MACHANICS UYE ENGINEERING - Numerical Computation uye Data Analysis

Mechanics uye Injiniya - Nhamba Yekuverengera uye Data Analysis 2019 Academic Musangano, Kubvumbi 19-21, 2019, Beijing

Kubvumbi 19-21, 2019, Beijing, China

Kudzidza paLayered Kuwedzera Maitiro eAdvanced Carbon Fiber Yakasimbiswa Inoumbwa Yakaumbwa Laminates Sheet.

Gong Yu1*, Wang Yana2, Peng Lei3, Zhao Libin4, Zhang Jianyu1

1Chongqing University, Chongqing, 400044, China

2China Aviation Research Institute Beijing Aeronautical Materials Research Institute, Beijing, 100095, China

3China Commercial Aircraft Beijing Civil Aircraft Technology Research Center, Beijing, 102211, China

4Beijing University yeAeronautics uye Astronautics, Beijing, 100191, China

AbstractLaminate chimiro ndechimwe cheanonyanya kushandiswa maumbirwo emakombisi emakombisi, asi delamination inova yayo huru yekutadza maitiro nekuda kwehutera hweinterlaminar zvivakwa. Tsvagiridzo pamusoro peiyo yakawanda-layer laminate stratification uye hunhu hwekuwedzera hunowanzo shandiswa mukuita engineering yagara iri nyaya inopisa kuvadzidzi. Mubepa rino, mhedzisiro yekutsvagisa kabhoni fiber yakasimbisa composite delamination muChongqing University uye Beijing University yeAeronautics uye Astronautics Kuneta Fracture Laboratory inounzwa kubva kune maviri maficha ekutsvagisa kuyedza uye kuenzanisa nhamba. Pakupedzisira, nzira yekusimudzira yemunda inotarisirwa.

Keywords:kabhoni fiber yakasimbiswa inoumbwa, laminate, delamination, kuneta stratification

sumo

Zvigadzirwa zveComposite zvine zvivakwa zvakanakisa senge yakakwira chaiyo kusimba uye yakanyanya kuomarara, uye yakashandiswa zvakanyanya mumhepo, magetsi tekinoroji, uye zvekufambisa nekuvaka. Munguva yekugadziriswa uye kushandiswa kwezvinhu zvakasanganiswa, mafiber uye matrix anozopinda madhigirii akasiyana ekukuvadza pasi pemutoro. Kazhinji kukundikana modes kune composite laminates zvinosanganisira interlayer kukuvara uye kukuvara mukati akaturikidzana. Nekuda kwekushaikwa kwekusimbisa mune ukobvu kutungamira, iyo lateral mechanical zvimiro zvelaminate hazvina kunaka, uye delamination kukuvara kunowanzoitika pasi pemitoro yekunze. Kuitika uye kuwedzera kwekukuvadzwa kwakaomeswa kunotungamira mukudzikira kwekusimba kwechimiro uye simba, uye kunyange kukonzera tsaona dzinotyisa.[1-3]. Naizvozvo, dambudziko re delamination rinowedzera uye rinonyanya kunetseka nedhizaini yedhizaini uye kuongororwa kwesimba kwezvinhu zvinoumbwa, uye zvinodikanwa kuti udzidze yakaturikidzana yekuwedzera maitiro ezvakaumbwa zvinhu.[4].

Tsvagiridzo pane akaturikidzana ekuwedzera maitiro e laminate

1. Chidzidzo chekuedza

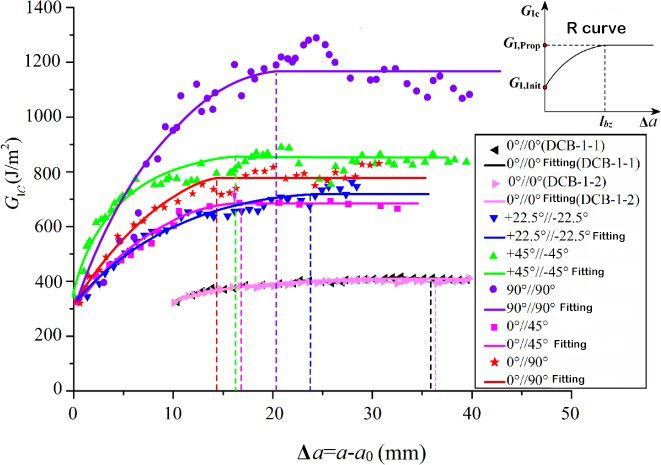

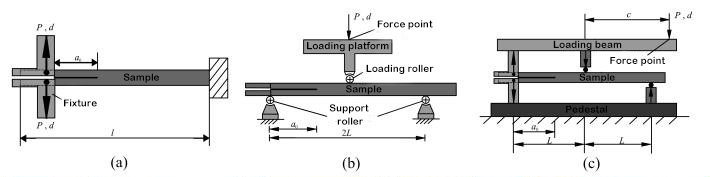

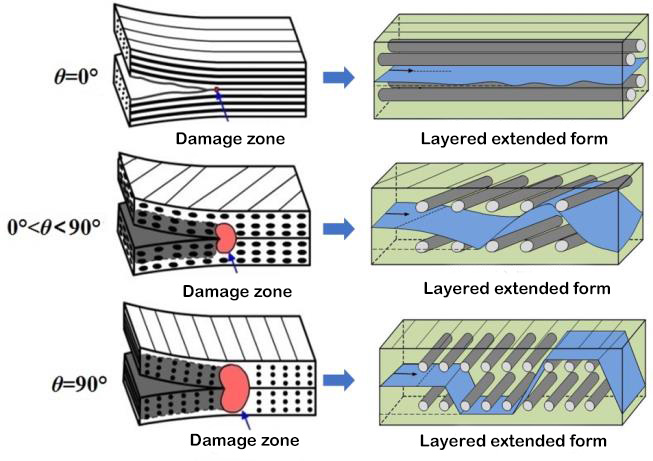

Interlaminar fracture toughness ndiyo hunhu parameter yemakanika zvivakwa pakati pezvikamu zvakaumbwa. Zvinoenderana bvunzo zviyero zvakatemerwa kuomesesa kweiyo interlaminar fracture kuomarara kweType I, Type II uye I/II hybrid unidirectional laminates. Iyo inoenderana bvunzo zvishandiso inoratidzwa muMufananidzo 1. Zvisinei, iyo yakawanda-directional laminates yezvakasanganiswa zvinhu inowanzoshandiswa mune chaiyo engineering chimiro. Nokudaro, chidzidzo chekuedza pamusoro pekugadzirisa uye kuwedzera maitiro e-multi-directional laminates inonyanya kukosha kukosha kwezvinyorwa uye kukosha kweinjiniya. Multi-layer laminate layer initiation uye kuwedzera kunoitika pakati pemainterface nemakona ekumisa maenji, uye maitiro ekuwedzera akaturikidzana akasiyana zvakanyanya neaya eunidirectional laminates, uye nzira yekuwedzera yakanyanya kuoma. Vatsvakurudzi vane zvidzidzo zvishomanana zvekuedza pa-multi-directional laminates, uye kutsunga kwekuoma kwe interlaminar fracture haisati yatanga chiyero chepasi rose. Chikwata chekutsvagisa chakashandisa T700 uye T800 kabhoni faibha kugadzira akasiyana ecomposite laminates ane akasiyana interface layup angles, uye akadzidza pesvedzero yeinterface layup angle uye fiber bridging pane static uye kuneta delamination maitiro. Zvakaonekwa kuti fiber bridging inoumbwa neinoteedzera mupendero weiyo layer ine simba guru pakusimba kwe interlaminar fracture. Sezvo stratification ichiwedzera, iyo interlaminar kuputsika kusimba kuchawedzera zvishoma nezvishoma kubva kune yakaderera kukosha kwekutanga, uye kana iyo stratification inosvika kune imwe urefu hurefu, inosvika kune yakagadzikana kukosha, ndiko kuti, R resistance curve phenomenon. Iko kwekutanga kuputsika kusimba kweiyo interlayer kunenge kuenzana uye kunenge kuenzana nekuputsika kusimba kweresin, zvinoenderana nekuputsika kusimba kwematrix pachayo.[5, 6]. Nekudaro, iyo interlaminar fracture toughness yekuwedzera kukosha kweakasiyana interfaces anosiyana zvakanyanya. Yakakosha interface layer angle kutsamira inoratidzwa. Mukupindura kutsamira uku, Zhao et al.[5]zvichibva pamaitiro emuviri weiyo stratified resistance source, inofungidzirwa kuti interlaminar fracture toughness value value ine zvikamu zviviri, chikamu chimwe ibasa rekutyoka reiyo isina hukama layer interface, uye imwe chikamu intralayer kukuvara uye fiber. Basa rekutsemuka kunokonzerwa nebhiriji. Kuburikidza neinogumira chekuongorora chenzvimbo yekushushikana yekumberi kweiyo yakaturikidzana kumberi, inowanikwa kuti chikamu chechipiri chebasa rekutsemuka chinoenderana nekudzika kwenzvimbo yekukuvadza yepamberi (sezvinoratidzwa muMufananidzo 3), uye kudzika kwenzvimbo yekukuvadza inoenderana neiyo interface layup angle. A theoretical model yeI-type fracture toughness value value inoratidzwa ne sinusoidal function ye interface layer angle inoratidzwa.

Gong et al.[7]akaita iyo I/II hybrid stratification bvunzo pasi peakasiyana musanganiswa ratios, uye akawana kuti I/II hybrid stratification mu laminate zvakare ine akakosha R kuramba curve maitiro. Kuburikidza nekuongororwa kwekuputsika kwekuoma pakati pezvimedu zvakasiyana-siyana zvekuedza, zvinowanikwa kuti kukosha kwekutanga uye kukosha kwakagadzikana kwe interlaminar fracture kuoma kwechikamu chekuedza kunowedzera zvakanyanya nekuwedzera kwehuwandu hwekusanganiswa. Mukuwedzera, iyo yekutanga uye yakagadzikana kuputsika kuoma kweiyo interlayer pasi pezviyero zvakasiyana-siyana zvekusanganiswa zvinogona kutsanangurwa neBK criterion.

Panyaya yekuneta stratification, yakakosha fiber bridging yakaonekwa zvakare panguva yekuyedzwa. Kuburikidza nekuongororwa kweiyo data rekuyedza, zvinoonekwa kuti kuneta delamination kuwedzera kwezvinhu zvinoumbwa kunokanganisa ne "resistance curve", kuitira kuti yechinyakare kuneta stratification yekuwedzera mwero modhi uye kukosha kwechikumbaridzo hazvichashande. Pahwaro hwekuongorora dzidziso, Zhang naPeng[4,8,9]yakaunza kuneta delamination yekuwedzera kuramba kuratidza simba rinodiwa kune kuneta delamination kuwedzera kwezvinhu zvinoumbwa, uyezve kurudzira iyo yakajairika strain simba. Chiyero chekuburitsa ndiko kuneta kwakagadziriswa chiyero chekuwedzera modhi uye kukosha kwechikumbaridzo cheiyo control paramita. Iko kushanda kweiyo modhi uye yakajairwa chikumbaridzo paramende inosimbiswa nemiedzo. Uyezve, Zhao et al.[3]yakanyatsotarisisa mhedzisiro yefiber bridging, stress ratio uye mutoro-mixing ratio pane kuneta stratification uye kuwedzera maitiro, uye yakamisa yakajairika kuneta stratified yekuwedzera mwero modhi tichifunga nezve pesvedzero yereshiyo yekushushikana. Kurongeka kweiyo modhi kwakasimbiswa nekuneta stratification bvunzo ine akasiyana stress ratios uye musanganiswa ratios. Kune huwandu hwemuviri hwekuneta kwakamisikidzwa kwekuwedzera kuramba mune yakajairwa kuneta kwakagadziriswa yekuwedzera mwero modhi, Gong et al.[1]kukurira kushaya simba kwemaitiro ekuverenga ayo anogona chete kuwana mashoma discrete data mapoinzi kuburikidza nekuyedza, uye kumisikidza kuneta kubva pane simba rekuona. Muenzaniso wekuongorora wekuverenga kwe stratified yakawedzerwa kuramba. Iyo modhi inogona kuona iyo yehuwandu kutsunga kwekuneta stratification uye kuwedzera kuramba, uye kupa tsigiro yedzidziso yekushandisa yeiyo yakajairwa yakajairwa kuneta stratified yekuwedzera mwero modhi.

Mufananidzo 1 stratified test device dhayagiramu

Mufananidzo 1 stratified test device dhayagiramu

Mufananidzo 2 Inter-layer fracture toughness R kuramba curve[5]

Mufananidzo 3 Yakaiswa inotungamira kumucheto kukuvara zone uye stratified yakawedzera morphology[5]

2. Numerical simulation study

Kuenzanisa kwenhamba yekuwedzera kwakaturikidzana chinhu chakakosha chekutsvagisa mundima yecomposite chimiro dhizaini. Kana uchifanotaura kutadza kwe delamination kwecomposite unidirectional laminates, iyo iripo stratification yekuwedzera maitiro inowanzo shandisa inogara interlaminar kuputsika kusimba seyakanyanya kuita parameter.[10], nekuenzanisa iyo crack tip simba rekuburitsa chiyero uye interlaminar kuputsika kuoma. Saizi yekuona kana layering iri kuwedzera. Nzira yekukundikana kwe-multi-directional laminates yakaoma[11,12], iyo inoratidzirwa nekukosha kweR resistance curves[5,13]. Iyo iripo yakaturikidzana yekuwedzera maitiro haitore chikamu ichi uye haishande kune simulation ye delamination maitiro efiber-containing bridged multidirectional laminates. Gong et al.[10, 13]yakavandudza iyo iripo stratified yekuwedzera maitiro uye yakakurudzirwa kuunza R kuramba curve mumaitiro, uye zvichibva pane izvi, yakamisa stratified yekuwedzera criter tichifunga nezvemhedzisiro yefiber bridging. Tsanangudzo uye mashandisirwo eiyo bilinear constitutive cohesive unit yakadzidzwa zvakarongeka nenzira dzenhamba, kusanganisira kuomarara kwekutanga, simba rekubatanidza, viscosity coefficient uye huwandu hushoma hwezvinhu munzvimbo yakabatana simba. Iyo inoenderana yakabatana unit parameter modhi yakamiswa. Chekupedzisira, kushanda uye kushanda kweiyo yakagadziridzwa yakaturikidzana yekuwedzera chiyero uye cohesive unit parameter modhi inosimbiswa neiyo static stratification bvunzo. Zvisineyi, maitiro akavandudzwa anogona kungo shandiswa kune imwe-dimensional layered simulations nekuda kwekutsamira kwenzvimbo uye kwete maviri kana matatu-dimensional hierarchical edzedzero. Kuti agadzirise dambudziko iri, munyori akawedzera kurudziro nyowani yetrilinear yakabatana simba inoumba ichifunga nezve fiber bridging.[14]. Hukama hwekuumbwa hunoenderana nehurongwa hwakaoma hwekuwedzera kubva kune microscopic maonero, uye hune zvakanakira zvezvakareruka paramita uye zvakajeka zvinorehwa nemuviri.

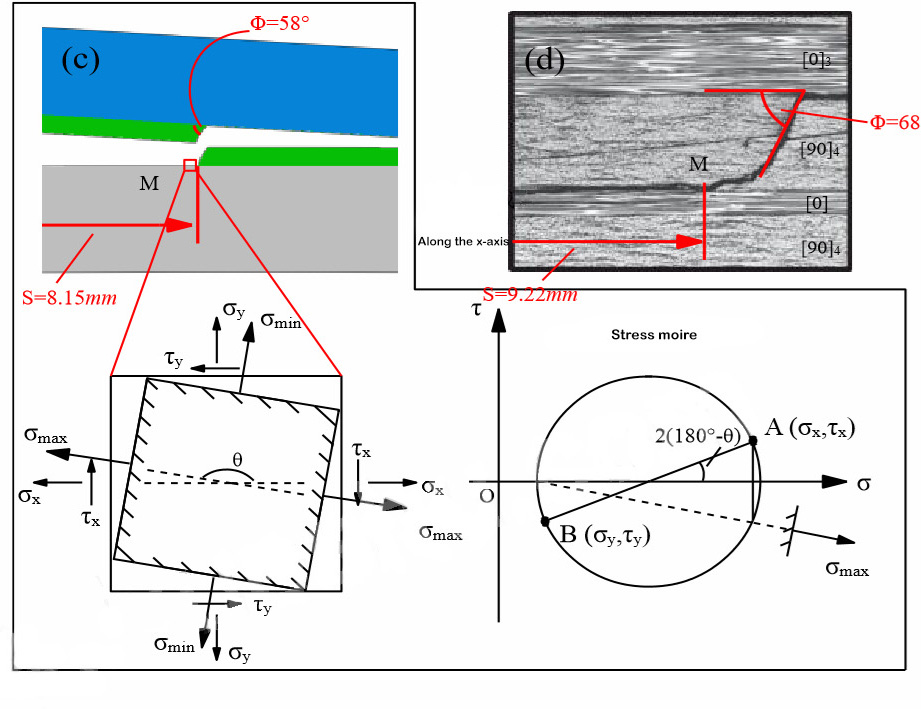

Uye zvakare, kuti unyatso kutevedzera iyo stratified migration phenomenon inowanzoitika mu stratification process ye-multi-directional laminates.[11,12], Zhao et al.[11,12]yakaronga yegwara rekutungamira modhi yakavakirwa pane yakawedzera magumo chinhu, kutevedzera yakakosha dhizaini. Hierarchical migration mune composite stratification bvunzo. Panguva imwecheteyo, modhi yekuwedzera yakaturikidzana inokurudzirwa maitiro ekuwedzera ezigzag pamwe ne90 ° / 90 ° layered interface, iyo inoteedzera nemazvo maitiro ekuwedzera e90 ° / 90 ° interface.

Mufananidzo 4 Numerical simulation ye layered migration uye miedzo yekuedza[15]

Mufananidzo 4 Numerical simulation ye layered migration uye miedzo yekuedza[15]

Mhedziso

Iri bepa rinotarisa patsvagurudzo yeboka iri mumunda wecomposite laminate delamination. Iwo ekuyedza maficha anonyanya kusanganisira pesvedzero yeiyo interface yekumisikidza angle uye fiber bridging pane iyo static uye kuneta delamination yekuwedzera maitiro. Kuburikidza nenhamba huru yezvidzidzo zvekuyedza, zvinoonekwa kuti iyo yakawanda-directional laminate yekutadza nzira yezvakaumbwa zvinhu zvakaoma. Fiber bridging ndiyo yakajairika kuomesera nzira yeakawanda-directional laminates, ndicho chikonzero chikuru cheR-resistance curve ye interlaminar fracture kuoma. Parizvino, iyo R kuramba curve kudzidza pasi peII stratification iri kushomeka uye inoda kumwe kutsvagisa. Kutanga kubva pakukundikana kwemashini, iyo yekuneta stratification modhi inosanganisira dzakasiyana-siyana zvinofurira zvinhu zvinokurudzirwa, inova kutungamira kwekuneta stratification yekutsvaga. Panyaya yekuenzanisa nhamba, boka rekutsvagisa rakakurudzira danho rakavandudzwa rekuwedzera uye yakabatana inomiririra modhi yekufunga nezve pesvedzero yefiber bridging pamaitiro ekuwedzera. Pamusoro pezvo, chinhu chakawedzerwa chinogumira chinoshandiswa kutevedzera zvirinani hierarchical migration phenomenon. Iyi nzira inobvisa kudiwa kweiyo yakanaka kupatsanurwa kwesero, kubvisa matambudziko ane chekuita ne mesh re-division. Iyo ine yakasarudzika mabhenefiti mukuenzanisa iyo stratification yezvimiro zvimiro, uye yakawanda engineering application yekutsvaga nzira iyi inodiwa mune ramangwana.[16].

References

[1] Y Gong, L Zhao, J Zhang, N Hu. Muenzaniso mutsva wekutarisa kuneta delamination kuramba mune composite laminates kubva pakuona kwesimba. Compos Sci Technol 2018; 167: 489-96.

[2] L Zhao, Y Wang, J Zhang, Y Gong, N Hu, N Li. XFEM-yakavakirwa modhi yekufananidza zigzag delamination kukura mune laminated composite pasi pe modhi yandinorodha. Compos Struct 2017; 160: 1155-62.

[3] L Zhao, Y Gong, J Zhang, Y Wang, Z Lu, L Peng, N Hu. Dudziro itsva yekuneta delamination kukura maitiro muCFRP multidirectional laminates. Compos Sci Technol 2016; 133:79-88.

[4] L Peng, J Zhang, L Zhao, R Bao, H Yang, B Fei. Mode I delamination kukura kwemultidirectional composite laminates pasi pekuneta kurodha. J Compost Mater 2011; 45: 1077-90.

[5] L Zhao, Y Wang, J Zhang, Y Gong, Z Lu, N Hu, J Xu. Iyo interface-inotsamira modhi yeplateau fracture kuomarara mune multidirectional CFRP laminates pasi modhi I kurodha. Composites Chikamu B: Engineering 2017; 131: 196-208.

[6] L Zhao, Y Gong, J Zhang, Y Chen, B Fei. Simulation yekukura kwe delamination mu multidirectional laminates pasi pe modhi I uye yakasanganiswa modhi I / II kurodha uchishandisa yakabatana zvinhu. Compos Struct 2014; 116:509-22.

[7] Y Gong, B Zhang, L Zhao, J Zhang, N Hu, C Zhang. R-curve maitiro eiyo yakasanganiswa-modhi I/II delamination mucarbon/epoxy laminates ine unidirectional uye multidirectional interfaces. Compos Struct 2019. (Pasi Ongororo).

[8] L Peng, J Xu, J Zhang, L Zhao. Yakasanganiswa modhi delamination kukura kweakawanda madirectional composite laminates pasi pekuneta kurodha. Eng Fract Mech 2012; 96: 676-86.

[9] J Zhang, L Peng, L Zhao, B Fei. Kuneta delamination kukura mazinga uye zvikumbaridzo zvecomposite laminates pasi pemusanganiswa mode kurodha. Int J Kuneta 2012; 40:7-15.

[10] Y Gong, L Zhao, J Zhang, Y Wang, N Hu. Delamination propagation criterion inosanganisira mhedzisiro yefiber bridging yemusanganiswa-modhi I/II delamination muCFRP multidirectional laminates. Compos Sci Technol 2017; 151:302-9.

[11] Y Gong, B Zhang, SR Hallett. Delamination migration mune multidirectional composite laminates pasi modhi I quasi-static uye kuneta kurodha. Compos Struct 2018; 189: 160-76.

[12] Y Gong, B Zhang, S Mukhopadhyay, SR Hallett. Ongororo yekudzidza pamusoro pe delamination migration mu multidirectional laminates pasi pe mode II static uye kuneta kurodha, nekuenzanisa nemaitiro I. Compos Struct 2018; 201: 683-98.

[13] Y Gong, L Zhao, J Zhang, N Hu. Iyo yakavandudzwa yemutemo mutemo weiyo delamination kuparadzira nemhedzisiro yehombe-mwero faibha bridging mucomposite multidirectional laminates. Compos Struct 2018; 184: 961-8.

[14] Y Gong, Y Hou, L Zhao, W Li, G Yang, J Zhang, N Hu. Inoveli mitatu-mutsara yakabatana zone modhi yekukura kwe delamination muDCB laminates ine mhedzisiro yefiber bridging. Compos Struct 2019. (Ichaendeswa)

[15] L Zhao, J Zhi, J Zhang, Z Liu, N Hu. XFEM simulation ye delamination mune composite laminates. Composites Chikamu A: Inoshandiswa Sayenzi uye Kugadzira 2016; 80: 61-71.

[16] Zhao Libin, Gong Yu, Zhang Jianyu. Kufambira mberi kwekutsvagisa pane stratified yekuwedzera maitiro efiber reinforced composite laminates. Chinyorwa cheAeronautical Sayenzi 2019: 1-28.

Kwakabva:Gong Yu, Wang Yana, Peng Lei, Zhao Libin, Zhang Jianyu.Chidzidzo pamusoro pe stratified expansion maitiro e advanced carbon fiber reinforced composite laminates[C]. Mechanics uye Injiniya - Numerical Computation uye Data Analysis 2019 Academic Musangano. Chinese Society of Mechanics, Beijing Mechanics Society, 2019. via ixueshu

Nguva yekutumira: Nov-15-2019