwiqondo lokushisa eliphantsi kunye neendawo zokushisa zegumbi. Ukufuma kunempembelelo encinci kumandla okuqala kunye nokufunxa amandla komonakalo. U-Yucheng zhong et al [12,13] wenze uvavanyo lwempembelelo yesantya esisezantsi kwiilaminates ezihlanganisiweyo emva kokunyanga ubushushu obumanzi. Kugqitywa ukuba indawo eshushu kunye neyomileyo inciphisa kakhulu umonakalo wempembelelo ye-laminate. Ukuphucula ukuxhathisa impembelelo ye-laminates. UKrystyna et al. [14] ifunde impembelelo yesantya esisezantsi se-aramid-glass fiber / epoxy composite emva konyango lobushushu obumanzi (70 °C ukuntywiliselwa kwamanzi), kwaye yafumana indawo encinci yomonakalo emva konyango lobushushu obumanzi. Oku kubangela umonakalo we-delamination ngaphakathi kwesampulu, ethatha amandla amaninzi ngexesha leempembelelo kwaye inqanda ukubunjwa kwe-delamination. Inokubonwa apha ngasentla ukuba impembelelo yendawo yobushushu obumanzi kumonakalo wempembelelo yezinto ezidibeneyo zinempembelelo yokukhuthaza kunye nefuthe elibuthathaka. Ngoko ke, uphando olongezelelweyo kunye nokuqinisekiswa kuyafuneka. Ngokwempembelelo, u-Mei Zhiyuan et al [15] ucebise kwaye waseka inqanaba elimibini (ukungena kwe-shear kunye nokungena okuqhubekayo) imodeli yohlalutyo lwe-dynamics ye-fiber-reinforced composite laminates phantsi kwempembelelo yesantya esiphezulu. Guiping Zhao et al. [16] iqhube iintlobo ezintathu zezantya ezahlukeneyo (ngaphantsi kwe, zilingana kwaye zinkulu kunesantya somda we-ballistic) ekusebenzeni kwempembelelo kunye nomonakalo wesampuli emva kweentlobo ezintathu ze-laminates, kodwa ayizange ibandakanye impembelelo yendawo yokushisa emanzi kumonakalo wempembelelo. . Ngokusekwe kolu ncwadi lungasentla, uphando olunxulumeneyo malunga nempembelelo yendawo emanzi kunye neshushu kwifiber eqinisiweyo ye-composite laminates kusafuneka iphononongwe ngakumbi. Kweli phepha, iimpawu zomonakalo wempembelelo yobushushu obumanzi obugcwele i-carbon fiber / i-epoxy composite laminates phantsi kwe-70 °C yeemeko zokuhlambela kwamanzi zafundwa. Iimpembelelo zokusingqongileyo ezishushu kunye nezifumileyo kwiimpawu zokungaphumeleli kweempembelelo ze-composites zahlalutywa ngokuthelekisa kunye neesampuli zokushisa kwegumbi elomileyo. Kuvavanyo, i-CFRP laminates yachaphazeleka kwi-CFRP laminates kwi-45 m / s, 68 m / s kunye ne-86 m / s. Isantya ngaphambi nasemva kwempembelelo iye yalinganiswa. Impembelelo yendawo eshushu kunye nefumileyo ekusebenzeni kwamandla okufunxa kwe-laminates yahlalutywa. I-Ultrasonic c-scan yayisetyenziselwa ukufumanisa umonakalo wangaphakathi we-laminate, kwaye impembelelo yesantya sempembelelo kwindawo eqhekekileyo yahlaziywa. I-electron yokuskena i-microscope kunye ne-ultra-depth-depth-depth-depth-depth-depth-depensional microscopic system yasetyenziselwa ukujonga iimpawu ze-mesoscopic zomonakalo wesampulu, kwaye umonakalo wesampulu uhlalutyelwe bubushushu obumanzi. Impembelelo yeempawu.

2 Imathiriyeli yovavanyo kunye neendlela

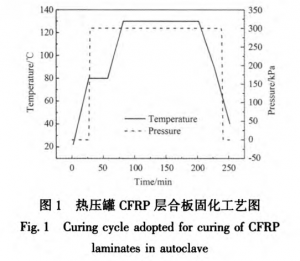

2. Izinto ezi-1 kunye nokulungiselela

I-Carbon fiber epoxy resin (T300 / EMl 12) i-composite material, ukucwiliswa kwangaphambili okunikezelwe nguJiangsu Hengshen Co., Ltd., i-single-layer pre-immersion thickness of 0. 137 mm kunye ne-fiber volume fraction ye-66%. Iphaneli ye-laminate ibekwe kumgangatho woluhlu. , ubukhulu 115mm x 115mln. Inkqubo yokwenziwa kwetanki yokucofa okushushu iyasetyenziswa. Umzobo wenkqubo yokunyanga olungiselelwe yinkqubo uboniswe kuMzobo 1. Okokuqala phakamisa indawo yokuhlala ukusuka kwiqondo lokushisa ukuya kwi-80 oC kwinqanaba lokufudumala kwe-1 ukuya kwi-3 oC / min, uze ufudumale kwi-30 min, ukushisa ukuya kwi-130 oC kwizinga lokufudumala kwe-l13 oC / min, gcina ukufudumala kwi-120 min, ukunciphisa ukuya kwi-60.0C ngesantya sokupholisa rhoqo, kwaye emva koko ususe uxinzelelo kunye nokukhululwa, kwaye ukhulule.

2. 2 Unyango lobushushu obumanzi

Emva kokulungiswa komzekelo, isampulu yaphathwa ngobushushu obumanzi ngokuhambelana nenkcazo ye-HB 7401-96.171 "I-resin-based composite composite layer emanzi eshushu bume indlela yokufunxa ukufuma". Okokuqala, i-specimen ifakwe kwigumbi lokumisa le-thermostatic kwi-70 degrees C ukuze yome. Ukulinganisa rhoqo usebenzisa i-balances de ukulahlekelwa kwekhwalithi ye-specimen kuzinzile kungabi ngaphezu kwe-0. 02%, ixabiso elirekhodiweyo ngeli xesha liyi-Engineering Dry Mass G. Emva kokumisa, i-specimen ifakwe kwi-70 degrees C yamanzi kunyango lobushushu obumanzi. Ngokwenkcazo ye-HB 7401. Indlela echazwe kwi-96 "ilinganisa umgangatho wesampuli yonke imihla, ebhalwe njenge-Gi, kwaye irekhoda utshintsho lokufunxa ukufuma Mi. Inkcazo yokufunxa ukufuma kwe-CFRP isampuli ye-laminate yile:

Ifomula icacisiwe: Mi kukufunxa ukufuma kwesampulu, i-Gi ngumgangatho emva kokuba isampulu ifunxa ukufuma, g, hamba ngumgangatho owomileyo wobunjineli bomzekelo.

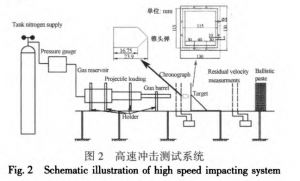

2. 3 IiMvavanyo zeMpembelelo

Uvavanyo lwempembelelo yesantya esiphezulu kwi-CFRP laminate lwenziwa kwi-cannon yomoya enesantya esiphezulu kunye nobubanzi be-15 mm. Isixhobo sovavanyo lwempembelelo yesantya esiphezulu (jonga uMzobo 2) ubandakanya umpu womoya onesantya esiphezulu, isixhobo sokulinganisa isantya selaser ngaphambi nasemva kwempembelelo, umzimba wembumbulu, umzobo wofakelo lomfanekiso (kwikona ephezulu ngasekunene kuMzobo 2), kunye nesixhobo sokubuyisa ukhuseleko lomzimba. Umzimba wembumbulu yi-cone-headed bullet cylindrical (Umfanekiso 2), kunye nomthamo we-bullet ngu-24. 32 g kunye nobubanzi be-14. 32 mm; isantya sempembelelo yi-45 m / s (amandla empembelelo 46 J), 68 m / s (amandla empembelelo 70 J), 86 m / s (impembelelo yamandla 90 J) impembelelo.

2. 4 Ukufunyanwa komonakalo wemizekelo

Emva kokuchatshazelwa yimpembelelo, i-carbon fiber color epoxy composite composite laminate layer edgout plate isetyenziselwa ukufumanisa umonakalo wangaphakathi we-CFRP laminate plate, kunye nommandla woqikelelo lwendawo yomonakalo wempembelelo ilinganiswa ne-software yohlalutyo lomfanekiso we-UTwim, kunye neempawu ezicacileyo zokutshatyalaliswa kwe-cross-sectional zibonwa ngokuskena i-electron microscope kunye ne-ultra-deep field ultra-de.

3 Iziphumo kunye neengxoxo

3. 1 Imizekelo yeempawu zokufunxa ukufuma

Iyonke i-37. 7 d, i-avareji yokufunxa ukufuma okugcweleyo yi-1. 780%, kunye nesantya sokusasazwa kwe-6. 183x10. 7llnl2/s. Ijika lokufunxa ukufuma kwesampulu yeCFRP laminate iboniswe kuMfanekiso 3. Njengoko kunokubonwa kuMzobo 3, izinga lokukhula lokuqala lokufunxa ukufuma kwesampulu linear, emva kwenqanaba lomgca, izinga lokukhula lokufunxa ukufuma liqala ukuhla, lifikelela kwinqanaba elizinzileyo emva kwexesha lokufuma emva kwe-23 yokufuma, kunye nokufikelela kwixesha lokufuma. Ngoko ke, ukunyuswa komswakama we-specimen kuhambelana nemo ye-absorption ye-absorption yemigangatho emibini: inqanaba lokuqala lokufunxa umswakama ngenxa yesenzo esidibeneyo sokushisa kunye nomswakama, umswakama ngokusebenzisa izinto ngokwazo ziqulethe ii-pores, imingxuma, iintanda kunye nezinye iziphene ezisasazeka ngaphakathi kwezinto; Ukusasazwa kwamanzi kuyacotha kwaye ngokuthe ngcembe kufikelela kwi-saturation kweli nqanaba.

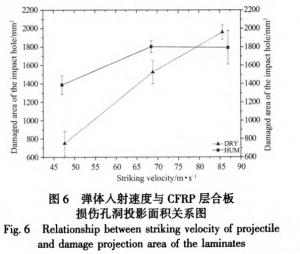

3. Iimpawu ezibonakalayo zokutshatyalaliswa kwebhodi ye-laminate ye-2-layer

Isantya sempembelelo ye-86 m / s xa umboniso wangaphambili, umva wemephu yeprofayile yokutshatyalaliswa ebonakalayo, ngesampulu yobushushu begumbi elomileyo, isampuli emanzi eshushu yokutshatyalaliswa kwangaphambili ifana, imizekelo emibini kwimpembelelo, ngenxa yokuqhekeka kwesiseko, ukutshatyalaliswa kwayo kunye nomgca wokuqala wefayibha ine-slip ethile. Oku kubangela ukuba umphambili unike i-elliptical okanye i-rectangular shape, kwaye ngaphezu kokukwazi ukubona ukuqhekeka kwi-substrate, iifayili zingabonwa ukuba ziphule. Ngesampulu yobushushu begumbi elomileyo, isampulu emanzi yokugcwala eshushu ngasemva kokutshatyalaliswa kwemilo inokubonwa ukuba umva ecaleni kwendlela yempembelelo ineqhuma elithile, kwaye inikezela ngokuqhekeka okumise okunqamlezileyo. Kucacile ukuba i-fiber fracture, isiseko sokuqhekeka kunye ne-interlayer fracture (i-layering) iindlela ezintathu zokutshabalalisa, inxalenye yokugqibela yefiber iphakanyisiwe kodwa ayiphulwanga, i-layer kuphela kunye ne-fiber / isiseko sokuqhekeka. Ukuqhekeka kwefayibha kwahlukile, njengoko kunokubonwa ngokuthelekisa umonakalo wangaphambili nasemva. Umphambili ubangela ukuphuka kwefiber kunye ne-substrate ngenxa yoxinzelelo kunye nokucheba. Umva ngenxa yokwelula kubangele ukuba i-fiber iphuke kwaye ilale i-substrate. Umzobo we-4 ukukhawuleza kwesantya se-45 m / s, i-68 m / s, i-86 m / s xa i-specimen yomonakalo wangaphakathi we-C scan. Indawo eboniswe ngumgca ojikelezayo we-l grey kumbindi womzobo yindawo eqikelelweyo yomonakalo. Umgca omnyama ngasentla nangaphantsi kwetshathi encinci nganye ibonisa indawo yendawo yokukrazula ngasemva yomzekelo. Indawo ephawulwe kumgca omhlophe kumfanekiso (b) (d) (f) ngumonakalo wangaphakathi kumzekelo ecaleni komda. Igrafu ibonisa ukuba amandla empembelelo ayanda njengoko isantya sempembelelo sinyuka. Ipleyiti elaminethiweyo iyakwazi ukufunxa amandla amaninzi ngexesha leempembelelo (jonga umfanekiso wesi-6 ngexabiso elithile), okukhokelela kwindawo eyandayo yengqikelelo yomonakalo welaminate: ngokuthelekisa isampuli yobushushu begumbi elomileyo kunye nomfanekiso wesampulu emanzi yokugcwala okushushu, kunokubonwa ukuba kukho umonakalo wangaphakathi (umgca omhlophe) wesampulu eveliswe ecaleni komda kwingqikelelo emanzi-eshushu ngenxa yenkqubo yokuhluza okumanzi ngenxa yenkqubo yokuhluza. Iplastiki ye-substrate kwi-plate ye-laminate kunye nokunciphisa i-fiber-base interface kubangela ukuba umda ube nefuthe elithile kwi-plate ye-laminate ngexesha lenkqubo yempembelelo. Ngokomzobo, indawo yokuhluma ngasemva (umgca omnyama) we-specimen kwindawo eyomileyo ayifani kakhulu nemeko yokufudumala okumanzi.

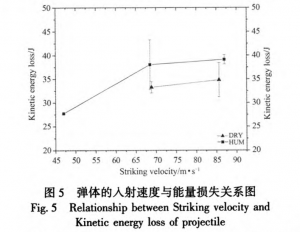

3. Iimpawu ezicacileyo ezitshabalalisayo zepaneli ye-3-layer

Imephu ye-Cross-Sectional umonakalo imbonakalo yepleyiti edibeneyo ye-CFRP, ethathwe yi-ultra-depth-depth 3D microsystem kunye nesibuko se-electron yokuskena, kunye nesantya sempembelelo ye-45 m / s, eyomileyo kwaye emanzi kwaye eshushu, ibonisa ukuba umonakalo we-specimen kuwo omabini la mazwe ubandakanya iindlela ezintathu zokutshatyalaliswa: ukuphuka kwefayibha, ukuqhekeka kwesiseko kunye nokuqhekeka kwe-interlayer. Kodwa isiseko semizekelo emibini siqhekezwe ngokwahlukileyo. Ukuqhekeka kwe-substrate kwimeko eyomileyo kuqhekezwe ekudibaneni phakathi kwefiber kunye ne-substrate. Nangona kunjalo, ukuchithwa kwe-substrate emva kokunyanga kokushisa okumanzi kuhamba kunye neziqhekeza ze-substrate eziwayo. Wold-esenbet kunye nezinye izinto kwindawo emanzi neshushu yokusebenza kwempembelelo yesakhiwo sesakhiwo kunye nefayibha substrate ujongano ukuwohloka ngokudibeneyo ezimisele ngokudibeneyo, kwindawo emanzi eshushu, ipleyiti yomaleko yeCFRP kwisiseko se-resin amava okufunxa isixa esithile samanzi, amanzi amdaka aya kubangela ukuba i-resin substrate inyibilike. I-carbon fiber ayifuni, ngoko kufuneka kubekho ukwanda okumanzi phakathi kwezi zibini, lo mahluko unciphisa ujongano phakathi kwe-substrate kunye nefiber, kunciphisa amandla e-substrate. Xa ziphantsi komthwalo wempembelelo, amaqhekeza e-substrate alahlwa ngokulula, okubangela ukubahluko kwi-interface yomonakalo wesampuli yegumbi elomileyo. Ukusuka kwisakhiwo esicacileyo sesibuko sombane esiskeniweyo, kunokubonwa ukuba ukuqhekeka kwesiseko somzimba omanzi kunye noshushu we-post-base ikakhulu kukuqhekeka okuxekethileyo kwekhefu lokushicilela, ngelixa ukuqhekeka phambi kobushushu obumanzi ubukhulu becala, kunye nokuqhekeka kwe-chear ethe tyaba phakathi kweengqimba kubonakala ngakumbi. Ukususela kwi-microscope ye-optical emfanekisweni, kunokubonwa ukuba iifom zokutshatyalaliswa zihluke kwiimeko ezimbini, kwaye imeko eyomileyo yi-per-inter-cut cut. Ukusika intshabalalo ubukhulu becala, emva kobushushu obumanzi bohlobo lwentshabalalo olukhatshwa yintshabalalo yomaleko obalulekileyo, umlinganiselo wentshabalalo eyandisiweyo yandiswa. Inokubonwa kwi-angle yendlela yokutshatyalaliswa kunye neempawu zokufunxa amandla. U-Mei Zhiyuan ubeke phambili izigaba ezibini ze-projectile invasion: inqanaba lokusika kunye nenqanaba lokuhlasela eliqhubekayo. Ummandla A kwisampulu emanzi eshushu yintshabalalo yenqanaba lokucheba, ikakhulu ngenxa yokuba kwinkqubo yempembelelo, ipleyiti yokubeka icinezelwe kwaye ichetywe ukubunjwa kokutshatyalaliswa kwentshabalalo, indawo b yintshabalalo yenqanaba eliqhubekayo lokuhlasela. Eli nqanaba libangelwa ikakhulu ngenxa yokunciphisa isantya sokungena komzimba wembumbulu phantsi kwesenzo secandelo loxinzelelo lwe-fibrous layer, kwaye amandla aguqulwa kakhulu abe yi-fiber stretch strain energy kunye ne-interlayer fracture energy (l 51), ukwenzela ukuba i-fiber break el kunye ne-fiber yangaphambili ikhefu ayikho kumgca othe tye. Kwisampulu esomileyo, le nto ayibonakali, kwaye umonakalo weplate unzima kakhulu, i-layer plate inesimo sokuqhekeka. 3. 4 Amandla okufunxa kunye nokuhlalutya kwendawo yeprojekthi yomonakalo Umzobo wesi-5 ubonisa ubudlelwane phakathi kobushushu begumbi elomileyo kunye nokugcwala okumanzi okushushu kwesantya sokuqalisa kunye nokulahleka kwamandla emzimbeni, kwisantya sesiganeko esimalunga ne-45 m / s, ubushushu begumbi elomileyo lembumbulu yonke iphinda ibuyele, ngoko ayiboniswanga kumfanekiso. Njengoko kunokubonwa kwi-Figure 7, xa uvavanyo luvavanywa phantsi kwe-thermal saturation emanzi, ilahleko yamandla embumbulu inzulu, kunye nomthamo wokufunxa wesampuli emva kokunyuka konyango lobushushu obumanzi.

Umzobo wesi-6 ngumzobo wegrafu yendawo yoqikelelo lwesantya somzimba wembumbulu kunye neCFRP umngxuma womonakalo umaleko (umgca ongwevu uphawula inxalenye yoMzobo 4), umzobo obanzi (4), (5), (6) unokubonwa: (1) kunye nokwanda kwesantya sempembelelo, umaleko weCFRP womonakalo womaleko womngxuma wonyuka kwindawo yokwanda; ukugcwala okushushu; (3) xa isantya sempembelelo simalunga nama-45 m/s, ummandla wentelekelelo womngxuma wepleyiti elaminethiweyo emva konyango lobushushu obumanzi mkhulu kakhulu kunommandla woqikelelo lomngxuma womonakalo wepleyiti elaminethiweyo kwindawo yobushushu begumbi elomileyo. Isampula yesampulu emanzi ye-thermal saturation umonakalo we-l-hole yengqikelelo inyuke ngama-85. 1% kunye nesantya somothuko malunga ne-68 m / s, ipleyiti edibeneyo kwindawo emanzi kunye ne-thermal saturation inyuke ngo-18. 10%, ixabiso lokufunxa (Umfanekiso 5) linyuke nge-15. 65%; Ngesantya sempembelelo esimalunga ne-88 m/s, ipleyiti elayitiweyo kwindawo emanzi kunye ne-thermal saturation yancitshiswa nge-9. 25%, ixabiso lokufunxa lisanyuka nge-12. 45%.

Ngokusekwe kwiziphumo zophando zeYucheng Zhong kunye nezinye iimveliso, ukufunxwa kokufuma kwezixhobo ezihlanganisiweyo zekhabhoni kuphucula umda we-elastic kunye nokumelana nempembelelo yepleyiti ye-laminate, kwaye idibanisa indawo eqikelelweyo yomngxuma womonakalo wesampulu yobushushu begumbi elomileyo kunye nomfanekiso wokugcwala okumanzi kweli phepha (Umfanekiso wesi-4 kumgca weprojekthi yobudlelwane kunye nesantya somzobo weprojekthi CFRP umaleko umonakalo umngxuma, kunye nomonakalo umaleko we CFRP umaleko ukujoyina ibhodi inokuthelekiswa xa isantya impembelelo iyafana kwaye iphantsi. Indawo yomonakalo wesaturation emanzi eshushu ininzi kakhulu. Oku kubangelwa unyango ubushushu emanzi yenza CFRP umaleko substrate plasticization, buthathaka ifayibha kunye substrate ujongano kunye nokusebenza interlayer, kwimpembelelo, imo yobushushu emanzi saturation yomzekelo ukwandiswa umaleko yomonakalo, umlinganiselo womonakalo unyukile. Ngokusekwe kwiWu Yixuan kunye nezinye iimvavanyo ziyazi ukuba amandla empembelelo kwindlela yokumisa ethe nkqo ifunxwa yi-resin substrate, emva koko i-plasticization ye-substrate yenza i-saturation emanzi kunye neshushu i-specimen ifunxe amandla amaninzi ngexesha lenkqubo yempembelelo, iphucula ukuxhathisa impembelelo, kwaye yandisa indawo yentelekelelo yomngxuma womonakalo; Umonakalo we-laminate CFRP awuzange unwenwe ngokupheleleyo, impembelelo iphelile, ngoko ke xa isantya sempembelelo siphezulu, unyango lobushushu obumanzi kwindawo yengqikelelo yomonakalo we-laminate CFRP ayisekho kakhulu, kodwa ngenxa yeplastiki ye-substrate resin, umthamo wokufunxa usakhula.

4 Izigqibo

(1) Ngokunyuka kwesantya sempembelelo, ummandla oqikelelweyo womngxuma womonakalo wekhabhoni ifayibha eyomeleziweyo epoxy resin composite (CFRP) i-laminate iyanda, kwaye izinga lokukhula lomonakalo 孑L umngxuma kwisampulu kwiqondo lobushushu legumbi elomileyo liphezulu kunolo liphantsi kobushushu bobushushu obumanzi. Enkulu: (2) Xa isantya impembelelo 45 m / s, ummandla ngqikelelo umonakalo CFRP laminate kwimo yobushushu emanzi saturation yonyuka ngo 85. 11%, xa isantya impembelelo yi 68 m / s, ummandla woqikelelo umonakalo CFRP laminate kwimo yobushushu ukuhluza ubushushu yande nge 18 % lobushushu igumbi xa kuthelekiswa ne-CFRP . I-10%, isantya sempembelelo yi-86m / s. Indawo yeprojekithi yomonakalo we-laminate yecFRP emanzi-saturated iyancipha nge-9.9% xa kuthelekiswa nobushushu begumbi elomileyo le-cFRP laminate. 25%; (3) Emva kokuba i-cFRP laminate ichaphazeleke kwindawo eshushu kunye neyomanzi, ukusebenza kwe-interlayer ye-laminate kuncitshisiwe, okubangelwa ukwandiswa kwendawo ye-delamination.

Ixesha lokuposa: Jun-24-2019