MECHANICS THIAB ENGINEERING - Kev suav lej thiab kev txheeb xyuas cov ntaub ntawv

Mechanics thiab Engineering - Kev suav lej thiab Kev Ntsuas Cov Ntaub Ntawv 2019 Kev Sib Tham Kev Kawm, Plaub Hlis 19-21, 2019, Beijing

Lub Plaub Hlis 19-21, 2019, Beijing, Suav

Kawm txog Cov Txheej Txheem Kev nthuav dav ntawm Advanced Carbon Fiber Reinforced Composite Laminates Sheet

Gong Yu1*, Wang Yana2, Peng Li3, Zhao Libin4, Zhang Jianyu1

1Chongqing University, Chongqing, 400044, Suav

2Tuam Tshoj Aviation Research Institute Beijing Aeronautical Materials Research Institute, Beijing, 100095, Suav

3Tuam Tshoj Commercial Aircraft Beijing Civil Aircraft Technology Research Center, Beijing, 102211, Suav

4Beijing University of Aeronautics thiab Astronautics, Beijing, 100191, Suav

AbstractLaminate qauv yog ib qho ntawm feem ntau siv cov kev teeb tsa sib xyaw rau cov khoom sib xyaw, tab sis delamination dhau los ua nws hom kev ua tsis tiav vim tsis muaj zog interlaminar zog. Kev tshawb fawb ntawm ntau txheej txheej laminate stratification thiab nthuav dav tus cwj pwm uas nquag siv hauv engineering xyaum yeej ib txwm yog lub ntsiab lus kub rau cov kws tshawb fawb. Hauv daim ntawv no, kev tshawb fawb cov txiaj ntsig ntawm carbon fiber reinforced composite delamination nyob rau hauv Chongqing University thiab Beijing University of Aeronautics thiab Astronautics Fatigue Fracture Laboratory yog qhia los ntawm ob yam ntawm kev sim kev tshawb fawb thiab cov lej simulation. Thaum kawg, txoj kev loj hlob ntawm lub teb yog prospected.

Ntsiab lus:carbon fiber reinforced composite, laminate, delamination, qaug zog stratification

kev taw qhia

Cov ntaub ntawv sib xyaw muaj cov khoom zoo xws li lub zog tshwj xeeb thiab muaj zog tshwj xeeb, thiab tau siv dav hauv aerospace, hluav taws xob thev naus laus zis, thiab kev thauj mus los hauv pej xeem thiab kev tsim kho. Thaum lub sij hawm ua thiab siv cov ntaub ntawv sib xyaw, cov fibers thiab matrix yuav dhau mus rau qhov sib txawv ntawm kev puas tsuaj nyob rau hauv load. Hom tsis ua haujlwm feem ntau rau cov laminates sib xyaw suav nrog kev puas tsuaj ntawm cov txheej txheem thiab kev puas tsuaj hauv cov txheej. Vim tias tsis muaj kev txhawb nqa hauv cov kev taw qhia tuab, lub lateral mechanical zog ntawm lub laminate tsis zoo, thiab kev puas tsuaj delamination yuav tshwm sim nyob rau hauv kev cuam tshuam sab nraud. Qhov tshwm sim thiab nthuav dav ntawm kev puas tsuaj stratified yuav ua rau txo qis ntawm cov txheej txheem rigidity thiab lub zog, thiab txawm ua rau muaj kev puas tsuaj loj.[1-3]. Yog li ntawd, qhov teeb meem delamination yog ntau thiab muaj kev txhawj xeeb los ntawm cov qauv tsim thiab kev tsom xam lub zog ntawm cov ntaub ntawv sib xyaw, thiab nws yuav tsum tau kawm txog cov txheej txheem nthuav dav ntawm cov khoom sib xyaw.[4].

Kev tshawb fawb txog txheej txheem nthuav dav ntawm laminate

1. Kev sim kawm

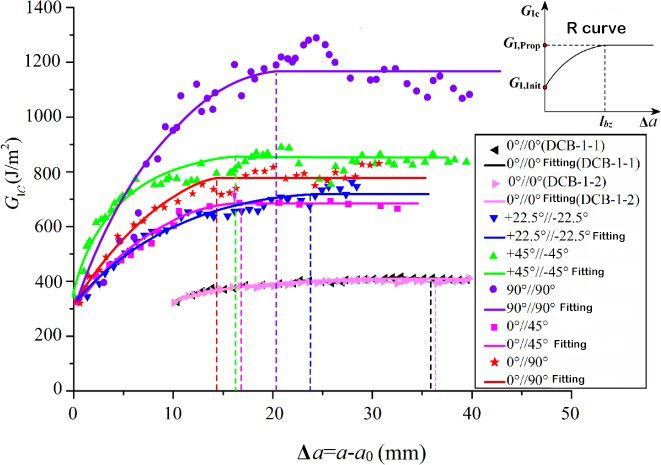

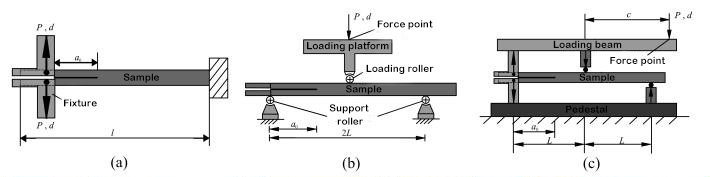

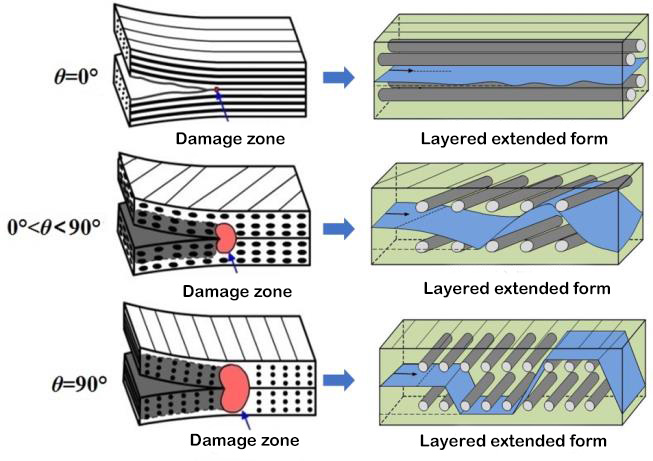

Interlaminar fracture toughness yog ib tug yam ntxwv parameter ntawm mechanical zog ntawm cov txheej txheem. Cov qauv ntsuas sib raug tau tsim los rau kev txiav txim siab ntawm interlaminar tawg toughness ntawm Hom I, Hom II thiab I / II hybrid unidirectional laminates. Cov cuab yeej ntsuas sib txuas tau pom nyob rau hauv daim duab 1. Txawm li cas los xij, cov laminates multi-directional laminates ntawm cov ntaub ntawv sib xyaw feem ntau yog siv rau hauv cov qauv engineering tiag tiag. Yog li ntawd, kev sim kev tshawb fawb txog kev stratification thiab nthuav tus cwj pwm ntawm ntau cov kev taw qhia laminates muaj ntau qhov tseem ceeb theoretical tseem ceeb thiab tus nqi engineering. Multi-layer laminate txheej pib thiab nthuav dav tshwm sim ntawm kev cuam tshuam nrog cov txheej txheem txheej txheej, thiab cov txheej txheem nthuav dav yog qhov sib txawv ntawm cov laminates unidirectional, thiab cov txheej txheem nthuav dav yog qhov nyuaj. Cov kws tshawb fawb muaj qee qhov kev sim kev tshawb fawb ntawm ntau cov kev taw qhia laminates, thiab kev txiav txim siab ntawm interlaminar tawg toughness tseem tsis tau tsim ib qho qauv thoob ntiaj teb. Pab neeg tshawb fawb tau siv T700 thiab T800 carbon fiber los tsim ntau yam kev sib xyaw laminates nrog sib txawv interface layup kaum sab xis, thiab kawm txog kev cuam tshuam ntawm lub kaum sab xis thiab fiber ntau txuas rau ntawm tus cwj pwm zoo li qub thiab qaug zog delamination. Nws tau raug pom tias fiber ntau bridging tsim los ntawm ntug ntawm txheej txheej muaj kev cuam tshuam zoo rau ntawm interlaminar tawg toughness. Raws li cov stratification nthuav dav, lub interlaminar tawg toughness yuav maj mam nce los ntawm tus nqi pib qis, thiab thaum lub stratification ncav cuag ib tug ntev, nws mus txog ib tug ruaj khov tus nqi, uas yog, R-resistant nkhaus tshwm sim. Thawj pob txha toughness ntawm lub interlayer yog yuav luag sib npaug thiab kwv yees li sib npaug ntawm cov pob txha toughness ntawm cov cob, uas nyob ntawm qhov tawg toughness ntawm matrix nws tus kheej.[5, 6]. Txawm li cas los xij, lub interlaminar tawg toughness extension qhov tseem ceeb ntawm cov interfaces sib txawv heev. Qhov tseem ceeb interface txheej lub kaum sab xis dependence yog nthuav. Hauv kev teb rau qhov kev vam khom no, Zhao et al.[5]Raws li lub cev mechanism ntawm lub stratified kuj qhov chaw, nws yog xam tau tias interlaminar tawg toughness stability tus nqi muaj ob feem, ib feem yog cov tawg ua hauj lwm ntawm lub unrelated txheej interface, thiab lwm yam yog lub intralayer puas thiab fiber. Kev ua haujlwm ntawm kev puas tsuaj los ntawm kev sib tsoo. Los ntawm kev txheeb xyuas qhov kawg ntawm qhov kev ntxhov siab hauv pem hauv ntej ntawm cov txheej hauv pem hauv ntej, nws pom tau tias qhov thib ob ntawm kev ua haujlwm tawg yog nyob ntawm qhov tob ntawm qhov delamination pem hauv ntej puas cheeb tsam (raws li qhia hauv daim duab 3), thiab qhov tob ntawm qhov kev puas tsuaj yog proportional rau lub interface layup lub kaum sab xis. Tus qauv theoretical ntawm I-hom tawg toughness stability tus nqi qhia los ntawm sinusoidal muaj nuj nqi ntawm lub interface txheej lub kaum sab xis yog nthuav tawm.

Gong et al.[7]nqa tawm qhov I / II hybrid stratification test nyob rau hauv sib txawv mixing ratios, thiab pom hais tias lub I / II hybrid stratification nyob rau hauv lub laminate kuj muaj ib tug tseem ceeb R tiv thaiv nkhaus yam ntxwv. Los ntawm kev soj ntsuam ntawm cov pob txha toughness ntawm cov ntawv xeem sib txawv, nws pom tau tias tus nqi pib thiab tus nqi ruaj khov ntawm interlaminar pob txha toughness ntawm daim ntawv xeem nce ntxiv nrog qhov nce ntawm qhov sib xyaw. Tsis tas li ntawd, qhov pib thiab ruaj khov tawg toughness ntawm lub interlayer nyob rau hauv sib txawv mixing ratios tau piav qhia los ntawm BK cov qauv.

Nyob rau hauv cov nqe lus ntawm qaug zog stratification, tseem ceeb fiber bridging kuj tau pom thaum lub sij hawm xeem. Los ntawm kev soj ntsuam ntawm cov ntaub ntawv xeem, nws pom tias qhov qaug zog delamination nthuav dav ntawm cov khoom sib xyaw yog cuam tshuam los ntawm "kev tiv thaiv nkhaus", yog li ntawd cov qauv kev qaug zog stratification expansion tus qauv thiab tus nqi pib yuav tsis siv ntxiv lawm. Raws li kev tshawb fawb theoretical, Zhang thiab Peng[4,8,9]qhia txog kev qaug zog delamination expansion tsis kam qhia lub zog xav tau rau kev qaug zog delamination nthuav dav ntawm cov ntaub ntawv sib xyaw, thiab ntxiv tswv yim rau lub zog ua kom muaj zog. Tus nqi tso tawm yog qhov qaug zog stratified expansion tus qauv qauv thiab tus nqi pib ntawm kev tswj tsis tau. Qhov kev siv tau ntawm tus qauv thiab qhov normalized threshold parameter raug txheeb xyuas los ntawm kev sim. Tsis tas li ntawd, Zhao et al.[3]Kev txiav txim siab txog qhov cuam tshuam ntawm fiber ntau bridging, kev ntxhov siab piv thiab qhov sib xyaw ntawm kev sib xyaw ntawm qaug zog stratification thiab nthuav tus cwj pwm, thiab tsim kom muaj ib qho kev qaug zog stratified expansion tus qauv xav txog kev cuam tshuam ntawm kev ntxhov siab. Qhov tseeb ntawm tus qauv tau txheeb xyuas los ntawm kev qaug zog stratification kev ntsuam xyuas nrog qhov sib txawv ntawm kev ntxhov siab thiab kev sib xyaw ua ke. Rau lub cev kom muaj nuj nqis ntawm qaug zog stratified expansion kuj nyob rau hauv lub normalized qaug zog stratified expansion tus qauv, Gong li al.[1]kov yeej qhov tsis muaj zog ntawm txoj kev suav uas tsuas tuaj yeem tau txais cov ntsiab lus tsis txaus ntseeg los ntawm kev sim, thiab tsim kev qaug zog los ntawm lub zog ntawm qhov pom. Ib qho qauv tshuaj ntsuam xyuas rau kev suav ntawm stratified ncua kev tiv thaiv. Tus qauv tuaj yeem paub txog qhov kev txiav txim siab ntau ntawm kev qaug zog stratification thiab nthuav tawm tsis kam, thiab muab kev txhawb nqa theoretical rau daim ntawv thov ntawm cov qauv uas tau hais txog kev qaug zog stratified expansion tus qauv.

Daim duab 1 stratified test device diagram

Daim duab 1 stratified test device diagram

Daim duab 2 Inter-layer fracture toughness R kuj nkhaus[5]

Daim duab 3 Layed ua ntug kev puas tsuaj cheeb tsam thiab stratified ncua morphology[5]

2. Kev kawm lej simulation

Tus lej simulation ntawm cov txheej txheem nthuav dav yog cov ntsiab lus tshawb fawb tseem ceeb hauv kev tsim cov qauv sib xyaw. Thaum kwv yees lub delamination tsis ua hauj lwm ntawm composite unidirectional laminates, cov txheej txheem stratification expansion uas twb muaj lawm feem ntau yog siv tas li interlaminar tawg toughness raws li qhov kev ua tau zoo ntawm cov txheej txheem.[10], los ntawm kev sib piv cov tawg tawm lub zog tso tawm tus nqi thiab interlaminar tawg toughness. Qhov loj los txiav txim seb qhov txheej txheem nthuav dav. Qhov tsis ua hauj lwm mechanism ntawm multi-directional laminates yog complex[11,12], uas yog tus cwj pwm los ntawm qhov tseem ceeb R tsis kam nkhaus[5,13]. Cov txheej txheem txheej txheem nthuav dav uas twb muaj lawm tsis suav cov yam ntxwv no rau hauv tus account thiab tsis siv rau kev simulation ntawm delamination tus cwj pwm ntawm fiber ntau txuas txuas nrog ntau lub laminates. Gong et al.[10, 13]txhim kho cov txheej txheem nthuav dav uas twb muaj lawm thiab tau npaj los qhia txog R qhov nkhaus nkhaus rau hauv cov txheej txheem, thiab raws li qhov no, tau tsim cov txheej txheem nthuav dav uas xav txog qhov cuam tshuam ntawm fiber ntau bridging. Lub ntsiab txhais thiab siv tsis tau ntawm lub bilinear constitutive cohesive unit tau kawm systematically kawm los ntawm cov zauv txoj kev, nrog rau cov thawj interface stiffness, interface zog, viscosity coefficient thiab tsawg kawg nkaus ntawm cov ntsiab lus nyob rau hauv lub cohesive quab yuam cheeb tsam. Tus qauv cohesive unit parameter tau tsim. Thaum kawg, kev ua tau zoo thiab kev siv tau ntawm kev txhim kho txheej txheej nthuav dav thiab cohesive unit parameter qauv raug txheeb xyuas los ntawm qhov kev xeem static stratification. Txawm li cas los xij, cov txheej txheem txhim kho tsuas yog siv tau rau ib-seem txheej txheej simulations vim qhov chaw nyob thiab tsis yog rau ob- lossis peb-dimensional hierarchical extensions. Yuav kom daws tau qhov teeb meem no, tus sau tau hais ntxiv txog qhov tshiab trilinear cohesive force constitutive xav txog fiber ntau bridging.[14]. Txoj kev sib raug zoo haum rau cov txheej txheem txheej txheem ntawm txheej txheej nthuav dav los ntawm kev pom ntawm microscopic, thiab muaj qhov zoo ntawm qhov tsis yooj yim thiab lub ntsiab lus meej.

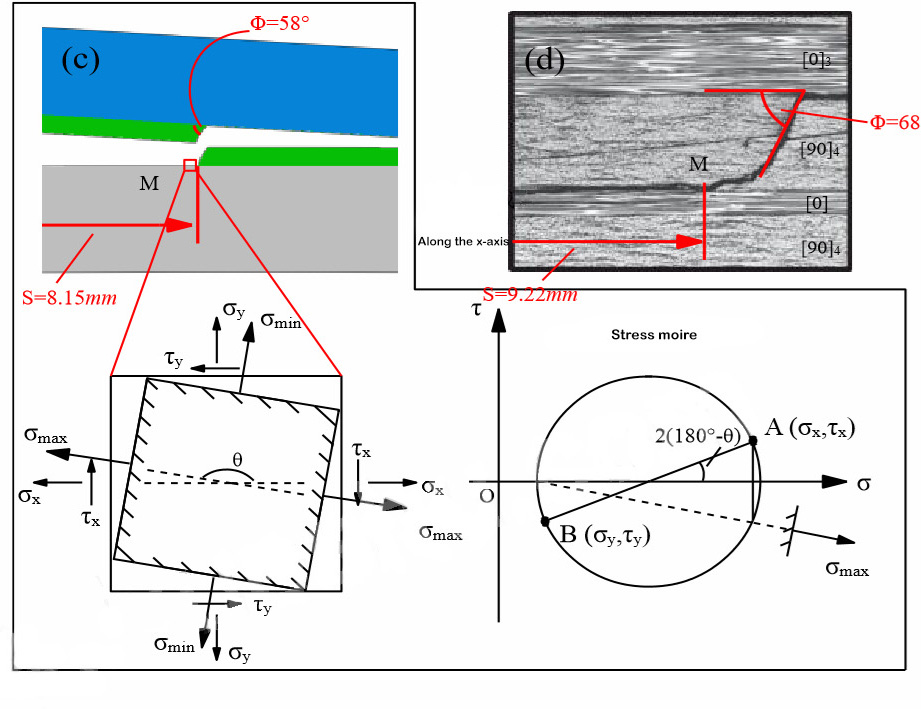

Tsis tas li ntawd, txhawm rau ua kom raug simulate stratified migration phenomenon tshwm sim nyob rau hauv cov txheej txheem stratification ntawm multi-directional laminates[11,12], Zhao et al.[11,12]npaj ib qho kev taw qhia kev sib tsoo qauv raws li txuas ntxiv finite caij, simulating tshwj xeeb tsim. Hierarchical migration nyob rau hauv ib tug composite stratification xeem. Nyob rau tib lub sijhawm, txheej txheej nthuav dav yog npaj rau zigzag txheej nthuav dav tus cwj pwm raws li 90 ° / 90 ° txheej txheej interface, uas yog simulates cov txheej txheem nthuav dav ntawm 90 ° / 90 ° interface.

Daim duab 4 Tus lej simulation ntawm cov txheej txheem tsiv teb tsaws thiab kev sim ua tiav[15]

Daim duab 4 Tus lej simulation ntawm cov txheej txheem tsiv teb tsaws thiab kev sim ua tiav[15]

Xaus

Daim ntawv no tsom mus rau qhov kev tshawb fawb ntawm cov pab pawg no hauv kev sib xyaw laminate delamination. Cov kev sim no feem ntau suav nrog kev cuam tshuam ntawm lub interface layup lub kaum ntse ntse thiab fiber ntau txuas rau ntawm tus cwj pwm zoo li qub thiab qaug zog delamination nthuav dav. Los ntawm ntau qhov kev sim kev tshawb fawb, nws tau pom tias ntau qhov kev coj ua laminate tsis ua haujlwm ntawm cov ntaub ntawv sib xyaw yog qhov nyuaj. Fiber bridging yog ib qho yooj yim toughening mechanism ntawm multi-directional laminates, uas yog lub ntsiab yog vim li cas rau R-kuj nkhaus ntawm interlaminar tawg toughness. Tam sim no, txoj kev tshawb nrhiav R kev tiv thaiv nkhaus nyob rau hauv II stratification yog qhov tsis muaj thiab xav tau kev tshawb fawb ntxiv. Pib los ntawm kev ua haujlwm tsis ua haujlwm, cov qauv kev qaug zog stratification suav nrog ntau yam cuam tshuam los ntawm kev tawm tswv yim, uas yog kev taw qhia ntawm kev tshawb fawb qaug zog stratification. Nyob rau hauv cov nqe lus ntawm cov zauv simulation, pawg neeg tshawb fawb tau npaj ib qho kev txhim kho hierarchical expansion criterion thiab ib tug cohesive constitutive qauv los txiav txim siab lub hwj chim ntawm fiber bridging ntawm lub stratified expansion cwj pwm. Tsis tas li ntawd, qhov txuas ntxiv finite tau siv los ua kom zoo dua simulate qhov tshwm sim hierarchical tsiv teb tsaws. Txoj kev no tshem tawm qhov xav tau ntawm kev faib cell zoo, tshem tawm cov teeb meem cuam tshuam nrog mesh rov faib. Nws muaj qhov tshwj xeeb zoo hauv kev simulating stratification ntawm arbitrary duab, thiab ntau engineering daim ntawv thov kev tshawb fawb ntawm cov qauv no yog xav tau yav tom ntej.[16].

Cov ntaub ntawv

[1] Gong, Y., Zhao, J. Zhang, N. Ib qho qauv tshiab rau kev txiav txim siab qaug zog delamination tsis kam nyob rau hauv kev sib xyaw laminates los ntawm kev pom ntawm lub zog. Compos Sci Technol 2018; 167:489-96.

[2] Zhao, Y.W., Zhang, W. XFEM-raws li qauv rau simulating zigzag delamination kev loj hlob nyob rau hauv laminated composites nyob rau hauv hom I loading. Compos Struct 2017; 160: 1155-62.

[3] Zhao L, Gong, J. Zhang, Y. W. Lu, Peng, N. Kev txhais tshiab ntawm kev qaug zog delamination tus cwj pwm loj hlob hauv CFRP multidirectional laminates. Compos Sci Technol 2016; 133:79–88.

[4] Peng, J., Zhang, L. Zhao, R Bao, H Yang, Fei B. Hom I delamination kev loj hlob ntawm multidirectional composite laminates nyob rau hauv qaug zog loading. J Compos Mater 2011; 45: 1077-90.

[5] Zhao, Y.W., Zhang, Y., Gong, Z., Hu, J. Ib qho piv txwv-raws li qauv ntawm toj siab pob txha toughness nyob rau hauv multidirectional CFRP laminates nyob rau hauv hom kuv loading. Composites Part B: Engineering 2017; 131:196–208.

[6] Zhao L, Gong, J. Zhang, Y. Chen, Fei B. Simulation ntawm delamination kev loj hlob nyob rau hauv multidirectional laminates nyob rau hauv hom I thiab mixed hom I / II loadings siv cohesive ntsiab. Compos Struct 2014; 116: 509-22 .

[7] Zhang Y, Zhang, L., Zhang, J., Hu, C. R-kev coj tus cwj pwm ntawm kev sib xyaw hom I / II delamination hauv carbon / epoxy laminates nrog unidirectional thiab multidirectional interfaces. Compos Struct 2019. (Saib xyuas).

[8] Peng, Xu, J., Zhang, L. Mixed hom delamination kev loj hlob ntawm multidirectional composite laminates nyob rau hauv qaug zog loading. Eng Fract Mech 2012; 96: 676-86.

[9] Zhang J, Peng, L Zhao, Fei B. Fatigue delamination kev loj hlob tus nqi thiab qhov pib ntawm kev sib xyaw laminates nyob rau hauv kev sib xyaw hom kev thauj khoom. Int J Fatigue 2012; 40:7-15.

[10] Gong, Y.W., Zhao, J. Delamination propagation criterion nrog rau cov nyhuv ntawm fiber ntau bridging rau tov-hom I / II delamination nyob rau hauv CFRP multidirectional laminates. Compos Sci Technol 2017; 151: 302-9.

[11] Gong, B. Zhang, SR Hallett. Delamination migration nyob rau hauv multidirectional composite laminates nyob rau hauv hom I quasi-static thiab qaug zog loading. Compos Struct 2018; 189:160–76 .

[12] Y. Gong, B. Zhang, S. Mukhopadhyay, SR Hallett. Kev sim kawm ntawm delamination tsiv teb tsaws nyob rau hauv multidirectional laminates nyob rau hauv hom II zoo li qub thiab qaug zog loading, nrog rau kev sib piv rau hom I. Compos Struct 2018; 201: 683-98.

[13] Gong, Y., Zhao, J. Ib qho kev txhim kho fais fab kev cai lij choj rau kev nthuav tawm delamination nrog cov txiaj ntsig ntawm kev sib txuas ntawm fiber ntau hauv kev sib xyaw ua ke ntawm ntau lub laminates. Compos Struct 2018; 184: 961-8.

[14] Gong, Y.H., Hu, Y.W., Li, W.Y., Zhang, J. Ib qho tshiab peb-linear cohesive cheeb tsam qauv rau kev loj hlob delamination hauv DCB laminates nrog cov nyhuv ntawm fiber ntau bridging. Compos Struct 2019. (Yuav tsum xa)

[15] Zhao J, Zhang, J. XFEM simulation ntawm delamination nyob rau hauv composite laminates. Composites Part A: Applied Science thiab Manufacturing 2016; 80:61-71.

[16] Zhao Libin, Gong Yu, Zhang Jianyu. Kev tshawb fawb nce qib ntawm kev nthuav dav tus cwj pwm ntawm fiber ntau reinforced composite laminates. Phau ntawv Journal of Aeronautical Sciences 2019: 1-28.

Qhov chaw:Gong Yu, Wang Yana, Peng Lei, Zhao Libin, Zhang Jianyu.Study ntawm stratified expansion cwj pwm ntawm advanced carbon fiber reinforced composite laminates [C]. Mechanics thiab Engineering - Kev suav lej thiab kev txheeb xyuas cov ntaub ntawv 2019 Academic Conference. Suav Society of Mechanics, Beijing Mechanics Society, 2019. viav kev

Post lub sij hawm: Nov-15-2019