KANKANI DA INGANCI - Ƙididdigar ƙididdiga da Binciken Bayanai

Makanikai da Injiniya - Lissafin Lambobi da Binciken Bayanai na Taron Ilimi na 2019, Afrilu 19-21, 2019, Beijing

Afrilu 19-21, 2019, Beijing, China

Nazari akan Halayen Faɗawa Mai Layi na Babban Carbon Fiber Ingantattun Haɗin Laminates Sheet

Gong Yu1*, Wang Yana2, Peng Lei3, Zhao Libin4, Zhang Jianyu1

1Jami'ar Chongqing, Chongqing, 400044, Sin

2Cibiyar Nazarin Harkokin Jiragen Sama ta kasar Sin, Cibiyar Bincike Kan Kayayyakin Jiragen Sama ta Beijing, Beijing, 100095, Sin

3Jirgin Kasuwancin China na Cibiyar Nazarin Fasahar Fasahar Jirgin Sama ta Beijing, Beijing, 102211, China

4Jami'ar Beijing na Aeronautics da Astronautics, Beijing, 100191, China

AbstractTsarin laminate yana ɗaya daga cikin abubuwan da aka saba amfani da su don abubuwan haɗin gwiwa, amma delamination ya zama babban yanayin gazawar sa saboda raunin kaddarorin interlaminar. Bincike kan rarrabuwar laminate da yawa da haɓaka haɓaka da aka saba amfani da su a aikin injiniya koyaushe ya kasance babban batu ga malamai. A cikin wannan takarda, an gabatar da sakamakon bincike na fiber carbon fiber ƙarfafa haɗin kai a Jami'ar Chongqing da Jami'ar Beijing ta Aeronautics da Laboratory Fatigue Fracture Laboratory an gabatar da su daga bangarori biyu na bincike na gwaji da ƙididdiga na ƙididdiga. A ƙarshe, ana sa ran alkiblar ci gaban filin.

Mahimman kalmomi:carbon fiber ƙarfafa hadawa, laminate, delamination, gajiya stratification

gabatarwa

Abubuwan da aka haɗa suna da kyawawan kaddarorin kamar ƙayyadaddun ƙayyadaddun ƙarfi da ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙarfi, kuma an yi amfani da su sosai a sararin samaniya, fasahar makamashi, da jigilar jama'a da gini. A lokacin sarrafawa da amfani da kayan haɗin gwiwa, zaruruwa da matrix za su sami digiri daban-daban na lalacewa ƙarƙashin kaya. Hanyoyin gazawar gama gari don haɗaɗɗun laminates sun haɗa da lalacewar tsaka-tsaki da lalacewa a cikin yadudduka. Saboda rashin ƙarfafawa a cikin kauri mai kauri, kayan aikin injiniya na gefe na laminate ba su da kyau, kuma lalacewar lalacewa yana iya faruwa a ƙarƙashin nauyin tasirin waje. Abin da ya faru da faɗaɗa ɓarnar lalacewa zai haifar da raguwar tsattsauran ra'ayi da ƙarfi, har ma yana haifar da haɗari masu haɗari.[1-3]. Sabili da haka, matsalar ƙaddamarwa ta fi damuwa da ƙirar tsari da ƙarfin bincike na kayan da aka haɗa, kuma ya zama dole a yi nazarin yanayin haɓakar haɓakar kayan haɗin gwiwa.[4].

Bincike a kan halayen haɓaka mai laushi na laminate

1. Nazarin gwaji

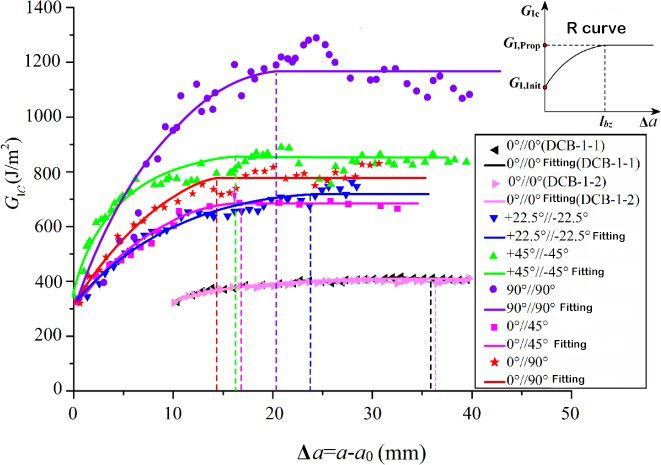

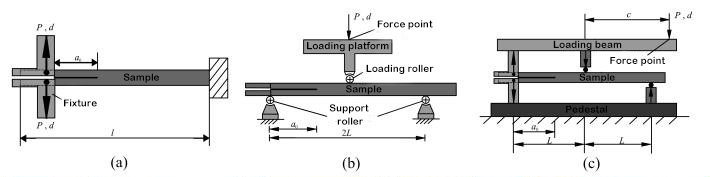

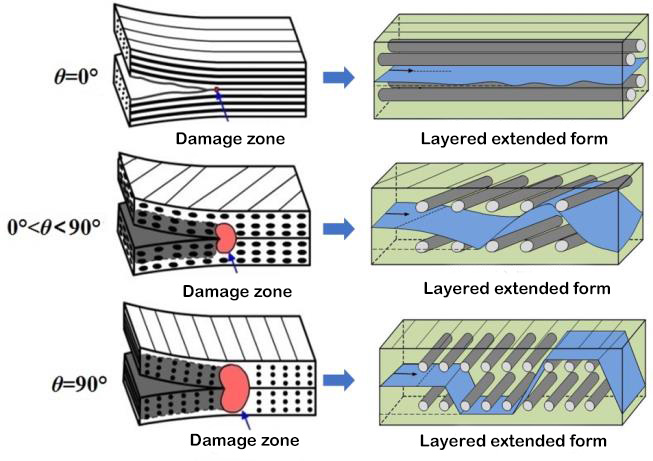

Ƙaƙƙarfan karyewar interlaminar siffa ce ta siffa ta kayan aikin injiniya tsakanin yadudduka masu haɗaka. An kafa ma'auni na gwaji masu dacewa don ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun katsewar Nau'in I, Nau'in II da I/II matasan laminates unidirectional. Ana nuna na'urar gwajin da ta dace a cikin Hoto 1. Duk da haka, ana amfani da laminates masu yawa na kayan haɗin gwiwa a cikin ainihin tsarin injiniya. Sabili da haka, binciken gwaji akan ƙaddamarwa da haɓaka halayyar laminates masu yawa yana da mahimmancin mahimmancin ka'idar da ƙimar injiniya. Ƙaddamarwar Layer Layer Layer da faɗaɗawa yana faruwa tsakanin musaya tare da kusurwoyi na saɓani, kuma yanayin haɓakar shimfidar wuri ya bambanta da na laminates na unidirectional, kuma tsarin faɗaɗa ya fi rikitarwa. Masu bincike suna da ɗan ƙaramin binciken gwaji akan laminates masu yawa, kuma ƙudurin taurin fashewar interlaminar bai riga ya kafa ƙa'idar ƙasa da ƙasa ba. Ƙungiyar binciken ta yi amfani da T700 da T800 carbon fiber don ƙirƙira nau'ikan laminates masu haɗaka tare da kusurwoyin layi na dubawa daban-daban, kuma sun yi nazarin tasirin kusurwar shimfidar wuri da fiber bridging akan a tsaye da halayen delamination na gajiya. An gano cewa gadar fiber da aka kafa ta gefen gefen layin yana da tasiri mai girma akan taurin fashewar interlaminar. Yayin da ƙaddamarwa ta faɗaɗa, taurin raunin interlaminar zai ƙaru a hankali daga ƙananan ƙimar farko, kuma lokacin da stratification ya kai wani tsayin daka, ya kai ƙima mai ƙarfi, wato, yanayin juriya na R. Ƙunƙarar raunin farko na interlayer kusan daidai yake kuma kusan daidai yake da taurin guguwa, wanda ya dogara da taurin karya na matrix kanta.[5, 6]. Koyaya, ƙimar haɓaka ƙarfi ta interlaminar na musaya daban-daban sun bambanta sosai. An gabatar da dogaron kusurwar kusurwar mu'amala mai mahimmanci. Dangane da wannan dogaro, Zhao et al.[5]dangane da tsarin jiki na tushen juriya mai ma'ana, ana la'akari da cewa ƙimar kwanciyar hankali mai ƙarfi ta interlaminar ta ƙunshi sassa biyu, ɓangaren ɗaya shine aikin karaya na ƙirar ƙirar da ba ta da alaƙa, ɗayan kuma shine lalacewar intralayer da fiber. Aiki na karaya da ke haifar da gada. Ta hanyar nazarin ƙayyadaddun ƙayyadaddun ƙayyadaddun abubuwa na filin gaban danniya na gaba mai layi, an gano cewa kashi na biyu na aikin raguwa ya dogara da zurfin yankin lalacewa na gaba (kamar yadda aka nuna a cikin Hoto 3), kuma zurfin yankin lalacewa yana daidai da kusurwar layi na dubawa. An gabatar da ƙirar ƙima na ƙimar ƙarfin ƙarfi taurin nau'in I-type wanda aka bayyana ta aikin sinusoidal na kusurwar Layer na mu'amala.

Gong et al.[7]an gudanar da gwajin I/II matasan a ƙarƙashin ma'auni daban-daban na haɗawa, kuma sun gano cewa I/II matasan stratification a cikin laminate yana da mahimmancin halayen juriya na R. Ta hanyar nazarin taurin karaya tsakanin nau'ikan gwaji daban-daban, an gano cewa ƙimar farko da ƙimar kwanciyar hankali na ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun gwajin ya karu sosai tare da haɓakar haɓakar haɗuwa. Bugu da kari, farkon da kwanciyar hankali taurin karya na interlayer a karkashin ma'auni na BK na iya bayyana shi.

Dangane da ƙaddamarwar gajiya, an kuma lura da gadar fiber mai mahimmanci yayin gwajin. Ta hanyar nazarin bayanan gwajin, an gano cewa haɓakar gajiyar delamination na kayan haɗin gwiwa yana shafar “tsarin juriya”, ta yadda tsarin faɗaɗa ƙimar gajiyar gajiyar gargajiya da ƙimar kofa ba ta da amfani. Bisa nazarin ka'idar, Zhang da Peng[4,8,9]ya gabatar da juriya na faɗaɗa gajiya don bayyana ƙarfin da ake buƙata don faɗaɗa haɓakar gajiyar kayan haɗin gwiwa, kuma ya ƙara ba da shawarar daidaita ƙarfin kuzari. Matsakaicin sakin shine ƙirar ƙimar faɗaɗa madaidaicin gajiya da ƙimar ƙimar ma'aunin sarrafawa. An tabbatar da dacewar samfurin da daidaitaccen ma'aunin ƙofa ta gwaje-gwaje. Har ila yau, Zhao et al.[3]cikakken la'akari da tasirin fiber bridging, danniya rabo da load-mixing rabo a kan gajiya stratification da kuma fadada hali, da kuma kafa wani al'ada gajiya stratified fadada kudi model la'akari da tasirin danniya rabo. An tabbatar da daidaiton samfurin ta gwaje-gwajen kunkuntar gajiya tare da ma'auni daban-daban na danniya da ma'auni. Don adadin jiki na gajiya mai ƙarfi da ƙarfi na haɓaka juriya a cikin ƙirar ƙima mai madaidaicin gajiya mai ƙima, Gong et al.[1]shawo kan raunin hanyar ƙididdiga wanda zai iya samun iyakanceccen madaidaitan bayanai ta hanyar gwaje-gwaje, da kuma kafa gajiya daga mahangar makamashi. Samfurin nazari don lissafin tsayin tsayin juriya. Samfurin zai iya gane ƙididdige ƙayyadaddun ƙayyadaddun ƙayyadaddun gajiyawa da juriya na faɗaɗawa, kuma ya ba da goyan bayan ƙa'idar don aikace-aikacen ƙirar ƙimar faɗuwar gajiya ta al'ada.

Hoto 1 madaidaicin zane na na'urar gwaji

Hoto 1 madaidaicin zane na na'urar gwaji

Hoto 2 Karya taurin tsaka-tsaki R juriya[5]

Hoto na 3 Yankunan lalacewa mai shimfiɗaɗɗen gefen gefe da ƙwanƙwasa ƙaƙƙarfan tsarin halittar jiki[5]

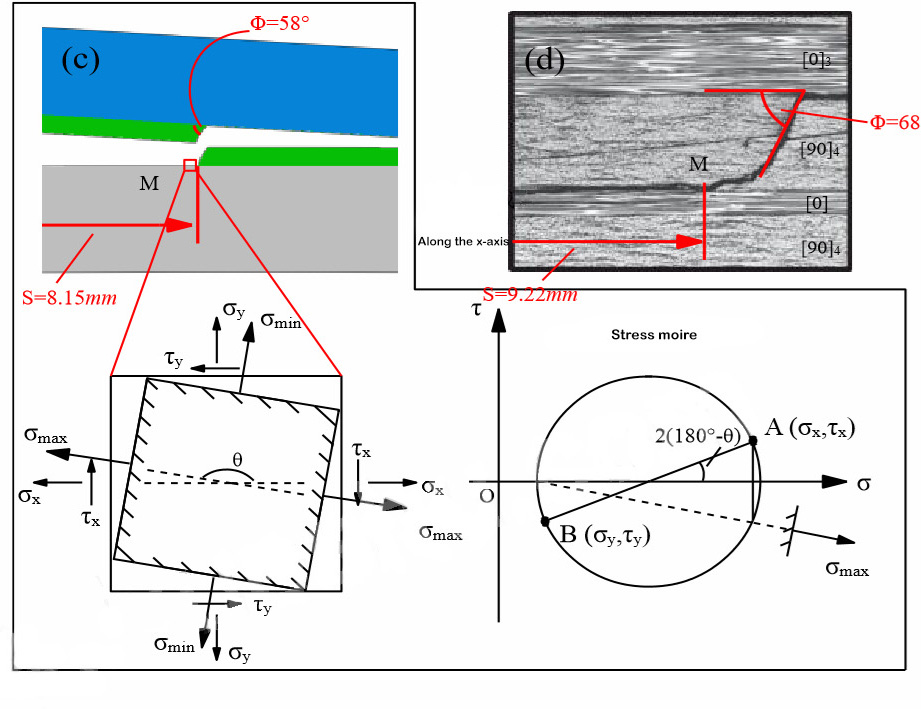

2. Nazarin kwaikwaiyo na lambobi

Kwaikwayon ƙididdiga na faɗaɗa shimfidar wuri muhimmin abun ciki ne na bincike a fagen ƙirar ƙirar tsari. Lokacin tsinkayar gazawar ƙaddamar da laminates ɗin da aka haɗa, ƙa'idodin faɗaɗawa na yau da kullun yawanci suna amfani da tauri na tsaka-tsaki akai-akai azaman ainihin ma'aunin aikin.[10], ta hanyar kwatanta ƙimar sakin makamashi mai fashe da taurin karaya ta interlaminar. Girman don sanin ko shimfidawa yana faɗaɗawa. Hanyar rashin nasara na laminates masu yawa da yawa yana da rikitarwa[11,12], wanda aka kwatanta da mahimmancin juriya na R[5,13]. Sharuɗɗan faɗaɗa shimfidar wuri da ake da su baya ɗaukar wannan fasalin kuma baya amfani da kwaikwaiyon ɗabi'a na ƙayyadaddun laminates mai gada mai ɗauke da fiber. Gong et al.[10, 13]ya inganta ƙa'idodin faɗaɗa madaidaicin da ke akwai kuma ya ba da shawarar gabatar da madaidaicin juriya na R a cikin ma'auni, kuma bisa ga wannan, an kafa ma'aunin faɗaɗa madaidaicin la'akari da tasirin haɗin fiber. An yi nazarin ma'anar da ma'auni na amfani da naúrar haɗin kai na bilinear bisa tsari ta hanyoyin ƙididdigewa, gami da taurin mu'amala ta farko, ƙarfin mu'amala, madaidaicin ɗanƙoƙi da ƙaramin adadin abubuwan da ke cikin yankin ƙarfin haɗin gwiwa. An kafa samfurin siga na ɗaya daidai. A ƙarshe, ana tabbatar da inganci da kuma amfani da ingantaccen ma'aunin faɗaɗa mai faɗi da ƙirar haɗin kai na naúrar ta hanyar gwajin ƙima. Duk da haka, za a iya amfani da ingantattun ma'auni kawai don siminti masu layi ɗaya saboda dogaro da matsayi ba don kari na matsayi biyu ko uku ba. Domin magance wannan matsala, marubucin ya ƙara ba da shawarar sabon ƙarfin haɗin gwiwa na trilinear la'akari da haɗin fiber.[14]. Dangantakar da aka kafa ta dace da hadadden tsari na shimfida shimfidar wuri daga hangen nesa, kuma yana da fa'idodin ma'ana mai sauƙi da bayyanannen ma'anar zahiri.

Bugu da ƙari, don daidaita daidaitaccen yanayin ƙaura na ƙaura gama gari a cikin tsarin rarrabuwa na laminates da yawa.[11,12], Zhao et al.[11,12]ya ba da shawarar ƙirar jagorar hanyar tsaga bisa tsayin daka mai iyaka, yana kwaikwayon ƙira ta musamman. Hierarchical hijirar a cikin wani hadaddiyar giyar gwaji. A lokaci guda, ana ba da shawarar ƙirar faɗaɗa mai shimfiɗa don halayen haɓaka mai shimfiɗaɗɗen zigzag tare da 90°/90° mai shimfiɗaɗɗen keɓancewa, wanda ke daidaita daidaitaccen yanayin faɗaɗawar yanayin 90°/90°.

Hoto 4 Kwaikwayi lambobi na ƙaura mai laushi da sakamakon gwaji[15]

Hoto 4 Kwaikwayi lambobi na ƙaura mai laushi da sakamakon gwaji[15]

Kammalawa

Wannan takarda ta mayar da hankali kan sakamakon bincike na wannan rukuni a cikin filin ƙaddamar da laminate. Fuskokin gwaji sun haɗa da tasirin kusurwar shimfidar mu'amalar mu'amala da igiyar igiyar fiber akan yanayin faɗaɗawa a tsaye da gajiyarwa. Ta hanyar babban adadin gwaje-gwaje na gwaje-gwaje, an gano cewa tsarin gazawar laminate da yawa na kayan haɗin gwiwar yana da rikitarwa. Gadar Fiber shine tsarin daɗaɗɗa gama gari na laminates masu kaifin baki da yawa, wanda shine babban dalilin juriyar juriya ta R na taurin fashewar interlaminar. A halin yanzu, binciken juriya na R a ƙarƙashin tsarin II yana da ƙarancin ƙarancin kuma yana buƙatar ƙarin bincike. An fara daga tsarin gazawar, ƙirar gajiyawar gajiya gami da abubuwan da ke da tasiri daban-daban an gabatar da su, wanda shine jagorar bincike na gajiya. Dangane da simintin ƙididdigewa, ƙungiyar bincike ta ba da shawarar ingantacciyar ma'auni na faɗaɗa matsayi da tsarin haɗin kai don yin la'akari da tasirin haɗin fiber a kan ƙayyadaddun halayen haɓakawa. Bugu da ƙari, ana amfani da ƙaƙƙarfan ƙaƙƙarfan ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun yanayin ƙaura. Wannan hanyar tana kawar da buƙatar rarraba tantanin halitta mai kyau, kawar da matsalolin da ke tattare da sake rarraba raga. Yana da fa'idodi na musamman a cikin simulating da stratification na sabani siffofi, kuma ana buƙatar ƙarin binciken aikin injiniya na wannan hanyar a nan gaba.[16].

Magana

[1] Y Gong, L Zhao, J Zhang, N Hu. Wani sabon samfurin don tantance juriya delamination gajiya a cikin laminates masu haɗaka daga ra'ayi na makamashi. Compos Sci Technol 2018; 167: 489-96.

[2] L Zhao, Y Wang, J Zhang, Y Gong, N Hu, N Li. Samfurin tushen XFEM don kwaikwayi girman zigzag delamination girma a cikin laminated composites karkashin yanayin I loda. Compos Struct 2017; 160: 1155-62.

[3] L Zhao, Y Gong, J Zhang, Y Wang, Z Lu, L Peng, N Hu. Fassarar sabon labari na halayyar haɓakar gajiyar gajiya a cikin laminates multidirectional CFRP. Compos Sci Technol 2016; 133: 79-88.

[4] L Peng, J Zhang, L Zhao, R Bao, H Yang, B Fei. Yanayin I delamination girma na multidirectional composite laminates karkashin gajiya loading. J Compos Mater 2011; 45: 1077-90.

[5] L Zhao, Y Wang, J Zhang, Y Gong, Z Lu, N Hu, J Xu. Samfurin dogaro da musaya na tsangwama mai tsauri a plateau a cikin laminates na CFRP da yawa a ƙarƙashin yanayin I loading. Ƙungiyoyin Ƙungiyoyin B: Injiniya 2017; 131: 196-208.

[6] L Zhao, Y Gong, J Zhang, Y Chen, B Fei. Kwaikwayo na girma delamination a multidirectional laminates karkashin yanayin I da gauraye yanayin I/II loading ta amfani da hade abubuwa. Compos Struct 2014; 116: 509-22.

[7] Y Gong, B Zhang, L Zhao, J Zhang, N Hu, C Zhang. Halin R-curve na gauraye-yanayin I/II delamination a cikin laminates na carbon/epoxy tare da musaya mai madaidaici da muƙamai masu yawa. Compos Struct 2019. (Karƙashin Bita).

[8] L Peng, J Xu, J Zhang, L Zhao. Yanayin gauraye delamination haɓakar laminates mai hadewa da yawa a ƙarƙashin ɗorawa gajiya. Eng Fract Mech 2012; 96: 676-86.

[9] J Zhang, L Peng, L Zhao, B Fei. Matsakaicin haɓakar haɓakar gajiyawa da madaidaitan laminates masu haɗaka ƙarƙashin yanayin yanayin gauraye. Int J Fatigue 2012; 40: 7-15.

[10] Y Gong, L Zhao, J Zhang, Y Wang, N Hu. Ma'auni na haɓakawa ya haɗa da tasirin fiber gada don ƙaddamar da yanayin I/II gauraye a cikin laminates multidirectional CFRP. Compos Sci Technol 2017; 151: 302-9.

[11] Y Gong, B Zhang, SR Hallett. Hijira Delamination a cikin multidirectional composite laminates karkashin yanayin I m da gajiya loading. Compos Struct 2018; 189: 160-76.

[12] Y Gong, B Zhang, S Mukhopadhyay, SR Hallett. Nazarin gwaji akan ƙaura delamination a cikin laminates multidirectional a ƙarƙashin yanayin II a tsaye da nauyin gajiya, tare da kwatanta yanayin I. Compos Struct 2018; 201: 683-98.

[13] Y Gong, L Zhao, J Zhang, N Hu. Ingantacciyar ma'aunin dokar iko don yaɗuwar lalata tare da tasirin babban shingen fiber a cikin laminates masu yawa. Compos Struct 2018; 184: 961-8.

[14] Y Gong, Y Hou, L Zhao, W Li, G Yang, J Zhang, N Hu. Wani sabon salo na yanki na haɗin kai mai layi uku don haɓakar haɓakawa a cikin DCB laminates tare da tasirin haɗin fiber. Compos Struct 2019. (Za a ƙaddamar)

[15] L Zhao, J Zhi, J Zhang, Z Liu, N Hu. XFEM kwaikwayo na delamination a cikin laminates masu haɗaka. Rukunin Rubuce-rubucen Sashe na A: Ƙwararren Kimiyya da Kera 2016; 80: 61-71.

[16] Zhao Libin, Gong Yu, Zhang Jianyu. Ci gaban bincike a kan ƙayyadaddun halayen faɗaɗawa na ƙarfafa abubuwan haɗin fiber. Jaridar Kimiyyar Aeronautical 2019: 1-28.

Source:Gong Yu, Wang Yana, Peng Lei, Zhao Libin. Makanikai da Injiniya - Lissafin Lambobi da Binciken Bayanai na Taron Ilimi na 2019. Ƙungiyar Makanikai ta kasar Sin, Ƙungiyar Makanikai ta Beijing, 2019. ta ixueshu

Lokacin aikawa: Nuwamba 15-2019