UBUCHWEPHESHE NOBUNJINELI - Ukubalwa kwamanani kunye noHlalutyo lweeNkcukacha

Ubuchwephesha kunye nobuNjineli — Ukubalwa kwamanani kunye noHlalutyo lweDatha ka-2019 kwiNkomfa yeziFundo, ngo-Epreli 19-21, 2019, eBeijing

Ngo-Epreli 19-21, 2019, eBeijing, eTshayina

Uphononongo kwiNdlela yoKwandiswa koMaleko oBuphucukileyo beCarbon Fiber eQinisekisiweyo yePhepha leLaminates

Gong Yu1*, Wang Yana2, Peng Lei3, Zhao Libin4, Zhang Jianyu1

1IYunivesithi yaseChongqing, eChongqing, 400044, China

2Iziko loPhando lwezoPhando lwaseTshayina iBeijing Aeronautical Materials Research Institute, Beijing, 100095, China

3China Commercial Aircraft Beijing Civil Aircraft Technology Research Centre, Beijing, 102211, China

4IYunivesithi yaseBeijing yeAeronautics kunye neAstronautics, eBeijing, ngo-100191, eTshayina

AbstractUlwakhiwo lweLaminate yenye yezona zinto zisetyenziswa ngokuqhelekileyo ulungelelwaniso oludityanisiweyo lokudibanisa, kodwa i-delamination iba yimowudi yokusilela kwayo ngenxa yeempawu ezibuthathaka ze-interlaminar. Uphando malunga ne-multi-laminate stratification kunye nokuziphatha kokwandisa okuqhelekileyo kusetyenziswa kumsebenzi wobunjineli bekusoloko kungumxholo oshushu kubaphengululi. Kweli phepha, iziphumo zophando ze-carbon fiber zomelezwa i-delamination ye-composite kwiYunivesithi yaseChongqing kunye neYunivesithi yaseBeijing ye-Aeronautics kunye ne-Astronautics Fatigue Fracture Laboratory yaziswa ukusuka kwimiba emibini yophando lovavanyo kunye nokulinganisa kwamanani. Ekugqibeleni, ulwalathiso lophuhliso lwentsimi lulindelwe.

Amagama angundoqo:i-carbon fibre eyomeleziweyo edibeneyo, i-laminate, i-delamination, i-stratification yokudinwa

intshayelelo

Iimathiriyeli ezihlanganisiweyo zineempawu ezibalaseleyo njengamandla athile aphezulu kunye nokuqina okuphezulu okuthe ngqo, kwaye zisetyenziswe ngokubanzi kwi-aerospace, itekhnoloji yamandla, kunye nokuthuthwa kwabantu kunye nokwakhiwa. Ngethuba lokucutshungulwa kunye nokusetyenziswa kwezinto ezidibeneyo, iifibers kunye ne-matrix ziya kudlula amanqanaba ahlukeneyo omonakalo phantsi komthwalo. Iindlela zokungaphumeleli eziqhelekileyo ze-laminates ezidibeneyo ziquka umonakalo we-interlayer kunye nomonakalo ngaphakathi kweeleyile. Ngenxa yokunqongophala kokuqiniswa kwinqanaba lobunzima, iimpawu ze-lateral ze-laminate zihluphekile, kwaye umonakalo we-delamination unokwenzeka kakhulu phantsi kwemithwalo yempembelelo yangaphandle. Ukwenzeka kunye nokwandiswa komonakalo odibeneyo kuya kukhokelela ekwehleni kokuqina kwesakhiwo kunye namandla, kwaye kubangele iingozi eziyingozi.[1-3]. Ke ngoko, ingxaki ye-delamination ixhalaba ngakumbi kuyilo lolwakhiwo kunye nohlalutyo lwamandla ezinto ezidibeneyo, kwaye kuyafuneka ukufunda indlela yokwandiswa komgangatho wezinto ezidibeneyo.[4].

Uphando malunga nokuziphatha kokwandiswa kwe-laminate

1. Uphononongo lovavanyo

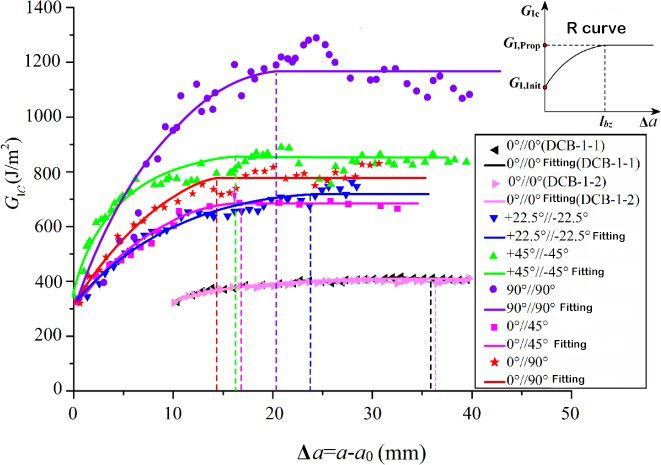

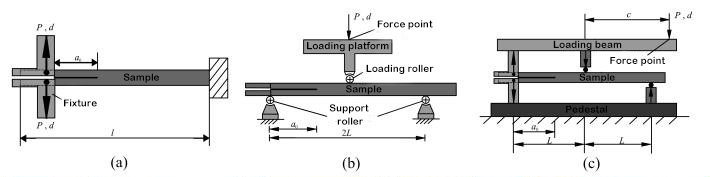

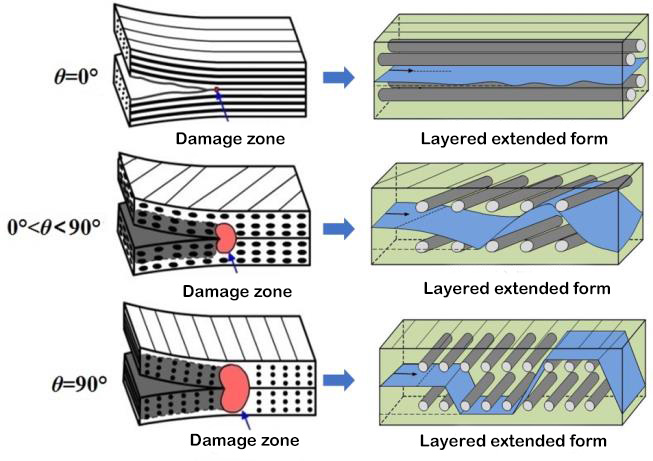

I-Interlaminar fracture toughness yiparameter yeempawu zomatshini phakathi kweeleya ezidibeneyo. Imigangatho yovavanyo ehambelanayo iye yamiselwa ukumiselwa kokuqina kwe-interlaminar fracture yoHlobo lwe-I, Uhlobo lwe-II kunye ne-I / II ye-hybrid unidirectional laminates. Izixhobo zokuvavanya ezihambelanayo ziboniswa kuMfanekiso 1. Nangona kunjalo, i-laminates ye-multi-directional ye-composite materials idla ngokusetyenziswa kwisakhiwo sobunjineli sangempela. Ke ngoko, uphononongo lovavanyo malunga nokwahlulwa kunye nokuziphatha okwandisiweyo kweelaminates ezinamacala amaninzi kunokubaluleka kwethiyori kunye nexabiso lobunjineli. Ukuqaliswa kolwaleko olunemigangatho emininzi kunye nokwandiswa kwenzeka phakathi kojongano oluneengile zomaleko ezingafanelekanga, kwaye indlela yokwandiswa komgangatho wokuziphatha yahluke kakhulu kuleyo yelaminates ze-unidirectional, kwaye indlela yokwandisa inzima ngakumbi. Abaphandi banezifundo ezimbalwa zovavanyo kwiilaminates ezimacala amaninzi, kwaye ukuzimisela kokuqina kwe-interlaminar fracture akukamisela umgangatho wehlabathi. Iqela lophando lisebenzise i-T700 kunye ne-T800 ifayibha yekhabhoni ukuyila iintlobo ngeentlobo zeelaminates ezihlanganisiweyo ezineengile ezahlukeneyo zokubeka ujongano, kwaye yafunda impembelelo ye-angle yokubeka i-interface kunye ne-fiber bridging kwi-static kunye nokuziphatha kokudinwa kwe-delamination. Kuye kwafunyaniswa ukuba i-fiber bridging eyenziwe ngumphetho wokulandela umaleko kunempembelelo enkulu kukuqina kwe-interlaminar fracture. Njengoko i-stratification ikhula, ukuqina kwe-interlaminar fracture kuya kwanda ngokuthe ngcembe ukusuka kwixabiso eliphantsi lokuqala, kwaye xa i-stratification ifikelela kubude obuthile, ifikelela kwixabiso elizinzile, oko kukuthi, i-R resistance curve phenomenon. Ukuqina kokuqala kokwaphuka kwe-interlayer kuphantse kwalingana kwaye kuphantse kulingane nokuqina kokwaphuka kwe-resin, okuxhomekeke kukuqina kokwaphuka kwe-matrix ngokwayo.[5, 6]. Nangona kunjalo, ukuqina kwe-interlaminar fracture amaxabiso onxibelelwano ohlukeneyo ahluka kakhulu. Ukuxhomekeka kwe-engile yojongano olubalulekileyo kubonisiwe. Ukuphendula kolu kuxhomekeka, uZhao et al.[5]ngokusekelwe kwindlela yomzimba yomthombo wokumelana ne-stratified, kucingwa ukuba ixabiso lokuzinza kokuqina kokwaphuka kwe-interlaminar liquka iinxalenye ezimbini, inxalenye enye ngumsebenzi wokuqhekeka kojongano lwamaleko anganxulumananga, kwaye enye inxalenye yomonakalo we-intralayer kunye nefayibha. Umsebenzi wokwaphuka okubangelwa kukubopha ibhulorho. Ngokusebenzisa uhlalutyo element elinganiselweyo intsimi yoxinzelelo lwangaphambili lwe umaleko wangaphambili, kufunyaniswe ukuba inxalenye yesibini yomsebenzi wokwaphuka kuxhomekeke kubunzulu bendawo yomonakalo wangaphambili we-delamination (njengoko kubonisiwe kuMfanekiso 3), kunye nobunzulu bommandla womonakalo ulingana ne-engile yokubeka ujongano. Imodeli yethiyori yohlobo lwe-I-uhlobo lokuqina kokuqina kwexabiso elichazwe ngumsebenzi we-sinusoidal we-angle ye-interface layer ibonisiwe.

Gong et al.[7]luqhube uvavanyo lwe-I/II hybrid stratification phantsi komlinganiselo wokuxutywa ohlukeneyo, kwaye yafumanisa ukuba i-I/II hybrid stratification kwi-laminate nayo ineempawu ezibalulekileyo ze-R zokuxhathisa. Ngokuhlalutya ukuqina kweqhekeza phakathi kweengcezu ezahlukeneyo zokuvavanya, kufunyenwe ukuba ixabiso lokuqala kunye nexabiso elizinzile le-interlaminar fracture toughness ye-piece test piece yanda kakhulu ngokunyuka komlinganiselo wokuxuba. Ukongezelela, ukuqina kokuqala kunye nokuzinza kwe-fracture ye-interlayer phantsi kwemilinganiselo eyahlukeneyo yokuxuba kunokuchazwa ngumlinganiselo we-BK.

Ngokubhekiselele kwi-stratification yokudinwa, i-fiber bridging ebalulekileyo nayo yabonwa ngexesha lovavanyo. Ngokuhlalutya idatha yovavanyo, kufunyenwe ukuba ukudinwa kwe-delamination ukwandiswa kwezinto ezihlanganisiweyo kuchatshazelwa "yi-resistance curve", ukwenzela ukuba imodeli yokwandiswa kwe-stratification yokudinwa kwendabuko kunye nexabiso lomqobo ayisasebenzi. Ngokwesiseko sohlalutyo lwethiyori, uZhang noPeng[4,8,9]yazisa ukudinwa delamination ukwandiswa ukuxhathisa ukuvakalisa amandla afunekayo ekwandiseni ukudinwa delamination kwemathiriyeli edityanisiweyo, kwaye uphakamise ngakumbi amandla oxinzelelo oluqhelekileyo. Izinga lokukhululwa liyimodeli yokudinwa kwe-stratified rate yokwandisa kunye nexabiso lomda weeparamitha zolawulo. Ukusetyenziswa kwemodeli kunye neparameter yesiqhelo yesiqhelo iqinisekiswa yimifuniselo. Ngapha koko, uZhao et al.[3]kuqwalaselwe ngokubanzi iziphumo ze-fiber bridging, umlinganiselo woxinzelelo kunye nomlinganiselo wokuxuba umthwalo ekudinweni koxinzelelo kunye nokuziphatha okwandisiweyo, kwaye kusekwe imodeli yokwandiswa kokudinwa okuqhelekileyo kuthathelwa ingqalelo impembelelo yomlinganiselo woxinzelelo. Ukuchaneka komzekelo kwaqinisekiswa ngovavanyo lwe-stratification yokukhathala kunye nemilinganiselo eyahlukeneyo yoxinzelelo kunye nokuxuba ukuxuba. Ngobungakanani bomzimba wokudinwa okuhambelana nokwandiswa koxhaso kwimodeli eqhelekileyo yokudinwa kwenqanaba lokwandiswa, uGong et al.[1]boyise ubuthathaka bendlela yokubala enokufumana kuphela amanqaku anqongopheleyo edatha ngokusebenzisa imifuniselo, kunye nokuseka ukudinwa ngokwembono yamandla. Imodeli yohlalutyo yokubala ukuchasana okwandisiweyo okwandisiweyo. Imodeli inokuqonda ukumiselwa kobungakanani bokudinwa koxinzelelo kunye nokumelana nokwandiswa, kunye nokubonelela ngenkxaso yethiyori ekusetyenzisweni kwemodeli ecetywayo yokudinwa kwestratified rate yokwandisa.

Isazobe soku-1 somzobo wesixhobo sovavanyo

Isazobe soku-1 somzobo wesixhobo sovavanyo

Umzobo 2 Ubunzima bokuqhekeka kwe-Inter-layer R igophe lokumelana[5]

Umzobo 3 Uluhlu lwendawo yomonakalo ophambili kunye nemopholoji eyandisiweyo[5]

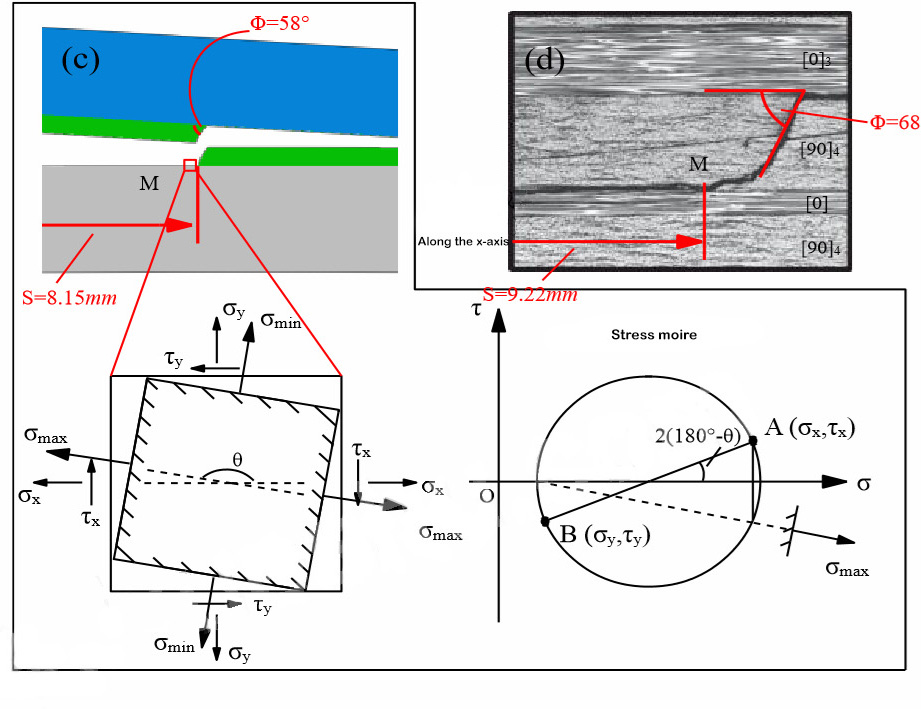

2. Uphononongo lokulinganisa amanani

Ukulinganisa kwamanani kokwandiswa okucwangcisiweyo ngumxholo obalulekileyo wophando kwinkalo yoyilo lwesakhiwo esidibeneyo. Xa kuqikelelwa ukusilela kwe-delamination ye-laminates edibeneyo edibeneyo, imilinganiselo ekhoyo yokwandiswa kwe-stratification idla ngokusebenzisa ukuqina kokwaphuka kwe-interlaminar njengesiseko separameter yokusebenza.[10], ngokuthelekisa umyinge wokukhupha amandla we-crack tip kunye nokuqina kwe-interlaminar fracture. Ubungakanani bokumisela ukuba umaleko uyakhula. Indlela yokungaphumeleli ye-laminates ye-multi-directional iyinkimbinkimbi[11,12], ebonakaliswa ngamagophe okumelana ne-R abalulekileyo[5,13]. Iikhrayitheriya zolwandiso olukhoyo olukhoyo aluthatheli ngqalelo olu phawu kwaye alusebenzi kukulinganisa ukuziphatha kwe-delamination ye-fiber-containing bridged multidirectional laminates. Gong et al.[10, 13]iphuculwe indlela ekhoyo yokwandiswa kwe-stratified stratified kwaye indululwe ukwazisa i-R resistance curve kwiikhrayitheriya, kwaye isekelwe koku, yaseka inqobo yokwandiswa kwe-stratified ngokuqwalasela imiphumo ye-fiber bridging. Inkcazo kunye nokusetyenziswa kweeparameters zeyunithi ye-bililinear constitutive cohesive unit yafundwa ngokucwangcisiweyo ngeendlela zamanani, kubandakanywa ukuqina kwe-interface yokuqala, amandla okudibanisa, i-viscosity coefficient kunye nenani elincinci lezinto kwi-cohesive force zone. Imodeli yeparamitha yeyunithi ehambelanayo yasekwa. Okokugqibela, ukusebenza kunye nokusetyenziswa kwekhrayitheriya ephuculweyo yolwandiso kunye nemodeli yeparamitha edibeneyo yeyunithi iqinisekiswa luvavanyo lwe-static stratification. Nangona kunjalo, iinqobo zokugweba eziphuculweyo zingasetyenziselwa kuphela ukulinganisa okunomgangatho omnye ngenxa yokuxhomekeka kwendawo kwaye hayi ekwandisweni kwemigangatho emibini okanye emithathu-ntathu. Ukuze kusonjululwe le ngxaki, umbhali uqhubele phambili ecebise ukuba kusetyenziswe amandla amatsha obumbano obuthathu obuthathela ingqalelo ukudibanisa ifayibha.[14]. Ubudlelwane obubambekayo buhambelana nenkqubo entsonkothileyo yolwandiso olunamaleko ukusuka kumbono we-microscopic, kwaye lunoncedo lweeparamitha ezilula kunye nentsingiselo ebonakalayo ebonakalayo.

Ukongeza, ukwenzela ukulinganisa ngokuchanekileyo isiganeko sokufuduka kwe-stratified eqhelekileyo kwinkqubo yokuhlelwa kweelaminates ezininzi.[11,12], Zhao et al.[11,12]icetywayo imodeli yesikhokelo sendlela yokuqhekeka esekwe kwisiqalelo esongeziweyo esinomda, silinganisa uyilo olulodwa. Ukufuduka kwe-Hierarchical kuvavanyo lwe-stratification edibeneyo. Kwangaxeshanye, imodeli yolwandiso olunamaleko lucetywayo kwindlela yokwandiswa komgangatho we-zigzag ecaleni kwe-90 °/90 ° ujongano olunamaleko, olulinganisa ngokuchanekileyo indlela yokwandiswa komgangatho we-90 °/90 ° ujongano.

Umzobo we-4 Ukulinganisa kwamanani okufuduka okucwangcisiweyo kunye neziphumo zovavanyo[15]

Umzobo we-4 Ukulinganisa kwamanani okufuduka okucwangcisiweyo kunye neziphumo zovavanyo[15]

Ukuqukumbela

Eli phepha lijolise kwiziphumo zophando zeli qela kwintsimi ye-composite laminate delamination. Imiba yovavanyo ikakhulu ibandakanya impembelelo ye-engile yokubeka i-engile kunye ne-fiber bridging kwi-static kunye nokudinwa kwe-delamination yokuziphatha. Ngokusebenzisa inani elikhulu lezifundo zovavanyo, kufunyenwe ukuba indlela yokungaphumeleli kwe-laminate multi-directional yezinto ezidibeneyo inzima. I-Fiber bridging yindlela eqhelekileyo yokuqinisa i-laminates ye-multi-directional, esona sizathu siphambili se-R-resistance curve ye-interlaminar fracture toughness. Okwangoku, uphando lwe-R resistance curve phantsi kwe-II stratification alukho kwaye lufuna uphando olongezelelweyo. Ukuqala kwindlela yokungaphumeleli, imodeli yokudinwa kwe-stratification equka izinto ezahlukeneyo ezinempembelelo iyacetywa, nto leyo isalathiso sophando lwe-stratification yokudinwa. Ngokumalunga nokulinganisa kwamanani, iqela lophando licebise inqobo yokwandiswa kwe-hierarchical ephuculweyo kunye nemodeli edibeneyo edibeneyo yokuqwalasela impembelelo ye-fiber bridging kwindlela yokuziphatha yokwandisa. Ukongeza, i-elementi eyandisiweyo enomda isetyenziselwa ukulinganisa ngcono i-hierarchical migration phenomenon. Le ndlela iphelisa imfuno yokwahlulahlula kakuhle kweeseli, ukuphelisa iingxaki ezinxulumene nokwahlulahlulwa kwakhona komnatha. Ineengenelo ezizodwa ekulinganiseni ukucwangciswa kweemilo ezingafanelekanga, kunye nophando olungakumbi lwesicelo sobunjineli sale ndlela iyafuneka kwixesha elizayo.[16].

Iimbekiselo

[1] Y Gong, L Zhao, J Zhang, N Hu. Imodeli yenoveli yokumisela ukudinwa kwe-delamination ukuxhathisa kwii-laminates ezihlanganisiweyo ngokwembono yamandla. I-Compos Sci Technol 2018; 167: 489-96.

[2] L Zhao, Y Wang, J Zhang, Y Gong, N Hu, N Li. Imodeli esekwe kwi-XFEM yokulinganisa ukukhula kwe-zigzag delamination kwiicomposites elaminethiweyo phantsi kwemowudi yokulayisha. Umgaqo weCompos 2017; 160: 1155-62.

[3] L Zhao, Y Gong, J Zhang, Y Wang, Z Lu, L Peng, N Hu. Utoliko lwenoveli yokudinwa delamination ukukhula ukuziphatha kwiCFRP multidirectional laminates. I-Compos Sci Technol 2016; 133: 79-88.

[4] L Peng, J Zhang, L Zhao, R Bao, H Yang, B Fei. Imowudi yokukhula kwe-delamination ye-multidirectional composite laminates phantsi kokulayisha ukukhathala. J Compos Mater 2011; 45: 1077-90.

[5] L Zhao, Y Wang, J Zhang, Y Gong, Z Lu, N Hu, J Xu. Imodeli exhomekeke kujongano lweplateau fracture toughness in multidirectional CFRP laminates under mode I loading. I-Composites Icandelo B: Ubunjineli be-2017; 131: 196-208.

[6] L Zhao, Y Gong, J Zhang, Y Chen, B Fei. Ukulinganisa ukukhula kwe-delamination kwi-multidirectional laminates phantsi kwemodi ye-I kunye nemodi edibeneyo yokulayishwa kwe-I / II usebenzisa izinto ezidibeneyo. Umthetho weCompos 2014; 116: 509-22.

[7] Y Gong, B Zhang, L Zhao, J Zhang, N Hu, C Zhang. Ukuziphatha kwe-R-curve ye-mixed-mode ye-I / II delamination kwi-carbon / epoxy laminates kunye ne-interfaces ye-unidirectional kunye ne-multidirectional. I-Compos Struct 2019. (Phantsi koPhononongo).

[8] L Peng, J Xu, J Zhang, L Zhao. Imodi edibeneyo yokukhula kwe-delamination ye-multidirectional composite laminates phantsi kokulayisha ukukhathala. Eng Fract Mech 2012; 96: 676-86.

[9] J Zhang, L Peng, L Zhao, B Fei. Amazinga okukhula okudinwa kwe-delamination kunye nemigubasi ye-laminates edibeneyo phantsi kokulayisha imodi edibeneyo. Int J Ukukhathala 2012; 40: 7-15 .

[10] Y Gong, L Zhao, J Zhang, Y Wang, N Hu. I-Delamination propagation criterion iquka ifuthe le-fiber bridging ye-mixed-mode I/II delamination in CFRP multidirectional laminates. ICompos Sci Technol 2017; 151: 302-9.

[11] Y Gong, B Zhang, SR Hallett. Ukufuduka kwe-Delamination kwi-multidirectional composite laminates phantsi kwemowudi ye-quasi-static kunye nokulayisha ukukhathala. Umgaqo weCompos 2018; 189: 160-76.

[12] Y Gong, B Zhang, S Mukhopadhyay, SR Hallett. Uphononongo lovavanyo lokufuduka kwe-delamination kwi-multidirectional laminates phantsi kwemowudi ye-II static kunye nokulayisha ukukhathala, ngokuthelekisa kwimodi ye-I. I-Compos Struct 2018; 201: 683-98.

[13] Y Gong, L Zhao, J Zhang, N Hu. Uphuculo lwenqobo yomthetho wamandla wokusasazwa kwe-delamination kunye nefuthe le-fiber bridging enkulu kwi-laminates ehlanganisiweyo ye-multidirectional. Umgaqo weCompos 2018; 184: 961-8.

[14] Y Gong, Y Hou, L Zhao, W Li, G Yang, J Zhang, N Hu. Imodeli yezowuni edibeneyo enemigca emithathu yenoveli yokukhula kwe-delamination kwi-DCB laminates kunye nefuthe le-fiber bridging. Umgaqo weCompos 2019. (Iya kufakwa)

[15] L Zhao, J Zhi, J Zhang, Z Liu, N Hu. Ukulinganisa kwe-XFEM kwe-delamination kwii-laminates ezidibeneyo. I-Composites iCandelo A: iSayensi eSetyenzisiweyo kunye neMveliso 2016; 80: 61-71.

[16] Zhao Libin, Gong Yu, Zhang Jianyu. Inkqubela phambili yophando malunga nokuziphatha kokwandiswa kwe-stratified fiber reinforced composite laminates. Ijenali yeNzululwazi yezobuNzululwazi ngo-2019: 1-28.

Umthombo:UGong Yu, uWang Yana, uPeng Lei, uZhao Libin, uZhang Jianyu.Uphononongo malunga nokuziphatha okwandisiweyo okucwangcisiweyo kweelaminates ezihlanganisiweyo zekhabhoni [C]. I-Mechanics kunye nobuNjineli - i-Numercal Computation kunye noHlalutyo lweDatha ye-2019 yeNkomfa yezeMfundo. Umbutho wamaTshayina woomatshini, uMbutho woomatshini baseBeijing, ngo-2019. nge ixueshu

Ixesha lokuposa: Nov-15-2019