IZINKONZO NOBUNJINIRI - Ukubala Ngezinombolo kanye Nokuhlaziywa Kwedatha

I-Mechanics and Engineering — Izibalo Zezinombolo Nokuhlaziywa Kwedatha 2019 Academic Conference, Ephreli 19-21, 2019, Beijing

Ephreli 19-21, 2019, Beijing, China

Ukufunda Ngokuziphatha Okunwetshiwe Okunezingqimba Kweshidi Le-Laminates Ye-Carbon Fiber Ethuthukisiwe Eqinisiwe

Gong Yu1*, Wang Yana2, Peng Lei3, Zhao Libin4, Zhang Jianyu1

1Chongqing University, Chongqing, 400044, China

2I-China Aviation Research Institute Beijing Aeronautical Materials Research Institute, Beijing, 100095, China

3China Commercial Aircraft Beijing Civil Aircraft Technology Research Center, Beijing, 102211, China

4I-Beijing University of Aeronautics and Astronautics, Beijing, 100191, China

AbstractIsakhiwo se-laminate singenye yezindlela ezivame ukusetshenziswa kakhulu zokucushwa kwenhlanganisela yezinhlanganisela, kodwa i-delamination iba imodi yayo eyinhloko yokwehluleka ngenxa yezakhiwo ezibuthakathaka ze-interlaminar. Ucwaningo mayelana ne-multi-laminate stratification kanye nokuziphatha kokunwetshwa okuvame ukusetshenziswa emisebenzini yobunjiniyela bekulokhu kuyisihloko esishisayo ezifundweni. Kuleli phepha, imiphumela yocwaningo ye-carbon fiber reinforced composite delamination e-Chongqing University kanye nase-Beijing University of Aeronautics and Astronautics Fatigue Fracture Laboratory yethulwa kusukela ezicini ezimbili zocwaningo lokuhlola kanye nokulingiswa kwezinombolo. Ekugcineni, kulindelwe indlela yokuthuthukisa inkambu.

Amagama angukhiye:i-carbon fibre eyinhlanganisela eqinisiwe, i-laminate, i-delamination, i-stratification yokukhathala

isingeniso

Izinto ezihlanganisiwe zinezakhiwo ezinhle kakhulu njengamandla athile aphezulu kanye nokuqina okuqondile okuphezulu, futhi zisetshenziswe kabanzi ku-aerospace, ubuchwepheshe bamandla, kanye nezokuthutha zomphakathi kanye nokwakhiwa. Ngesikhathi sokucutshungulwa kanye nokusetshenziswa kwezinto ezihlanganisiwe, imicu kanye ne-matrix kuzobhekana namazinga ahlukene omonakalo ngaphansi komthwalo. Izindlela zokwehluleka ezivamile zama-laminates ayinhlanganisela zihlanganisa ukulimala kwe-interlayer nokulimala ngaphakathi kwezendlalelo. Ngenxa yokuntuleka kokuqiniswa ekuqondeni kokuqina, izici ze-lateral mechanical ze-laminate zimbi, futhi umonakalo we-delamination cishe ungenzeka ngaphansi kwemithwalo yangaphandle yomthelela. Ukwenzeka kanye nokwanda komonakalo we-stratified kuzoholela ekwehleni kokuqina kwesakhiwo namandla, futhi kubangele nezingozi eziyinhlekelele.[1-3]. Ngakho-ke, inkinga ye-delamination ikhathazeka kakhulu ngokuklanywa kwesakhiwo nokuhlaziywa kwamandla ezinto eziyinhlanganisela, futhi kuyadingeka ukutadisha ukuziphatha okunwetshiwe okuhlanganisiwe kwezinto eziyinhlanganisela.[4].

Ucwaningo mayelana nokuziphatha okunwetshiwe kwe-laminate

1. Ucwaningo lokuhlola

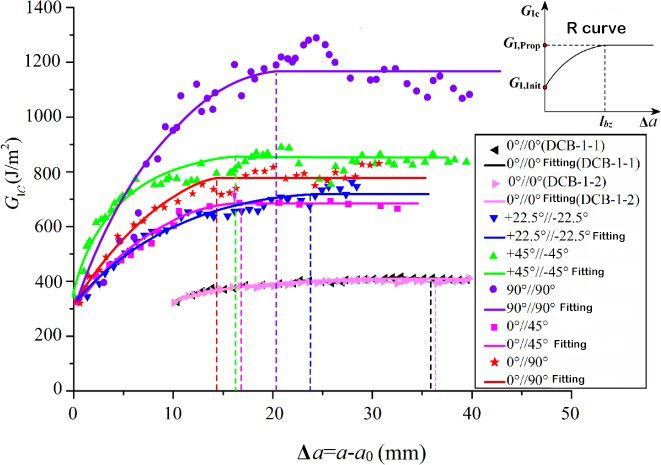

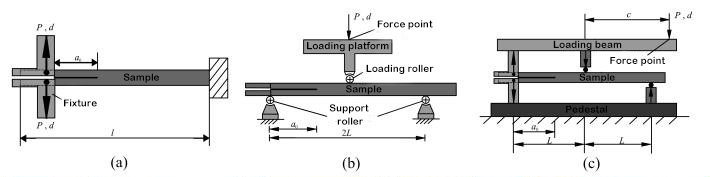

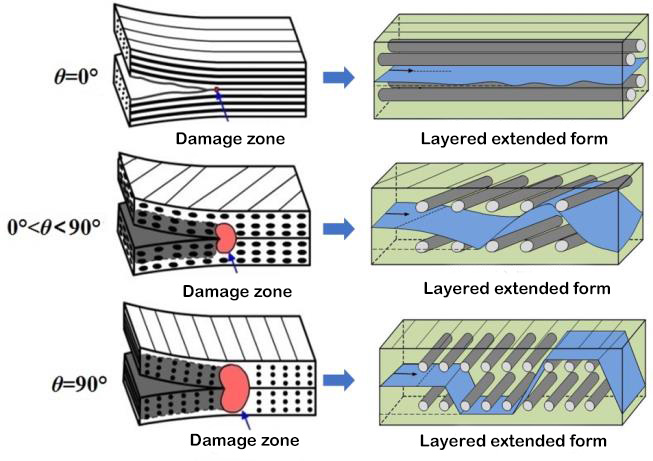

Ukuqina kokuphuka kwe-Interlaminar kuyipharamitha yesici sezakhiwo eziwumshini phakathi kwezingqimba eziyinhlanganisela. Kuye kwasungulwa amazinga okuhlola ahambisanayo ukuze kunqunywe ukuqina kokuphuka kwe-interlaminar kohlobo I, Uhlobo lwe-II kanye ne-I/II ye-hybrid unidirectional laminates. Imishini yokuhlola ehambisanayo iboniswa kuMfanekiso 1. Kodwa-ke, ama-laminates aneziqondiso eziningi zezinto ezihlanganisiwe avame ukusetshenziswa esakhiweni sangempela sobunjiniyela. Ngakho-ke, ucwaningo lokuhlola mayelana nokuziphatha kokuhlelwa nokunwetshwa kwama-laminates aneziqondiso eziningi kunokubaluleka okubaluleke kakhulu kwethiyori kanye nenani lobunjiniyela. Ukuqaliswa nokunwetshwa kwesendlalelo se-laminate enezingqimba eziningi kwenzeka phakathi kwezindawo zokusebenzelana ezinama-engeli ezendlalelo angavumelani, futhi ukuziphatha okunwetshiwe okunezingqimba kuhluke kakhulu kulokho kwama-laminates angaqondile, futhi indlela yokwandisa iyinkimbinkimbi kakhulu. Abacwaningi banezifundo zokuhlola ezimbalwa uma kuqhathaniswa nama-laminates anezikhombisi-ndlela eziningi, futhi ukunqunywa kokuqina kokuphuka kwe-interlaminar akukakasungulwa izinga lamazwe ngamazwe. Ithimba labacwaningi lasebenzisa i-T700 ne-T800 carbon fibre ukuze lidizayine izinhlobonhlobo zama-laminates ayinhlanganisela anama-engeli ahlukene wokuhlanganisa isixhumi esibonakalayo, futhi lahlola umthelela we-engeli yokubeka isixhumi esibonakalayo kanye nokuhlanganisa i-fiber ekuziphatheni okumile nokukhathala kwe-delamination. Kutholwe ukuthi i-fiber bridging eyenziwe unqenqema olulandelayo longqimba lunomthelela omkhulu ekuqineni kokuphuka kwe-interlaminar. Njengoba i-stratification ikhula, ukuqina kwe-interlaminar fracture kuzokhula kancane kancane kusuka kunani eliphansi lokuqala, futhi lapho i-stratification ifinyelela ubude obuthile, ifinyelela inani elizinzile, okungukuthi, i-R resistance curve phenomenon. Ukuqina kokuqala kokuphuka kwe-interlayer kucishe kulingane futhi kucishe kulingane nokuqina kokuphuka kwe-resin, okuncike ekuqineni kokuphuka kwe-matrix ngokwayo.[5, 6]. Kodwa-ke, amanani wesandiso sokuqina kokuqhekeka kwe-interlaminar wezindawo ezihlukene ahluka kakhulu. Kwethulwa ukuncika kwe-engeli yesendlalelo sesixhumi esibonakalayo. Ephendula lokhu kuncika, uZhao et al.[5]ngokusekelwe kumshini womzimba womthombo wokumelana ne-stratified, kubhekwa ukuthi inani lokuzinza kokuqina kokuphuka kwe-interlaminar liqukethe izingxenye ezimbili, ingxenye eyodwa ingumsebenzi wokuphuka kwesixhumi esibonakalayo sesendlalelo esingahlobene, kanti enye ingxenye ukulimala kwe-intralayer kanye ne-fiber. Umsebenzi wokuphuka okubangelwa ibhuloho. Ngokuhlaziywa kwesici esilinganiselwe senkambu yangaphambili yengcindezi yangaphambili enezingqimba, kutholakala ukuthi ingxenye yesibili yomsebenzi wokuphuka incike ekujuleni kwendawo yokulimala yangaphambili ye-delamination (njengoba kubonisiwe kuMfanekiso 3), futhi ukujula kwendawo yomonakalo ilingana ne-engeli yokubeka isixhumi esibonakalayo. Imodeli yetiyori yevelu yokuqina kohlobo lwe-I yokuqina evezwa umsebenzi we-sinusoidal we-engeli yesendlalelo esibonakalayo iyethulwa.

Gong et al.[7]yenze ukuhlolwa kwe-I/II hybrid stratification ngaphansi kwezilinganiso ezihlukene zokuhlanganisa, futhi yathola ukuthi i-I/II stratification ye-hybrid ku-laminate nayo inezici ezibalulekile zejika lika-R lokumelana. Ngokuhlaziywa kokuqina kwe-fracture phakathi kwezingcezu zokuhlola ezihlukene, kutholakala ukuthi inani lokuqala kanye nenani elizinzile lokuqina kwe-interlaminar fracture yesiqephu sokuhlola kukhula kakhulu ngokunyuka kwesilinganiso sokuxuba. Ukwengeza, ukuqina kokuqala nokuzinzile kokuphuka kwe-interlayer ngaphansi kwezilinganiso ezihlukene zokuxuba kungachazwa ngombandela we-BK.

Ngokuphathelene nokuhlukaniswa kokukhathala, i-fiber bridging ebalulekile nayo yabonwa ngesikhathi sokuhlolwa. Ngokuhlaziywa kwedatha yokuhlola, kutholakala ukuthi ukunwetshwa kokususwa kokukhathala kwento eyinhlanganisela kuthintwa “ijika lokumelana”, ukuze imodeli yezinga lokunwetshwa kokuhlelwa kokukhathala okungokwesiko kanye nenani lomkhawulo angasasebenzi. Ngokwesisekelo sokuhlaziywa kwethiyori, uZhang noPeng[4,8,9]yethule ukumelana nokunwetshwa kwe-delamination yokukhathala ukuze iveze amandla adingekayo ukuze kunwetshwe ukukhathala kwe-delamination yezinto eziyinhlanganisela, futhi yaphinde yahlongoza amandla obunzima obujwayelekile. Izinga lokukhishwa imodeli yezinga lokunweba elihlukaniswe ngokukhathala kanye nenani lomkhawulo lamapharamitha okulawula. Ukusebenza kwemodeli kanye nepharamitha ye-threshold evamile kuqinisekiswa ukuhlola. Ngaphezu kwalokho, uZhao et al.[3]icubungule ngokujulile imiphumela ye-fiber bridging, isilinganiso sokucindezeleka kanye nesilinganiso sokuxuba umthwalo ekuhlanganiseni kokukhathala nokuziphatha okunwetshiwe, futhi yasungula imodeli yesilinganiso sokunwebeka esilinganiselwe sokukhathala ngokucabangela umthelela wesilinganiso sokucindezeleka. Ukunemba kwemodeli kuye kwaqinisekiswa ukuhlolwa kokuhlelwa kokukhathala okunezilinganiso ezihlukene zokucindezeleka kanye nezilinganiso zokuxuba. Ngokwenani elingokomzimba lokukhathala okugxilile ukumelana nokunwetshwa kumodeli yesilinganiso sokunwebeka esijwayelekile sokukhathala, uGong et al.[1]nqoba ubuthakathaka bendlela yokubala engathola kuphela amaphuzu edatha ahlukene alinganiselwe ngokuhlolwa, futhi iqalise ukukhathala ngokombono wamandla. Imodeli yokuhlaziya yokubala ukumelana okunwetshiwe kwe-stratified. Imodeli ingakwazi ukubona ukunqunywa kobuningi bokuhlukaniswa kokukhathala nokumelana nokwanda, futhi inikeze ukusekelwa kwethiyori ekusetshenzisweni kwemodeli yesilinganiso sokunwebeka esilinganiselwe esijwayelekile sokukhathala.

Umdwebo 1 wedivayisi yokuhlola ene-stratified

Umdwebo 1 wedivayisi yokuhlola ene-stratified

Umfanekiso 2 Ukuqina kokuqhekeka kwe-Inter-layer R ijika lokumelana[5]

Umfanekiso 3 Indawo yokulimala yonqenqema enezendlalelo ehamba phambili kanye ne-stratified morphology enwetshiwe[5]

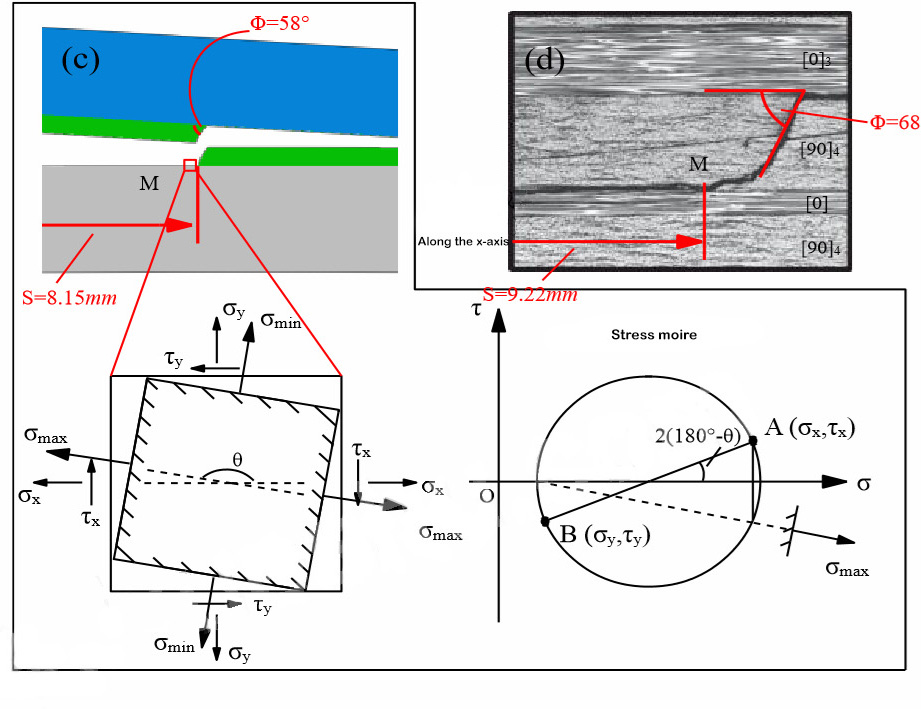

2. Ucwaningo lokulingisa izinombolo

Ukulingiswa kwezinombolo kokunwetshwa okunezingqimba kuwucwaningo lokuqukethwe olubalulekile emkhakheni wesakhiwo esiyinhlanganisela. Lapho ubikezela ukwehluleka kwe-delamination kwama-laminates ahlanganisiwe ayinhlanganisela, imibandela ekhona yokwandisa i-stratification ngokuvamile isebenzisa ukuqina kokuphuka kwe-interlaminar okungaguquki njengepharamitha yokusebenza eyisisekelo.[10], ngokuqhathanisa izinga lokukhululwa kwamandla we-crack tip kanye nokuqina kokuphuka kwe-interlaminar. Usayizi wokunquma ukuthi isendlalelo siyakhula yini. Indlela yokuhluleka yama-multi-directional laminates iyinkimbinkimbi[11,12], ebonakala ngamajika abalulekile okumelana no-R[5,13]. Imibandela ekhona yokwandisa enezingqimba ayisinaki lesi sici futhi ayisebenzi ekulingiseni ukuziphatha kwe-delamination kwamabhuloho aqukethe i-fiber multidirectional laminates. Gong et al.[10, 13]ithuthukise indlela yokunweba ekhona ye-stratified futhi ihlongozwe ukwethula ijika lokumelana no-R kunqubo yokunquma, futhi ngokusekelwe kulokhu, kwasungula umbandela wokwandisa we-stratified uma kucatshangelwa imiphumela ye-fiber bridging. Incazelo nokusetshenziswa kwamapharamitha weyunithi ehlangene ehlanganisa kabili iye yacutshungulwa ngokuhlelekile ngezindlela zezinombolo, okuhlanganisa ukuqina kwesixhumi esibonakalayo sokuqala, amandla esixhumi esibonakalayo, i-viscosity coefficient kanye nenani elincane lezinto endaweni yamandla ahlangene. Imodeli yepharamitha yeyunithi ehambisanayo yasungulwa. Okokugcina, ukusebenza kahle nokusebenziseka kwesimo sokunwetshwa esithuthukisiwe esinezingqimba kanye nemodeli yepharamitha yeyunithi ehlangene kuqinisekiswa ukuhlolwa kwe-stratification okumile. Kodwa-ke, indlela yokunquma ethuthukisiwe ingasetshenziswa kuphela ekulingiseni okunengqimba yohlangothi olulodwa ngenxa yokuncika kwendawo futhi hhayi ekwandisweni kwe-hierarchical enezinhlangothi ezimbili noma ezintathu. Ukuze kuxazululwe le nkinga, umlobi uphinde wahlongoza ukuthi kube ne-trilinear cohesive force entsha ecubungula i-fiber bridging.[14]. Ubudlelwano bokusungula bufanelana nenqubo eyinkimbinkimbi yokunwetshwa kwezendlalelo kusuka kumbono we-microscopic, futhi kunezinzuzo zamapharamitha alula nencazelo ecacile yomzimba.

Ukwengeza, ukuze silingise ngokunembile isenzakalo sokufuduka kwe-stratified esivamile enqubweni ye-stratification yama-laminates anezindlela eziningi.[11,12], Zhao et al.[11,12]ihlongoze imodeli yokuqondisa kwendlela yokuqhekeka esekelwe kusici esilinganiselwe esinwetshiwe, elingisa umklamo okhethekile. Ukufuduka kwe-Hierarchical kuhlolo lwe-stratification eyinhlanganisela. Ngesikhathi esifanayo, imodeli yokunweba enezingqimba ihlongozwa ukuziphatha okunwetshiwe kwezendlalelo ezimazombezombe eduze nesixhumi esibonakalayo esinezendlalelo esingu-90°/90°, esilingisa ngokunembile ukuziphatha okunwetshiwe kwesikhombi esibonakalayo esingu-90°/90°.

Umfanekiso 4 Ukulingisa kwezinombolo kokufuduka kwezendlalelo nemiphumela yokuhlola[15]

Umfanekiso 4 Ukulingisa kwezinombolo kokufuduka kwezendlalelo nemiphumela yokuhlola[15]

Isiphetho

Leli phepha ligxile emiphumeleni yocwaningo yaleli qembu emkhakheni we-composite laminate delamination. Izici zokuhlola ikakhulukazi zifaka umthelela we-engeli yokubeka isixhumi esibonakalayo kanye nebhuloho lefayibha ekuziphatheni okunwetshiwe kwe-delamination okumile nokukhathala. Ngokusebenzisa inani elikhulu lezifundo zokuhlola, kutholakala ukuthi indlela yokwehluleka kwe-laminate ye-multi-directional yezinto ezihlanganisiwe iyinkimbinkimbi. I-Fiber bridging iyindlela evamile yokuqinisa ama-laminates anezindlela eziningi, okuyisizathu esiyinhloko sejika elimelana no-R lokuqina kokuphuka kwe-interlaminar. Njengamanje, ucwaningo lwe-R resistance curve ngaphansi kwe-II stratification alukho futhi ludinga olunye ucwaningo. Kusukela kumshini wokuhluleka, kuhlongozwa imodeli yokwahlukanisa ukukhathala okuhlanganisa izici ezihlukahlukene ezithonyayo, okuwumhlahlandlela wocwaningo lokuhlungwa kokukhathala. Ngokuphathelene nokulingiswa kwezinombolo, iqembu locwaningo liphakamise umbandela wokunwetshwa kwesigaba esithuthukisiwe kanye nemodeli yokuhlanganisa ehlangene ukuze kucatshangelwe umthelela we-fiber bridging ekuziphatheni okunwetshiwe okuhlukanisiwe. Ngaphezu kwalokho, i-elementi enwetshiwe enomkhawulo isetshenziselwa ukulingisa kangcono i-hierarchical migration phenomenon. Le ndlela iqeda isidingo sokuhlukaniswa kwamaseli amahle, iqede izinkinga ezihambisana nokuhlukaniswa kabusha kwe-mesh. Inezinzuzo eziyingqayizivele ekulingiseni ukuhlukaniswa komumo okungenasisekelo, futhi ucwaningo olwengeziwe lwesicelo sobunjiniyela lwale ndlela luyadingeka esikhathini esizayo.[16].

Izithenjwa

[1] Y Gong, L Zhao, J Zhang, N Hu. Imodeli yenoveli yokunquma ukumelana nokukhathala kwe-delamination kuma-laminates ayinhlanganisela ngokombono wamandla. I-Compos Sci Technol 2018; 167: 489-96.

[2] L Zhao, Y Wang, J Zhang, Y Gong, N Hu, N Li. Imodeli esekelwe ku-XFEM yokulingisa ukukhula kwe-zigzag delamination kuzinhlanganisela ezinalayini ngaphansi kokulayisha kwemodi I. I-Compos Struct 2017; 160: 1155-62.

[3] L Zhao, Y Gong, J Zhang, Y Wang, Z Lu, L Peng, N Hu. Ukuchazwa kwenoveli kokuziphatha kokukhathala kwe-delamination ukukhula kuma-CFRP ama-multidirectional laminates. I-Compos Sci Technol 2016; 133:79-88.

[4] L Peng, J Zhang, L Zhao, R Bao, H Yang, B Fei. Ukukhula kwe-Mode I kwe-delamination kwama-laminates ahlanganisiwe e-multidirectional ngaphansi kokulayisha ukukhathala. J Compos Mater 2011; 45: 1077-90.

[5] L Zhao, Y Wang, J Zhang, Y Gong, Z Lu, N Hu, J Xu. Imodeli encike esibonakalayo yokuqina kokuqhekeka kwethafa kuma-CFRP ama-multidirectional laminates ngaphansi kokulayisha kwemodi I. Izinhlanganisela Ingxenye B: Ubunjiniyela 2017; 131: 196-208.

[6] L Zhao, Y Gong, J Zhang, Y Chen, B Fei. Ukulingisa ukukhula kwe-delamination kuma-multidirectional laminates ngaphansi kwemodi I kanye nokulayisha kwemodi exubile ye-I/II kusetshenziswa izakhi ezihlangene. I-Compos Struct 2014; 116: 509-22.

[7] Y Gong, B Zhang, L Zhao, J Zhang, N Hu, C Zhang. Ukuziphatha kwe-R-curve yemodi exubile ye-I/II delamination ku-carbon/epoxy laminates ene-interfaces engaqondile kanye ne-multidirectional. I-Compos Struct 2019. (Iyabuyekezwa).

[8] L Peng, J Xu, J Zhang, L Zhao. Imodi ehlanganisiwe yokukhula kwe-delamination ye-multidirectional composite laminates ngaphansi kokulayisha ukukhathala. I-Eng Fract Mech 2012; 96: 676-86.

[9] J Zhang, L Peng, L Zhao, B Fei. Amazinga okukhula kwe-delamination yokukhathala kanye nemikhawulo yama-laminates ayinhlanganisela ngaphansi kokulayisha kwemodi exubile. Int J Ukukhathala 2012; 40:7-15.

[10] Y Gong, L Zhao, J Zhang, Y Wang, N Hu. Umbandela wokusabalalisa i-Delamination ohlanganisa umphumela we-fiber bridging yemodi exubile ye-I/II delamination kuma-CFRP multidirectional laminates. I-Compos Sci Technol 2017; 151: 302-9.

[11] Y Gong, B Zhang, SR Hallett. Ukufuduka kwe-Delamination kuma-multidirectional composite laminates ngaphansi kwemodi ye-quasi-static kanye nokulayishwa kokukhathala. I-Compos Struct 2018; 189: 160-76.

[12] Y Gong, B Zhang, S Mukhopadhyay, SR Hallett. Ucwaningo lokuhlola lokufuduka kwe-delamination kuma-multidirectional laminates ngaphansi kwemodi II static nokulayishwa kokukhathala, ngokuqhathanisa nemodi I. I-Compos Struct 2018; 201: 683-98.

[13] Y Gong, L Zhao, J Zhang, N Hu. Umgomo othuthukisiwe womthetho wamandla wokusakazeka kwe-delamination nomthelela we-fiber bridging enkulu kuma-laminates ayinhlanganisela ye-multidirectional. I-Compos Struct 2018; 184: 961-8.

[14] Y Gong, Y Hou, L Zhao, W Li, G Yang, J Zhang, N Hu. Imodeli yezoni ehlangene yemigqa emithathu yenoveli yokukhula kwe-delamination ku-DCB laminates nomthelela we-fiber bridging. I-Compos Struct 2019. (Izothunyelwa)

[15] L Zhao, J Zhi, J Zhang, Z Liu, N Hu. Ukulingiswa kwe-XFEM kwe-delamination kuma-laminates ayinhlanganisela. Inhlanganisela Ingxenye A: Isayensi Esetshenziswayo Nokukhiqiza 2016; 80: 61-71.

[16] Zhao Libin, Gong Yu, Zhang Jianyu. Inqubekelaphambili yocwaningo mayelana nokuziphatha okunwetshiwe kwe-stratified yama-fiber reinforced composite laminates. Ijenali ye-Aeronautical Sciences 2019: 1-28.

Umthombo:U-Gong Yu, u-Wang Yana, u-Peng Lei, u-Zhao Libin, u-Zhang Jianyu.Ucwaningo mayelana nokuziphatha okunwetshiwe kwe-stratified kwama-laminates ayinhlanganisela ye-carbon fibre ethuthukisiwe[C]. I-Mechanics and Engineering - I-Numerical Computation and Data Analysis 2019 Academic Conference. I-Chinese Society of Mechanics, i-Beijing Mechanics Society, 2019. nge ixueshu

Isikhathi sokuthumela: Nov-15-2019