MECHINA LE BOENJENYERE - Numerical Computation and Data Analysis

Mechanics le Boenjiniere - Seboka sa Lithuto sa Lipalo le Tlhahlobo ea Lintlha tsa 2019, April 19-21, 2019, Beijing

La 19-21 Mmesa, 2019, Beijing, China

Ho Ithuta ka Boitšoaro ba Katoloso ea Letlapa la Letlapa la Letlapa la Khabone le Matlafalitsoeng

Gong Yu1*, Wang Yana2, Peng Lei3, Zhao Libin4, Zhang Jianyu1

1Univesithi ea Chongqing, Chongqing, 400044, China

2Setsi sa Patlisiso ea Lifofane tsa China Beijing Setsi sa Patlisiso ea Lisebelisoa tsa Aeronautical, Beijing, 100095, China

3China Commercial Aircraft Beijing Civil Aircraft Technology Research Center, Beijing, 102211, Chaena

4Univesithi ea Beijing ea Aeronautics le Astronautics, Beijing, 100191, Chaena

KakaretsoSebopeho sa laminate ke e 'ngoe ea litlhophiso tse ngata tse sebelisoang ka ho fetisisa bakeng sa lihlopha, empa delamination e fetoha mokhoa oa eona o ka sehloohong oa ho hlōleha ka lebaka la thepa e fokolang ea interlaminar. Lipatlisiso mabapi le stratification ea lilae tse ngata tsa laminate le boits'oaro ba katoloso bo sebelisoang hangata ts'ebetsong ea boenjineri esale e le taba e chesang haholo ho litsebi. Ka pampiri ena, liphetho tsa lipatlisiso tsa carbon fiber reinforced composite delamination Univesithing ea Chongqing le Beijing University of Aeronautics and Astronautics Fatigue Fracture Laboratory li hlahisoa ho tsoa likarolong tse peli tsa lipatlisiso tsa liteko le papiso ea lipalo. Qetellong, tataiso ea nts'etsopele ea tšimo e lebelletsoe.

Mantsoe a sehlooho:carbon faeba matlafatsoa motsoako, laminate, delamination, mokhathala stratification

selelekela

Lisebelisoa tse kopantsoeng li na le thepa e ntle haholo joalo ka matla a khethehileng a phahameng le ho satalla ho khethehileng, 'me li sebelisitsoe haholo sebakeng sa sefofane, theknoloji ea matla, le lipalangoang tsa sechaba le kaho. Nakong ea ts'ebetso le ts'ebeliso ea lisebelisoa tse kopantsoeng, likhoele le matrix li tla ba le tšenyo e fapaneng tlas'a mojaro. Mekhoa e tloaelehileng ea ho hlōleha bakeng sa li-laminate tse kopantsoeng li kenyelletsa tšenyo ea li-interlayer le tšenyo ka har'a lihlopha. Ka lebaka la khaello ea matlafatso ka tataiso ea botenya, thepa ea morao-rao ea laminate e fokola, 'me tšenyo ea delamination e ka etsahala haholo tlas'a meroalo ea tšusumetso e ka ntle. Ho ba teng le ho atoloha ha tšenyo ea stratified ho tla lebisa ho fokotseng ho tiea le matla a sebopeho, esita le ho baka likotsi tse mpe.[1-3]. Ka hona, bothata ba delamination bo ameha le ho feta ke moralo oa sebopeho le tlhahlobo ea matla ea lisebelisoa tse kopaneng, 'me hoa hlokahala ho ithuta ka boits'oaro bo atolositsoeng ba lisebelisoa tse kopaneng.[4].

Patlisiso mabapi le boits'oaro bo atolositsoeng ba laminate

1. Boithuto ba liteko

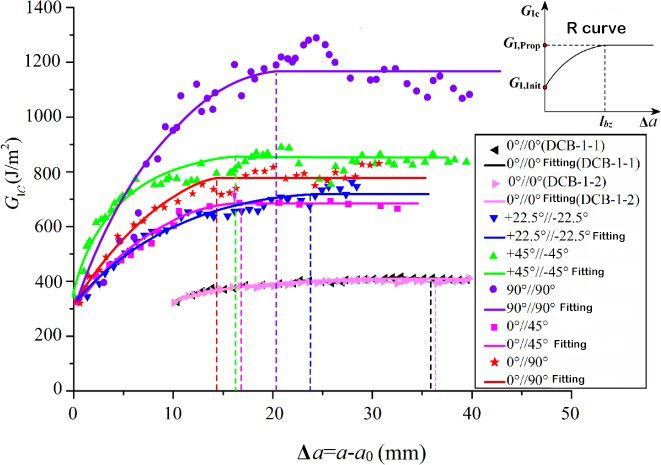

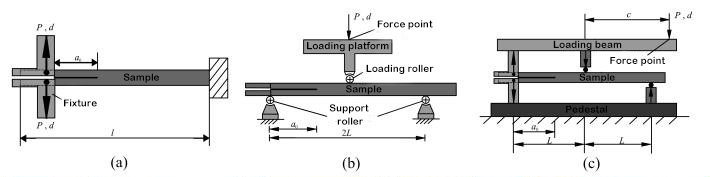

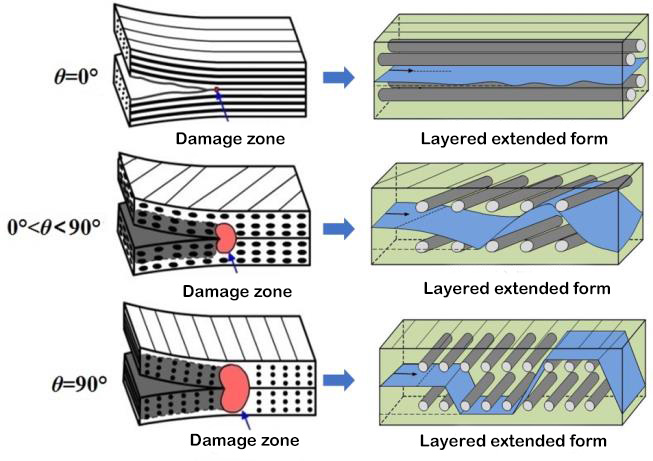

Interlaminar fracture toughness ke tšobotsi e khethollang thepa ea mochine pakeng tsa lihlopha tse kopantsoeng. Litekanyetso tse tsamaellanang tsa liteko li thehiloe bakeng sa qeto ea ho tiea ha fracture ea interlaminar ea Mofuta oa I, Mofuta oa II le I/II hybrid unidirectional laminates. Lisebelisoa tse lumellanang tsa liteko li bontšoa ho Setšoantšo sa 1. Leha ho le joalo, li-laminates tse nang le mekhoa e mengata ea lisebelisoa tse kopantsoeng li atisa ho sebelisoa mohahong oa sebele oa boenjiniere. Ka hona, boithuto ba liteko mabapi le boits'oaro ba stratification le katoloso ea li-laminate tse nang le mahlakore a mangata li na le bohlokoa ba theory le boleng ba boenjiniere. Ho qala le ho atolosoa ha li-multi-layer laminate ho etsahala pakeng tsa li-interfaces tse nang le li-angles tse sa lumellaneng, 'me boitšoaro ba ho atolosa bo fapaneng bo fapane haholo le ba unidirectional laminate,' me mochine oa ho atolosa o rarahane le ho feta. Bafuputsi ba na le liphuputso tse fokolang tse batlang li le teng ka li-laminate tse nang le mahlakore a mangata, 'me boikemisetso ba ho robeha ha interlaminar ha bo so thehe maemo a machaba. Sehlopha sa lipatlisiso se sebelisitse T700 le T800 carbon fiber ho rala mefuta e fapaneng ea laminate e nang le li-angles tse fapaneng tsa sebopeho sa sebopeho, 'me e ithutile tšusumetso ea sebopeho sa interface layup angle le fiber bridging boitšoarong bo tsitsitseng le bo khathetseng ba delamination. Ho 'nile ha fumanoa hore faeba borokho bo entsoeng ke trailing bohale ba lera na le tšusumetso e khōlō ka interlaminar fracture toughness. Ha stratification e ntse e atoloha, ho thatafala ha interlaminar fracture ho tla eketseha butle-butle ho tloha boleng bo tlaase ba pele, 'me ha stratification e fihla bolelele bo itseng, e fihla boleng bo tsitsitseng, ke hore, ts'ebetso ea R ho hanyetsa mokokotlo. Matla a pele a ho robeha ha interlayer a batla a lekana 'me a batla a lekana le boima ba fracture ea resin, e itšetlehileng ka ho robeha ho thata ha matrix ka boeona.[5, 6]. Leha ho le joalo, boleng ba katoloso ea boits'oaro ba interlaminar fracture ea li-interfaces tse fapaneng bo fapana haholo. Ho hlahisoa ho ipapisitsoe le ho its'etleha ka sekhahla sa sehokelo. Ha a arabela ho itšetlehile ka sena, Zhao et al.[5]e thehiloeng mochine oa 'mele oa stratified ho hanyetsa mohloli, ho nkoa hore interlaminar fracture toughness boleng ba botsitso e na le likarolo tse peli, karolo e' ngoe ke fracture mosebetsi oa segokanyimmediamentsi sa sebolokigolo sa amaneng, 'me karolo e' ngoe ke tšenyo e intralayer le faeba. Mosebetsi wa ho qhetsola o bakoang ke borokgo. Ka tlhahlobo ea finite element ea tšimo ea khatello ea pele ea karolo e ka pele ea lera, ho fumanoa hore karolo ea bobeli ea mosebetsi oa fracture e itšetlehile ka botebo ba sebaka sa tšenyo ea pele ea delamination (joalokaha ho bontšitsoe setšoantšong sa 3), 'me botebo ba sebaka sa tšenyo se lekana le sehokelo sa layup angle. Mohlala oa khopolo-taba oa boleng ba botsitso ba botsitso ba mofuta oa I-fracture o hlahisoang ke ts'ebetso ea sinusoidal ea angle layer ea interface e hlahisoa.

Gong et al.[7]e ile ea etsa tlhahlobo ea stratification ea I/II ka tlas'a likarolo tse fapaneng tsa ho kopanya, 'me ea fumana hore I/II hybrid stratification ka laminate e boetse e na le litšobotsi tsa bohlokoa tsa R ho hanyetsa curve. Ka tlhahlobo ea ho thatafala ha fracture pakeng tsa likotoana tse fapaneng tsa teko, ho fumanoa hore boleng ba pele le boleng bo tsitsitseng ba interlaminar fracture toughness ea sengoathoana sa teko bo eketseha haholo ka ho eketseha ha karo-karolelano ea ho kopanya. Ho phaella moo, ho thatafala ha fracture ea pele le e tsitsitseng ea interlayer tlas'a likarolo tse fapaneng tsa ho kopanya ho ka hlalosoa ke mokhoa oa BK.

Mabapi le stratification ea mokhathala, borokho ba bohlokoa ba fiber le bona bo ile ba bonoa nakong ea tlhahlobo. Ka tlhahlobo ea tlhaiso-leseling ea tlhahlobo, ho fumanoe hore keketseho ea mokhathala oa delamination ea thepa e kopaneng e angoa ke "mokokotlo oa ho hanyetsa", e le hore mohlala oa sekhahla sa katoloso ea mokhathala o tloaelehileng le boleng ba monyako ha li sa sebetsa. Motheong oa tlhahlobo ea theory, Zhang le Peng[4,8,9]e hlahisitse khanyetso ea katoloso ea mokhathala ho hlahisa matla a hlokahalang bakeng sa katoloso ea mokhathala oa delamination ea lisebelisoa tse kopaneng, mme a fana ka tlhahiso ea matla a tloaelehileng a khatello. Sekhahla sa tokollo ke mohlala oa sekhahla sa katoloso ea mokhathala o hlophisitsoeng le boleng ba li-parameter tsa taolo. Ho sebetsa ha mohlala le parameter e tloaelehileng ea moeli ho netefatsoa ke liteko. Ho feta moo, Zhao et al.[3]e nahannoe ka botlalo ka litlamorao tsa bridging ea fiber, karo-karolelano ea khatello ea maikutlo le karo-karolelano ea moroalo holim'a stratification ea mokhathala le boitšoaro ba katoloso, 'me e thehile mokhoa o tloaelehileng oa mokhathala o hlophisitsoeng oa sekhahla sa katoloso ho nahanoa ka tšusumetso ea karolelano ea khatello ea maikutlo. Ho nepahala ha mohlala ho netefalitsoe ke liteko tsa stratification tsa mokhathala tse nang le likhakanyo tse fapaneng tsa khatello ea maikutlo le ho kopanya ho kopanya. Bakeng sa palo ea 'mele ea mokhathala o matlafalitsoeng ke katoloso ea ho hanyetsa mokhathala o tloaelehileng oa stratified sekhahla sa katoloso, Gong et al.[1]hlola bofokoli ba mokhoa oa ho bala o ka fumanang lintlha tse fokolang feela tsa data ka liteko, le ho theha mokhathala ho tsoa ponong ea matla. Mohlala oa tlhahlobo bakeng sa palo ea khanyetso e atolositsoeng ea stratified. Mohlala o ka hlokomela boikemisetso ba bongata ba stratification ea mokhathala le ho hanyetsa katoloso, le ho fana ka tšehetso ea khopolo-taba bakeng sa ts'ebeliso ea mokhoa o reriloeng o tloaelehileng oa mokhathala stratified sekhahla sa katoloso.

Setšoantšo sa 1 stratified test sesebediswa diagram

Setšoantšo sa 1 stratified test sesebediswa diagram

Setšoantšo sa 2 Inter-layer fracture toughness R resistance curve[5]

Setšoantšo sa 3 Sebaka sa tšenyo se senyehileng se ka sehloohong le sebopeho se atolositsoeng sa stratified[5]

2. Thuto ea papiso ea lipalo

Papiso ea lipalo ea katoloso ea lera ke lintlha tsa bohlokoa tsa lipatlisiso lefapheng la moralo o kopaneng oa sebopeho. Ha u bolela esale pele ho hloleha ha delamination ea li-laminate tsa composite unidirectional, mekhoa e teng ea katoloso ea stratification hangata e sebelisa ho tiea ha fracture ea interlaminar joalo ka paramethara ea ts'ebetso ea mantlha.[10], ka ho bapisa sekhahla sa ho lokolloa ha matla a crack tip le boima ba ho robeha ha interlaminar. Boholo ba ho bona hore na layering e ntse e hola. Mokhoa oa ho hlōleha ha li-laminates tse ngata-ngata o rarahane[11,12], e khetholloang ka li-curve tsa bohlokoa tsa R resistance[5,13]. Mekhoa e teng ea katoloso ea lera ha e nke tšobotsi ena hloko ebile ha e sebetse ho papisong ea boits'oaro ba delamination ea li-fiber-containing bridged multidirectional laminates. Gong et al.[10, 13]e ntlafalitse mekhoa e teng ea katoloso ea stratified 'me e sisinya ho hlahisa lekhalo la ho hanyetsa R ho litekanyetso,' me ho itšetlehile ka sena, ho thehile mokhoa oa ho atolosa stratified ho nahanoa ka liphello tsa fiber bridging. Tlhaloso le ts'ebeliso ea litekanyetso tsa "bilinear constitutive cohesive unit" li ile tsa ithutoa ka mokhoa o hlophisitsoeng ka mekhoa ea lipalo, ho kenyelletsa le ho satalla ha sebopeho sa pele, matla a sehokelo, coefficient ea viscosity le palo e fokolang ea likarolo sebakeng sa matla a kopaneng. Ho ile ha thehoa mohlala oa parameter ea cohesive unit e lumellanang. Qetellong, ts'ebetso le ts'ebetso ea mokhoa o ntlafalitsoeng oa katoloso ea lera le mohlala o kopaneng oa paramethara li netefatsoa ke tlhahlobo ea stratification ea static. Leha ho le joalo, mekhoa e ntlafetseng e ka sebelisoa feela bakeng sa lipapiso tse nang le lehlakore le le leng ka lebaka la ho itšetleha ka maemo eseng bakeng sa katoloso ea maemo a mabeli kapa a mararo. E le ho rarolla bothata bona, mongoli o ile a boela a etsa tlhahiso ea hore ho be le matla a macha a kopantsoeng a trilinear a nahanang ka ho kopanya fiber.[14]. Kamano ea motheo e lumellana le ts'ebetso e rarahaneng ea katoloso ea lera ho tloha ponong ea microscopic, 'me e na le melemo ea liparamente tse bonolo le moelelo o hlakileng oa' mele.

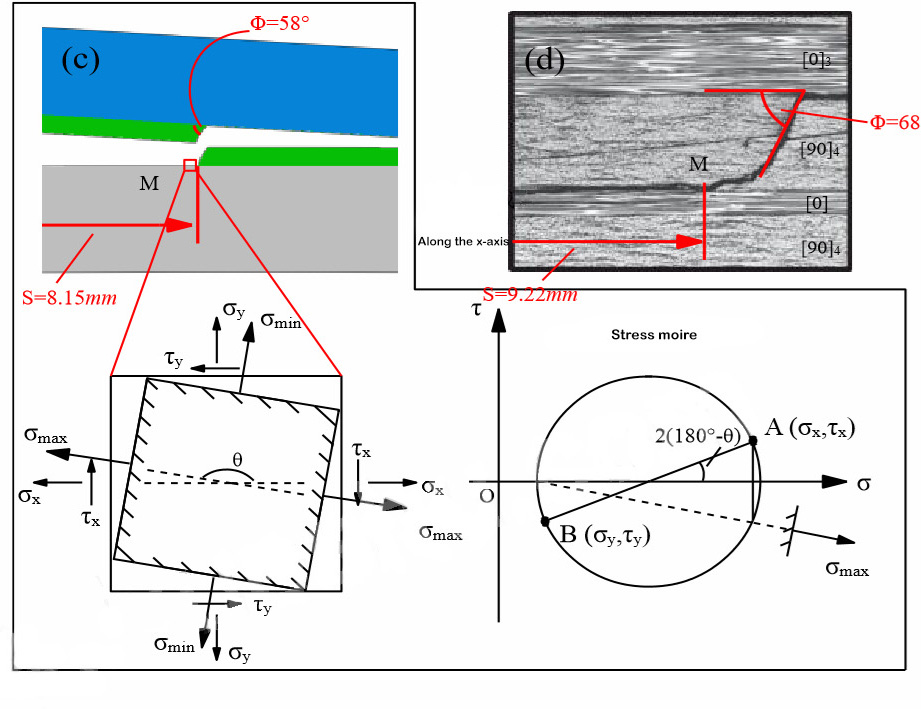

Ho phaella moo, e le hore ho ka nepo ho etsisa stratified falla ketsahalo e tloaelehileng ka stratification tshebetso ya laminate tse ngata-directional.[11,12], Zhao et al.[11,12]e hlahisitse mohlala oa tataiso ea "crack path" e thehiloeng holim'a karolo e atolositsoeng ea moeli, e etsisang moralo o khethehileng. Ho falla ha maemo a phahameng tekong ea stratification e kopaneng. Ka nako e ts'oanang, ho etsoa tlhahiso ea mofuta oa katoloso ea lera bakeng sa boits'oaro bo atolositsoeng ba zigzag hammoho le 90 °/90 ° segokanyimmediamentsi sa sebolokigolo, se etsisang boits'oaro ba katoloso ea 90°/90°.

Setšoantšo sa 4 Papiso ea lipalo ea ho falla ha layered le liphetho tsa liteko[15]

Setšoantšo sa 4 Papiso ea lipalo ea ho falla ha layered le liphetho tsa liteko[15]

Qetello

Pampiri ena e shebana le liphetho tsa lipatlisiso tsa sehlopha sena lefapheng la composite laminate delamination. Likarolo tsa liteko haholo-holo li kenyelletsa tšusumetso ea sehokelo sa sebopeho sa sebopeho le borokho ba faeba boits'oarong ba katoloso ea static le mokhathala. Ka palo e kholo ea liphuputso tsa liteko, ho fumanoa hore mokhoa oa ho hloleha ha laminate oa mefuta e mengata oa lisebelisoa tse kopantsoeng o rarahane. Fiber bridging ke mokhoa o tloaelehileng oa ho toughening oa li-laminate tse nang le litsela tse ngata, e leng lebaka le ka sehloohong la ho hanyetsa R-restance curve ea interlaminar fracture toughness. Hajoale, thuto ea R resistance curve tlasa II stratification e batla e haella mme e hloka lipatlisiso tse ling. Ho qala ka mokhoa oa ho hloleha, ho hlahisoa mofuta oa mokhathala oa stratification ho kenyelletsa le lintlha tse fapaneng tse susumetsang, e leng tataiso ea lipatlisiso tsa stratification ea mokhathala. Mabapi le papiso ea lipalo, sehlopha sa lipatlisiso se khothalelitse mokhoa o ntlafalitsoeng oa katoloso ea maemo le mohlala o kopaneng oa ho nahana ka tšusumetso ea borokho ba fiber boits'oarong ba katoloso ea stratified. Ho feta moo, karolo e atolositsoeng ea finite e sebelisoa ho etsisa hantle boemo ba ho falla ha maemo. Mokhoa ona o felisa tlhokahalo ea karohano e ntle ea lisele, ho felisa mathata a amanang le karohano ea marang-rang. E na le melemo e ikhethang ea ho etsisa stratification ea libopeho tse sa lumellaneng, 'me lipatlisiso tse eketsehileng tsa kopo ea boenjiniere tsa mokhoa ona lia hlokahala nakong e tlang.[16].

Litšupiso

[1] Y Gong, L Zhao, J Zhang, N Hu. Mohlala o mocha oa ho khetholla mokhathala oa delamination khanyetso ho li-laminate tse kopaneng ho latela pono ea matla. Compos Sci Technol 2018; 167: 489-96.

[2] L Zhao, Y Wang, J Zhang, Y Gong, N Hu, N Li. XFEM e thehiloeng ho mohlala bakeng sa ho etsisa kholo ea zigzag delamination ka li-composite tsa laminated tlas'a mokhoa oo ke o kenyang. Compos Struct 2017; 160: 1155-62.

[3] L Zhao, Y Gong, J Zhang, Y Wang, Z Lu, L Peng, N Hu. Tlhaloso e ncha ea boits'oaro ba kholo ea delamination ho CFRP multidirectional laminates. Compos Sci Technol 2016; 133:79-88 .

[4] L Peng, J Zhang, L Zhao, R Bao, H Yang, B Fei. Mode I delamination kgolo ya multidirectional composite laminates tlas'a mokhathala loading. J Compos Mater 2011; 45: 1077-90.

[5] L Zhao, Y Wang, J Zhang, Y Gong, Z Lu, N Hu, J Xu. Mohlala o itšetlehileng ka segokanyimmediamentsi sa sebolokigolo sa fracture toughness in multidirectional CFRP laminates tlas'a mode I loading. Likarolo Karolo ea B: Boenjiniere 2017; 131: 196-208 .

[6] L Zhao, Y Gong, J Zhang, Y Chen, B Fei. Ketsiso ea kholo ea delamination ka laminates multidirectional tlas'a mode I le e tsoakiloeng mode I/II loadings sebelisa lintho tse momahaneng. Compos Struct 2014; 116: 509-22 .

[7] Y Gong, B Zhang, L Zhao, J Zhang, N Hu, C Zhang. Boitšoaro ba R-curve ea mokhoa o tsoakiloeng oa I/II delamination ka carbon/epoxy laminates e nang le li-interface tsa unidirectional le multidirectional. Compos Struct 2019. (Tlas'a Tlhahlobo).

[8] L Peng, J Xu, J Zhang, L Zhao. Mokhoa o tsoakiloeng oa delamination kgolo ea multidirectional composite laminates tlas'a mokhathala loading. Eng Fract Mech 2012; 96: 676-86.

[9] J Zhang, L Peng, L Zhao, B Fei. Mokhathala delamination kgolo ditefello le menyako ea composite laminates tlas'a tsoakiloeng mode loading. Int J Fatigue 2012; 40:7-15 .

[10] Y Gong, L Zhao, J Zhang, Y Wang, N Hu. Tekanyetso ea phatlalatso ea Delamination ho kenyelletsa le phello ea borokho ba fiber bakeng sa delamination ea mofuta oa I/II ho CFRP multidirectional laminates. Compos Sci Technol 2017; 151: 302-9 .

[11] Y Gong, B Zhang, SR Hallett. Delamination falla ka multidirectional composite laminates tlas'a mode I quasi-static le mokhathala loading. Compos Struct 2018; 189: 160-76.

[12] Y Gong, B Zhang, S Mukhopadhyay, SR Hallett. Boithuto ba liteko mabapi le ho falla ha delamination ka li-laminates tsa multidirectional tlas'a mokhoa oa II o tsitsitseng le oa mokhathala, ha o bapisoa le mokhoa oa I. Compos Struct 2018; 201: 683-98.

[13] Y Gong, L Zhao, J Zhang, N Hu. Mokhoa o ntlafalitsoeng oa molao oa matla bakeng sa phatlalatso ea delamination ka phello ea borokho bo boholo ba fiber ka har'a li-laminate tse kopaneng tse fapaneng. Compos Struct 2018; 184: 961-8.

[14] Y Gong, Y Hou, L Zhao, W Li, G Yang, J Zhang, N Hu. Mofuta o mocha oa mela e meraro e hokahaneng bakeng sa kholo ea delamination ho DCB laminates ka phello ea borokho ba fiber. Compos Struct 2019. (E tla romelloa)

[15] L Zhao, J Zhi, J Zhang, Z Liu, N Hu. XFEM papiso ea delamination ka li-laminate tse kopaneng. Likopano Karolo ea A: Saense e Sebelisoang le Tlhahiso ea 2016; 80: 61-71 .

[16] Zhao Libin, Gong Yu, Zhang Jianyu. Tsoelo-pele ea lipatlisiso mabapi le boitšoaro ba katoloso ea stratified ea li-fiber reinforced composite laminates. Journal of Aeronautical Sciences 2019: 1-28.

Mohloli:Gong Yu, Wang Yana, Peng Lei, Zhao Libin, Zhang Jianyu.Thuto e mabapi le stratified katoloso ea boitšoaro ba e tsoetseng pele carbon faeba reinforced composite laminates[C]. Mechanics le Boenjiniere - Seboka sa Thuto sa 2019 sa Numerical Computation le Data Analysis. Mokhatlo oa China oa Mechanics, Beijing Mechanics Society, 2019. ka ixueshu

Nako ea poso: Nov-15-2019