Makaanikada iyo Injineerinka - Xisaabinta Tirooyinka iyo Falanqaynta Xogta

Makaanikada iyo Injineerinka - Xisaabinta Tirooyinka iyo Falanqaynta Xogta 2019 Shirka Waxbarashada, Abriil 19-21, 2019, Beijing

Abriil 19-21, 2019, Beijing, Shiinaha

Daraasad ku Saabsan Habdhaqan Balaadhinta Lakabsan ee Xashiishka Fiber-Kaarboon ee Sare ee La-xoojiyey ee Xashiishka

Gong Yu1*, Wang Yana2, Peng Lei3, Zhao Libin4, Zhang Jianyu1

1Jaamacadda Chongqing, Chongqing, 400044, Shiinaha

2Machadka Cilmi-baarista Duulimaadyada Shiinaha ee Machadka Cilmi-baarista Qalabka Aeronautical Beijing, Beijing, 100095, Shiinaha

3Diyaaradda Ganacsiga Shiinaha Xarunta Cilmi-baarista Tiknoolajiyada Diyaaradaha Rayidka ee Beijing, Beijing, 102211, Shiinaha

4Jaamacadda Beijing ee Aeronautics iyo Astronautics, Beijing, 100191, Shiinaha

AbstractQaab dhismeedka laminateerku waa mid ka mid ah qaabaynta isku-dhafka ah ee inta badan loo isticmaalo isku-dhafka, laakiin delamination waxay noqotaa qaabkeeda fashilka ugu weyn sababtoo ah sifooyinka interlaminar ee daciifka ah. Cilmi-baadhis ku saabsan kala-soocidda lakabyada badan iyo habdhaqanka fidinta ee sida caadiga ah loo isticmaalo ku-dhaqanka injineernimada ayaa had iyo jeer mawduuc kulul u ahayd culimada. Waraaqdan, natiijooyinka cilmi-baarista ee fiber-ka-karboonka ee la xoojiyay delamination-ka isku-dhafka ah ee Jaamacadda Chongqing iyo Jaamacadda Beijing ee Aeronautics iyo Shaybaarka Daalka Astronautics-ka ayaa laga soo saaray laba dhinac oo cilmi-baaris tijaabo ah iyo jilitaanka tirooyinka. Ugu dambeyntii, jihada horumarinta ee goobta ayaa la filayaa.

Erayada FurahaIsku-darka kaarboonka ee la xoojiyay, laminate, delamination, stratification daal

hordhac

Qalabka isku dhafan ayaa leh sifooyin aad u fiican sida xoog gaar ah oo sarreeya iyo qallafsanaan gaar ah, waxaana si weyn loogu isticmaalay hawada sare, tignoolajiyada tamarta, gaadiidka rayidka iyo dhismaha. Inta lagu guda jiro habaynta iyo isticmaalka walxaha isku dhafan, fiilooyinka iyo matrixku waxay mari doonaan heerar kala duwan oo dhaawac ah marka loo eego culeyska. Hababka guuldarada caadiga ah ee lakabyada isku dhafan waxaa ka mid ah burburka dhexda iyo dhaawaca lakabyada dhexdooda. Sababtoo ah la'aanta xoojinta jihada dhumucda, sifooyinka farsamada ee lateral ee laminate waa liidata, iyo burburka delamination waxay u badan tahay inay ku dhacaan culeysyada saameynta dibadda. Dhacdooyinka iyo balaadhinta burburka habaysan waxay u horseedi doontaa hoos u dhac ku yimaada qallafsanaanta qaabdhismeedka iyo xoogga, oo xitaa sababi kara shilal musiibo ah.[1-3]. Sidaa darteed, dhibaatada delamination waxay aad iyo aad uga walaacsan tahay naqshadaynta qaabdhismeedka iyo falanqaynta xoogga ee alaabta isku dhafan, waxaana lagama maarmaan ah in la barto habdhaqanka fidinta lakabka ah ee alaabta isku dhafan.[4].

Cilmi-baaris ku saabsan dabeecadda ballaarinta lakabka ah ee laminate

1. Daraasad tijaabo ah

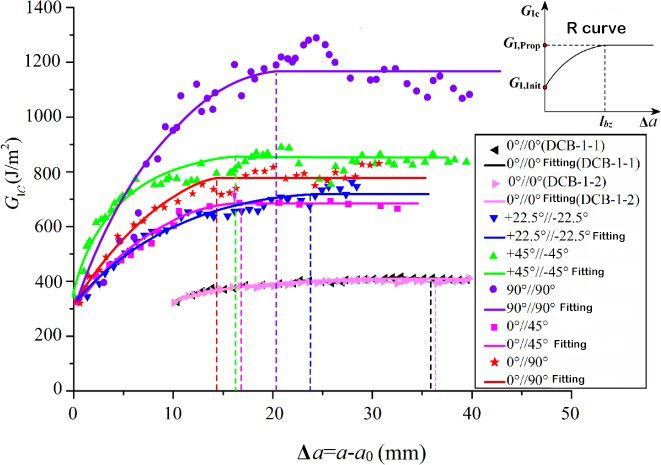

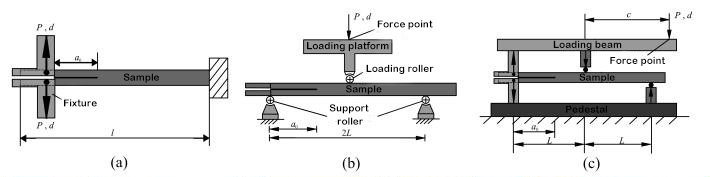

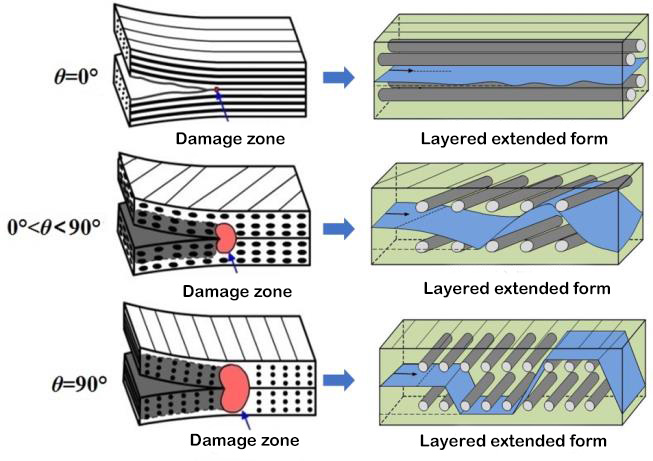

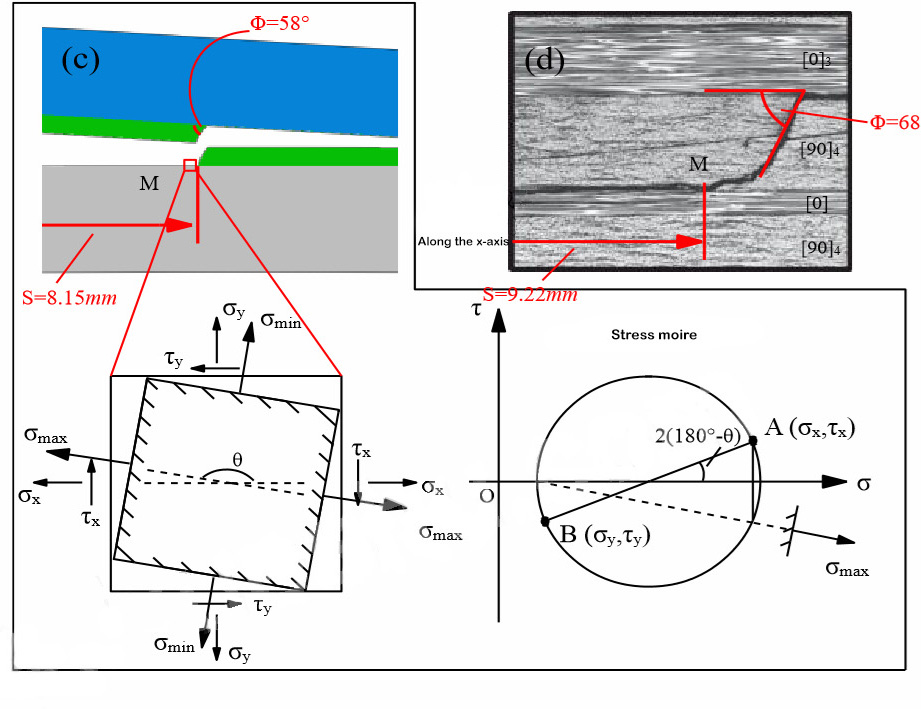

Adkaynta jabka interlaminar waa halbeeg sifada sifooyinka farsamada ee u dhexeeya lakabyada isku dhafan. Heerarka imtixaanka u dhigma ayaa loo dejiyay si loo go'aamiyo adkaanta jabka interlaminar ee Nooca I, Nooca II iyo I/II isku-dhafka ah ee laminates-ka. Qalabka tijaabada ah ee u dhigma ayaa lagu muujiyey Jaantuska 1. Si kastaba ha ahaatee, lakabyada jihooyinka badan ee walxaha isku dhafan ayaa badanaa loo isticmaalaa qaabdhismeedka injineernimada dhabta ah. Sidaa darteed, daraasadda tijaabada ah ee habdhaqanka habaynta iyo fidinta ee laminates-ka jihooyin badan ayaa leh muhiimad aragtiyeed oo muhiim ah iyo qiimaha injineernimada. Bilowga lakabka lakabka badan iyo balaadhinta waxay ka dhex dhacdaa is-dhexgalyada leh xaglo lakabyo aan sabab lahayn, iyo habdhaqanka fidinta lakabka ahi aad ayuu uga duwan yahay kan lakabyada aan jiho lahayn, habka fidinta ayaa aad u dhib badan. Cilmi-baadhayaashu waxay leeyihiin daraasado tijaabo ah oo yar oo ku saabsan laminates-jihooyin badan, iyo go'aaminta adkaanta jabka interlaminar weli ma aasaasin heer caalami ah. Kooxda cilmi-baaristu waxay adeegsadeen T700 iyo T800 fiber carbon si ay u naqshadeeyaan noocyo kala duwan oo laminates isku dhafan oo leh xaglo is-dhexgal oo kala duwan, waxayna daraasad ku sameeyeen saameynta xagasha dul-saarista interface iyo isku-xidhka fiber-ka ee dabeecadda delamination ee joogtada ah iyo daalka. Waxaa la ogaaday in isku-xidhka fiber-ka ee uu sameeyay cidhifka daba-galka ah ee lakabku uu saameyn weyn ku yeesho adkaanta dillaaca interlaminar. Marka shaandheyntu ay balaadhiso, adkaanta jabka interlaminar ayaa si tartiib tartiib ah uga kordheysa qiimaha bilowga ah ee hoose, iyo marka stratification-ku gaaro dherer gaar ah, waxay gaartaa qiime deggan, taas oo ah, ifafaale qalooca iska caabinta R. Adkaynta jabka bilawga ah ee interlayerku waa ku dhawaad siman yahay oo qiyaastii waxay la mid tahay adkaanta jabka resinka, taas oo ku xidhan jabka adkaanta shaxanka laftiisa.[5, 6]. Si kastaba ha noqotee, qiyamka fidinta adkaanta jabka interlaminar ee is-dhexgalka kala duwan ayaa aad u kala duwan. Ku-tiirsanaanta xagasha lakabka is-dhexgalka ee muhiimka ah ayaa la soo bandhigay. Iyadoo laga jawaabayo ku-tiirsanaantan, Zhao et al.[5]oo ku salaysan habka jireed ee isha caabbinta stratified, waxaa loo arkaa in interlaminar jabka adkaanta xasilloonida qiimaha ka kooban yahay laba qaybood, qayb ka mid ah waa shaqada jaban ee interface lakabka aan la xidhiidhin, iyo qaybta kale waa dhaawac intralayer iyo fiber. Shaqada jabka ee ay keento iskudubarid. Iyada oo loo marayo falanqaynta element dhamaadka ah ee goobta hore ee cadaadiska ee hore ee lakabka, waxaa la ogaaday in qaybta labaad ee shaqada jabku ay ku xiran tahay qoto dheer ee aagga dhaawaca hore ee delamination (sida ku cad Jaantuska 3), iyo qoto dheer ee aagga dhaawacu wuxuu u dhigmaa xagasha laydhka interface. Qaabka aragtida ah ee nooca I-jabka jabka qiimaha xasilloonida ee lagu muujiyey shaqada sinusoidal ee xagasha lakabka is-dhexgalka ayaa la soo bandhigay.

Gong iyo al.[7]Waxa la sameeyay tijaabada I/II-ga isku-dhafka ah iyada oo la raacayo saamiyo isku-dhafan oo kala duwan, waxaana la ogaaday in I/II-gaabaynta isku-dhafan ee laminate-ka ay sidoo kale leedahay astaamo qalooca iska caabbinta R oo muhiim ah. Iyada oo la falanqeynayo adkaanta jabka ee u dhexeeya qaybo kala duwan oo tijaabo ah, waxaa la ogaaday in qiimaha bilowga ah iyo qiimaha xasilloon ee adkaanta jajabka interlaminar ee qaybta tijaabada ay si weyn u kordheyso iyadoo la kordhinayo saamiga isku dhafka ah. Intaa waxaa dheer, qallafsanaanta bilawga iyo xasilloonida ee isdhexgalka ee hoos yimaada saamiyo isku dhafan oo kala duwan ayaa lagu qeexi karaa shuruudaha BK.

Marka la eego dhuujinta daalka, isku xidhka fiber-ka ayaa sidoo kale la arkay intii lagu jiray baaritaanka. Iyada oo loo marayo falanqaynta xogta imtixaanka, waxaa la ogaaday in ballaarinta delamination daalka ee walxaha isku dhafan ay saameynayso "qallooca iska caabinta", si markaa qaabka fidinta daalka caadiga ah ee qaabka ballaarinta iyo qiimaha marinka aan la isticmaali karin. Iyada oo ku saleysan falanqaynta aragtida, Zhang iyo Peng[4,8,9]waxay soo bandhigtay caabbinta fidinta delamination daalka si ay u muujiso tamarta looga baahan yahay balaadhinta daalka balaadhinta walxaha isku dhafan, waxayna sii kordhisay soo jeedinta tamarta cadaadiska caadiga ah. Heerka siideynta waa qaabka heerka fidinta daalka ee habaysan iyo qiimaha marinka cabbirrada xakamaynta. Ku-dhaqanka moodeelka iyo cabbirka heerka caadiga ah waxaa lagu xaqiijiyay tijaabooyin. Intaa waxaa dheer, Zhao et al.[3]si guud loo tixgeliyey saamaynta isku-xidhka fiber-ka, saamiga cadaadiska iyo saamiga isku-darka culeyska ee hab-dhaqanka daalka iyo hab-dhaqanka ballaadhinta, waxaana la aasaasay daal caadi ah oo habaysan heerka ballaadhinta iyadoo la tixgelinayo saamaynta saamiga walaaca. Saxnaanta moodeelka waxaa lagu xaqiijiyay tijaabooyinka habaynta daalka oo leh saamiyo walbahaar kala duwan iyo saamiyo isku dhafan. Tirada jireed ee daalka caabbinta balaarineed ee qaabka caadiga ah ee daalku qaabaysan heerka fidinta, Gong et al.[1]ka adkaato daciifnimada habka xisaabinta oo kaliya ku heli kara dhibco xog xaddidan oo xaddidan iyada oo loo marayo tijaabooyin, oo daal ka dhig aragtida tamarta. Qaab falanqeyn ah oo loogu talagalay xisaabinta caabbinta fidsan ee fidsan. Qaabku waxa uu xaqiijin karaa go'aaminta qiyaasta daalka iyo iska caabinta ballaadhinta, oo waxa uu siin karaa taageero aragtiyeed codsiga qaabka heerka fidinta daalka caadiga ah ee la soo jeediyay.

Jaantuska 1 jaantuska qalabka tijaabada

Jaantuska 1 jaantuska qalabka tijaabada

Jaantuska 2 adkaanta jabinta lakabka dhexdooda R qalooca iska caabinta[5]

Jaantuska 3 Aagga dhaawaca geesaha ah ee hogaaminaya iyo qaab-dhismeed fidsan[5]

2. Daraasad jilitaanka tirada

Jilidda tirooyinka ee ballaarinta lakabka ah ayaa ah nuxur cilmi-baaris oo muhiim ah oo ku saabsan qaab-dhismeedka qaabdhismeedka isku dhafan. Marka la saadaalinayo fashilka delamination ee laminates-ka midaysan ee isku dhafan, shuruudaha balaadhinta ee jira waxay caadi ahaan adeegsadaan adkaanta jabka interlaminar joogto ah sida cabbirka waxqabadka aasaasiga ah.[10], iyadoo la is barbardhigayo heerka sii daynta tamarta caarada dildilaaca iyo adkaanta jabka interlaminar. Cabbirka si loo go'aamiyo haddii lakabku sii fidayo. Habka fashilka ee lakabyada jihooyinka badan waa mid adag[11,12], kaas oo lagu garto qaloocyada iska caabinta R ee muhiimka ah[5,13]. Shuruudaha ballaarinta lakabka ah ee jira ma tixgalinayaan sifadan oo ma khusayso jilitaanka dabeecadda delamination ee laminates-jiho badan oo isku xiran oo ka kooban fiber-ka. Gong iyo al.[10, 13]waxay hagaajisay shuruudaha balaadhinta habaysan ee jira waxayna soo jeediyeen in lagu soo bandhigo qalooca iska caabbinta R ee shuruudaha, iyadoo taas lagu salaynayo, la sameeyay cabbir balaarineed oo la tixgalinayo saamaynta isku xidhka fiber-ka. Qeexida iyo cabbirrada isticmaalka unugga isku-dhafan ee laba-geesoodka ah ayaa si habaysan loo darsay habab tirooyin ah, oo ay ku jiraan qallafsanaanta is-dhex-galka bilowga ah, awoodda is-dhex-galka, isku-dheellitirka viscosity iyo tirada ugu yar ee curiyeyaasha aagga xoogga wadajirka ah. Qaabka halbeegyada halbeegyada isku xidhan ee u dhigma ayaa la sameeyay. Ugu dambayntii, waxtarka iyo ku dhaqmida heerka ballaadhinta lakabka ah ee la wanaajiyay iyo qaabka halbeegyada halbeegyada isku xidhan waxa lagu caddeeyey tijaabada shaandhaynta taagan. Si kastaba ha ahaatee, shuruudaha la hagaajiyay waxa kaliya loo isticmaali karaa jilitaanka lakabyada hal-geesoodka ah sababtoo ah ku tiirsanaanta booska ee maaha laba-ama saddex-cabbir kordhinta kala sareynta. Si loo xalliyo dhibaatadan, qoraagu waxa uu soo jeediyay in la sameeyo cudud isku-dhafan oo saddex-linear cusub ah oo tixgelinaysa isku xidhka fiber-ka[14]. Xidhiidhka dastuuriga ahi waxa uu ku haboon yahay habka adag ee balaadhinta lakabka ah marka laga eego aragtida yar-yar, waxana uu leeyahay faa'iidooyinka cabbirro fudud iyo macne muuqaal ah oo cad.

Intaa waxaa dheer, si si sax ah loogu ekaysiiyo ifafaale socdaalka stratified ee caadiga ah ee habka stratification ee laminates jihooyin badan[11,12], Zhao iyo al.[11,12]soo jeediyay qaab hanuunin dariiqa dildilaaca oo ku salaysan curiyaha xaddidan ee la fidiyay, isaga oo u ekaysiinaya naqshad gaar ah. Hijrada kala sarraysa ee imtixaan shaandhayn isku dhafan. Isla mar ahaantaana, qaabka balaadhinta lakabka ah ayaa loo soo jeediyay habdhaqanka fidinta lakabka zigzag ee weheliya 90°/90° interface, kaas oo si sax ah u ekaysiinaya habdhaqanka fidinta lakabka ah ee 90°/90° interface.

Jaantuska 4 Jilitaanka tirada ee socdaalka lakabka ah iyo natiijooyinka tijaabada ah[15]

Jaantuska 4 Jilitaanka tirada ee socdaalka lakabka ah iyo natiijooyinka tijaabada ah[15]

Gabagabo

Warqadani waxay diiradda saaraysaa natiijooyinka cilmi-baarista kooxdan ee goobta delamination laminate ee isku dhafan. Dhinacyada tijaabada ah waxaa inta badan ka mid ah saamaynta xagasha isku xidhka isku xidhka iyo isku xidhka fiber-ka ee habdhaqanka fidinta daalka ee taagan. Iyada oo loo marayo tiro badan oo daraasado tijaabo ah, waxaa la ogaaday in habka fashilka laminate ee jihooyinka badan ee alaabta isku dhafan ay adag tahay. Isku xidhka fiberku waa habka adag ee caadiga ah ee laminates jihooyin badan, taas oo ah sababta ugu weyn ee qalooca R-iska caabinta adag ee jabka interlaminar. Waqtigan xaadirka ah, daraasadda qalooca iska caabbinta R ee hoos timaada II stratification waa mid aad u yar oo u baahan cilmi baaris dheeraad ah. Laga bilaabo habka fashilka, qaabka daalka dajinta oo ay ku jiraan arrimo kala duwan oo saameyn leh ayaa la soo jeediyay, taas oo ah jihada cilmi-baarista daalka. Marka la eego jilitaanka nambarada, kooxda cilmi-baadhistu waxay soo jeedisay shuruudo balaadhinta kala sareynta oo la hagaajiyay iyo qaab isku xidhan si loo tixgeliyo saamaynta isku xidhka faybarku ku leeyahay habdhaqanka fidinta habaysan. Intaa waxaa dheer, curiyaha dhamaadka ah ee la fidiyay ayaa loo istcmaalay in si wanaagsan loogu ekaysiiyo ifafaalaha socdaalka kala sareynta. Habkani wuxuu meesha ka saarayaa baahida loo qabo qaybinta unugyada wanaagsan, baabi'inta dhibaatooyinka la xidhiidha dib-u-qaybinta mesh. Waxay leedahay faa'iidooyin gaar ah oo lagu jili karo shaandhaynta qaababka aan sharciga ahayn, iyo cilmi-baaris badan oo injineernimo oo habkan ah ayaa loo baahan yahay mustaqbalka[16].

Tixraacyo

[1] Y Gong, L Zhao, J Zhang, N Hu. Qaab cusub oo lagu go'aaminayo iska caabbinta delamination daalka ee laminates ka kooban marka laga eego dhinaca tamarta. Compos Sci Technol 2018; 167: 489-96.

[2] L Zhao, Y Wang, J Zhang, Y Gong, N Hu, N Li. Qaab-ku-saleysan XFEM oo loogu talagalay jilitaanka korriinka delamination zigzag ee isku-dhafka la dahaadhay ee hoos yimaada qaabka I. Compos Struct 2017; 160: 1155-62.

[3] L Zhao, Y Gong, J Zhang, Y Wang, Z Lu, L Peng, N Hu. Fasiraadda cusub ee dabeecadda koritaanka daalka delamination ee laminates-ka jihooyinka badan ee CFRP. Compos Sci Technol 2016; 133: 79-88.

[4] L Peng, J Zhang, L Zhao, R Bao, H Yang, B Fei. Habka I delamination korriinka isku-dhafka jihooyinka badan ee laminates ee hoos yimaada culeyska daalka. J Compos Mater 2011; 45: 1077-90.

[5] L Zhao, Y Wang, J Zhang, Y Gong, Z Lu, N Hu, J Xu. Nashqada isku xidhka-ku-tiirsan ee adkaanta jabka plateau ee jihooyin badan oo CFRP ah ayaa hoos u dhigaya qaabka I loading. Qaybaha B: Injineerinka 2017; 131: 196-208.

[6] L Zhao, Y Gong, J Zhang, Y Chen, B Fei. Jilidda kobaca delamination ee lakabyada jihooyinka badan ee hoos yimaada qaabka I iyo qaabka isku dhafan ee I/II iyadoo la isticmaalayo walxo isku xiran. Compos Struct 2014; 116: 509-22.

[7] Y Gong, B Zhang, L Zhao, J Zhang, N Hu, C Zhang. Dabeecadda R-curve ee qaabka isku-dhafan ee I/II ee ku jira kaarboon/epoxy laminates oo leh jiho-jiho iyo jiho badan. Compos Struct 2019. (Dib-u-eegis).

[8] L Peng, J Xu, J Zhang, L Zhao. Habka isku-dhafka ah ee delamination koritaanka ee isku-dhafka jihooyinka badan ee laminates ee hoos yimaada culeyska daalka. Eng Fract Mech 2012; 96: 676-86.

[9] J Zhang, L Peng, L Zhao, B Fei. Heerarka kobaca delamination daalka iyo marinnada laminates-ka isku dhafan ee hoos yimaada habka isku dhafan. Int J Daal 2012; 40: 7-15.

[10] Y Gong, L Zhao, J Zhang, Y Wang, N Hu. Shuruudaha faafinta faafinta oo ay ku jirto saamaynta isku-xidhka fiber-ka ee qaabka isku-dhafan ee I/II delamination ee jihooyin badan oo CFRP ah. Compos Sci Technol 2017; 151: 302-9.

[11] Y Gong, B Zhang, SR Hallett. Delamination guuritaanka ee isku-dhafka jihooyinka badan ee laminates ee hoos yimaada qaabka I-ka-joogta ah iyo culeyska daalka. Compos Struct 2018; 189: 160-76.

[12] Y Gong, B Zhang, S Mukhopadhyay, SR Hallett. Daraasad tijaabo ah oo ku saabsan socdaalka delamination ee laminates jihooyin badan oo hoos yimaada habka II static iyo loading daal, marka la barbardhigo qaabka I. Compos Struct 2018; 201: 683-98.

[13] Y Gong, L Zhao, J Zhang, N Hu. Shuruudaha sharciga awooda ee la wanaajiyey ee faafinta delamination oo leh saamaynta isku xidhka fibre ee baaxadda weyn ee laminates-jiho badan oo isku dhafan. Compos Struct 2018; 184: 961-8.

[14] Y Gong, Y Hou, L Zhao, W Li, G Yang, J Zhang, N Hu. Qaab aag iskuxiran oo saddex-linear ah oo cusub oo loogu talagalay kobaca delamination ee DCB waxay ku dhejisaa saamaynta isku xidhka fiber-ka. Compos Struct 2019. (Waa la gudbinayaa)

[15] L Zhao, J Zhi, J Zhang, Z Liu, N Hu. Jilitaanka XFEM ee delamination ee laminates-ka isku dhafan. Isku-dhafka Qaybta A: Sayniska iyo Wax-soo-saarka la dabaqay 2016; 80: 61-71.

[16] Zhao Libin, Gong Yu, Zhang Jianyu. Horumarka cilmi baarista ee habdhaqanka fidinta fidsan ee laminates-ka isku dhafan ee la xoojiyay. Joornaalka Sayniska Hawada 2019: 1-28.

Xigasho:Gong Yu, Wang Yana, Peng Lei, Zhao Libin. Makaanikada iyo Injineerinka - Xisaabinta Tirooyinka iyo Falanqaynta Xogta 2019 Shirka Waxbarashada. Bulshada Makaanikada Shiinaha, Bulshada Makaanikada Beijing, 2019. iyada oo loo marayo ixueshu

Waqtiga boostada: Nov-15-2019