MANKHWALA NDI ENGINEERING - Numerical Computation and Data Analysis

Zimango ndi Umisiri - Kuwerengera Manambala ndi Kusanthula Kwa Data 2019 Msonkhano Wamaphunziro, Epulo 19-21, 2019, Beijing

Epulo 19-21, 2019, Beijing, China

Phunzirani pa Makhalidwe Okulitsa Osanjikiza a Advanced Carbon Fiber Yolimbitsa Mapepala Opangidwa ndi Laminates

Gong Yu1*, Wang Yana2, Peng Lei3, Zhao Libin4, Zhang Jianyu1

1Chongqing University, Chongqing, 400044, China

2China Aviation Research Institute Beijing Aeronautical Materials Research Institute, Beijing, 100095, China

3China Commercial Ndege Beijing Civil Aircraft Technology Research Center, Beijing, 102211, China

4Beijing University of Aeronautics and Astronautics, Beijing, 100191, China

NdemangaKapangidwe ka laminate ndi imodzi mwamakonzedwe ophatikizika omwe amagwiritsidwa ntchito kwambiri pazophatikizira, koma delamination imakhala njira yake yayikulu yolephera chifukwa cha kufooka kwa interlaminar. Kafukufuku wokhudza kusanjika kwa laminate ndi machitidwe okulitsa omwe amagwiritsidwa ntchito popanga uinjiniya nthawi zonse wakhala mutu wovuta kwambiri kwa akatswiri. Mu pepalali, zotsatira za kafukufuku wa carbon fiber reinforced composite delamination ku Chongqing University ndi Beijing University of Aeronautics and Astronautics Fatigue Fracture Laboratory amayambitsidwa kuchokera ku mbali ziwiri za kafukufuku woyesera ndi kuyerekezera manambala. Pomaliza, njira yachitukuko m'mundayo ikuyembekezeka.

Mawu osakira:carbon fiber analimbitsa gulu, laminate, delamination, kutopa stratification

mawu oyamba

Zipangizo zophatikizika zili ndi zinthu zabwino kwambiri monga mphamvu zenizeni komanso kuuma kwapadera, ndipo zakhala zikugwiritsidwa ntchito kwambiri muzamlengalenga, ukadaulo wamagetsi, komanso zoyendera ndi zomangamanga. Pakukonza ndi kugwiritsa ntchito zida zophatikizika, ulusi ndi matrix zimawonongeka mosiyanasiyana potengera katundu. Mitundu yolephera yodziwika bwino ya ma laminates ophatikizika amaphatikiza kuwonongeka kwa interlayer ndi kuwonongeka mkati mwa zigawo. Chifukwa cha kusowa kwa kulimbitsa mu njira ya makulidwe, mawonekedwe ozungulira a laminate ndi osauka, ndipo kuwonongeka kwa delamination kumakhala kosavuta kuchitika pansi pa katundu wakunja. Kuchitika ndi kukulira kwa kuwonongeka kwa stratified kumabweretsa kuchepa kwamphamvu ndi mphamvu zamapangidwe, komanso kuyambitsa ngozi zoopsa.[1-3]. Chifukwa chake, vuto la delamination limakhudzidwa kwambiri ndi kapangidwe kazinthu komanso kusanthula mphamvu kwa zida zophatikizika, ndipo ndikofunikira kuti muphunzire momwe mungakulitsire wosanjikiza wazinthu zophatikizika.[4].

Kufufuza pa khalidwe lakukula kwa laminate

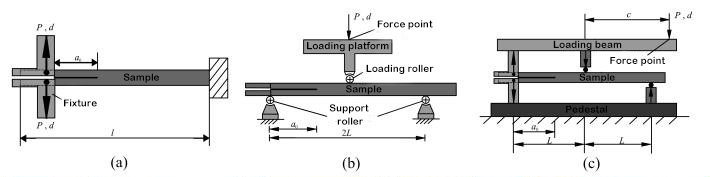

1. Kuphunzira moyesera

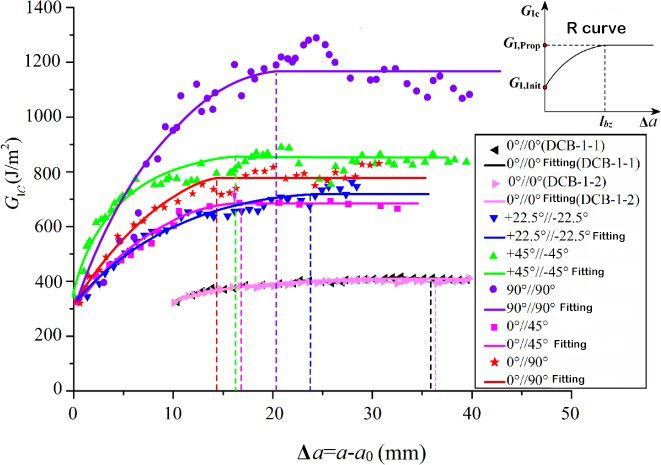

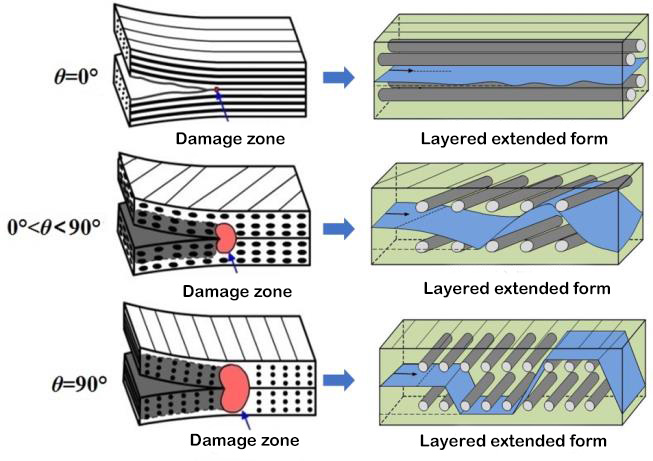

Interlaminar fracture toughness ndi mawonekedwe azinthu zamakina pakati pa zigawo zophatikiza. Miyezo yofananira yoyezetsa yakhazikitsidwa pofuna kutsimikizira kulimba kwa interlaminar fracture ya Type I, Type II ndi I/II hybrid unidirectional laminates. Zida zoyeserera zofananira zikuwonetsedwa mu Chithunzi 1. Komabe, ma laminates amitundu yambiri azinthu zophatikizika nthawi zambiri amagwiritsidwa ntchito muukadaulo weniweni. Chifukwa chake, kafukufuku woyesera pamachitidwe ophatikizika ndi kukulitsa kwa ma laminates amitundu yambiri ali ndi tanthauzo lofunikira kwambiri komanso uinjiniya. Mipikisano wosanjikiza laminate wosanjikiza kuyambika ndi kukulitsa kumachitika pakati pa ma interfaces okhala ndi ngodya zosanjikizana, ndipo machitidwe okulitsa osanjikiza amakhala osiyana kwambiri ndi a unidirectional laminates, ndipo njira yokulirapo imakhala yovuta kwambiri. Ochita kafukufuku ali ndi maphunziro ochepa oyesera pa ma laminates osiyanasiyana, ndipo kutsimikiza kwa kulimba kwa interlaminar fracture sikunakhazikitsebe muyezo wapadziko lonse lapansi. Gulu lofufuzalo linagwiritsa ntchito T700 ndi T800 carbon fiber kupanga mitundu yosiyanasiyana ya laminates yokhala ndi ma angles osiyanasiyana, ndipo adaphunzira momwe mawonekedwe a mawonekedwe amagwiritsidwira ntchito ndi kugwirizanitsa kwa fiber pa khalidwe la static ndi kutopa delamination. Zapezeka kuti kutsekeka kwa ulusi wopangidwa ndi mzere wotsatira wa wosanjikiza kumakhudza kwambiri kulimba kwa interlaminar fracture. Pamene stratification ikukulirakulira, kulimba kwa interlaminar fracture kumawonjezeka pang'onopang'ono kuchokera pamtengo wotsika woyambirira, ndipo pamene stratification ifika kutalika kwake, imafika pamtengo wokhazikika, ndiko kuti, R resistance curve phenomenon. Kulimba koyambirira kwa fracture ya interlayer ndi pafupifupi kofanana ndipo pafupifupi kofanana ndi kulimba kwa utomoni, zomwe zimatengera kulimba kwa matrix omwewo.[5, 6]. Komabe, ma interlaminar fracture toughness extensions of different interfaces amasiyana kwambiri. Kudalira kwakukulu kwa mawonekedwe osanjikiza ngodya kumaperekedwa. Poyankha kudalira uku, Zhao et al.[5]zochokera limagwirira thupi la stratified kukana gwero, amaona kuti interlaminar fracture kulimba kulimba mtengo tichipeza mbali ziwiri, gawo limodzi ndi fracture ntchito ya osagwirizana wosanjikiza mawonekedwe, ndi mbali ina ndi intralayer kuwonongeka ndi CHIKWANGWANI. Ntchito yosweka chifukwa cha bridging. Kupyolera mu malire a zinthu kusanthula kupanikizika kutsogolo kwa gawo la kutsogolo wosanjikiza, akupezeka kuti gawo lachiwiri la ntchito fracture zimadalira kuya kwa delamination kutsogolo kuwonongeka zone (monga momwe chithunzi 3), ndi kuya kwa zone kuwonongeka ndi molingana ndi mawonekedwe kusanja ngodya. Chitsanzo chongoyerekeza cha mtundu wa I-mtundu wa kulimba kulimba kwa mtengo wofotokozedwa ndi ntchito ya sinusoidal ya mawonekedwe osanjikiza ngodya imaperekedwa.

Gong et al.[7]adachita mayeso a hybrid stratification a I/II mosiyanasiyana mosakanikirana, ndipo adapeza kuti I/II hybrid stratification mu laminate ilinso ndi mawonekedwe a R kukana pamapindikira. Kupyolera mu kusanthula kulimba kwa fracture pakati pa zidutswa zosiyana zoyesera, zimapezeka kuti mtengo woyambirira ndi mtengo wokhazikika wa interlaminar fracture toughness ya testpiece imawonjezeka kwambiri ndi kuwonjezeka kwa chiŵerengero chosakanikirana. Kuphatikiza apo, kulimba kolimba kokhazikika komanso kokhazikika kwa interlayer pansi pazigawo zosiyanasiyana zosakanikirana kumatha kufotokozedwa ndi muyezo wa BK.

Pankhani ya stratification ya kutopa, kulumikizidwa kwakukulu kwa fiber kudawonedwanso pakuyesa. Kupyolera mu kusanthula kwa deta yoyesera, zikuwoneka kuti kutopa kwa delamination kukula kwa zinthu zophatikizika kumakhudzidwa ndi "resistance curve", kotero kuti chikhalidwe cha chikhalidwe cha kutopa stratification chiwonjezeko cha kukula ndi mtengo wapakati sizikugwiranso ntchito. Pamaziko a kusanthula chiphunzitso, Zhang ndi Peng[4,8,9]adayambitsa kukana kwakukula kwa kutopa kwa delamination kuti afotokoze mphamvu zomwe zimafunikira pakukulitsa kwapang'onopang'ono kwa zinthu zophatikizika, ndikuwonjezeranso mphamvu yokhazikika yokhazikika. Mtengo wotulutsidwa ndi mtundu wokulirapo wa kutopa wokhazikika komanso kuchuluka kwa magawo owongolera. Kugwiritsa ntchito kwachitsanzo ndi gawo lokhazikika lokhazikika kumatsimikiziridwa ndi kuyesa. Komanso, Zhao et al.[3]anaganizira mozama zotsatira za fiber bridging, chiŵerengero cha kupsinjika maganizo ndi chiŵerengero cha kusakanizika kwa katundu pa kutopa kwa stratification ndi kachitidwe kakukulirakulira, ndikukhazikitsa njira yokhazikika ya kutopa yokhazikika poganizira mphamvu ya chiŵerengero cha kupsinjika maganizo. Kulondola kwachitsanzocho kunatsimikiziridwa ndi kuyesa kwa kutopa kwa stratification ndi zosiyana zosiyana za kupsinjika maganizo ndi kusakaniza kusakaniza. Pakuchulukirachulukira kwa kutopa komwe kumayenderana ndi kukana kukulirakulira mumtundu wokhazikika wa kutopa wokhazikika, Gong et al.[1]gonjetsani kufooka kwa njira yowerengera yomwe ingangopeza mfundo zochepa za data kudzera muzoyesera, ndikukhazikitsa kutopa kuchokera pamalingaliro amphamvu. Chitsanzo chowunikira cha kuwerengera kwa stratified extended resistance. Chitsanzochi chikhoza kuzindikira kutsimikiza kwa kuchuluka kwa kutopa ndi kukana kukula, ndikupereka chithandizo chamaganizo pakugwiritsa ntchito njira yowonjezereka ya kutopa yokhazikika.

Chithunzi 1 stratified test device diagram

Chithunzi 1 stratified test device diagram

Chithunzi 2 Pakati-wosanjikiza fracture kulimba R kukana curve[5]

Chithunzi 3 Zowonongeka zotsogola zam'mphepete ndi mawonekedwe okulirapo[5]

2. Kayeseleledwe ka manambala

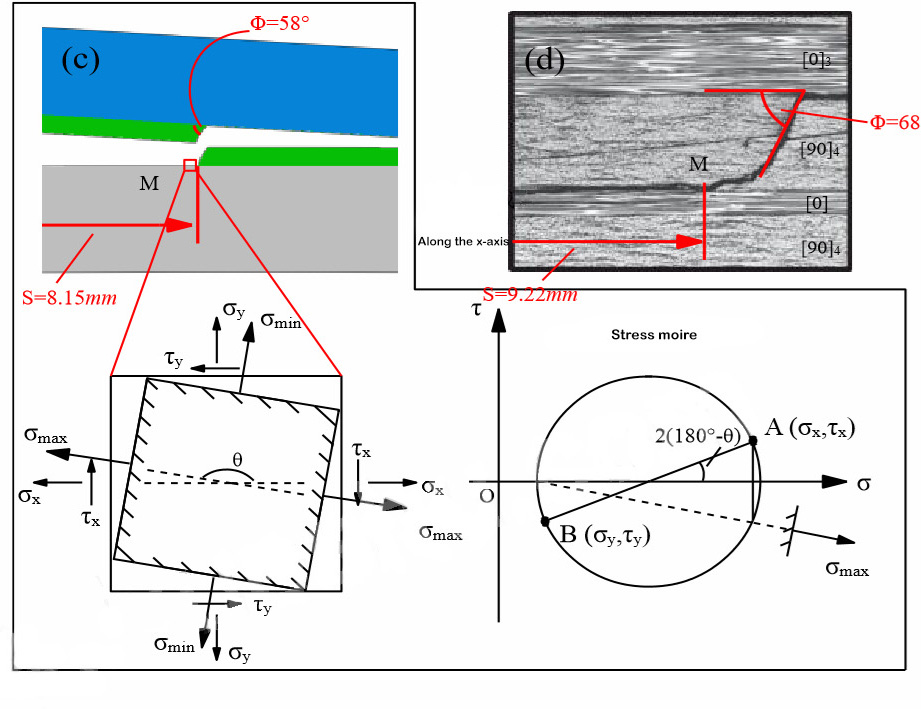

Kuyerekeza kwa manambala kwa kukulitsa kwakusanjikiza ndi chinthu chofunikira kwambiri pa kafukufuku wamapangidwe amitundu yosiyanasiyana. Polosera za kulephera kwa delamination kwa composite unidirectional laminates, njira zokulirapo za stratification zomwe zilipo nthawi zambiri zimagwiritsa ntchito kulimba kwapakati pa interlaminar ngati gawo loyambira.[10], poyerekezera kuchuluka kwa mphamvu yotulutsa mphamvu ya crack nsonga ndi kulimba kwa interlaminar fracture. Kukula kuti muwone ngati layering ikukulirakulira. Njira yolephera ya laminates yamitundu yambiri ndi yovuta[ 11, 12 ], yomwe imadziwika ndi ma curve ofunika kwambiri a R[5,13]. Njira zokulirapo zomwe zilipo sizikuganiziranso mbaliyi ndipo sizikugwira ntchito poyerekezera ndi khalidwe la delamination la fiber-containing bridged multidirectional laminates. Gong et al.[ 10, 13 ]adawongolera njira zokulirapo zomwe zidalipo ndipo adaganiza zoyambitsa njira yolimbikitsira ya R munjirazo, ndipo potengera izi, adakhazikitsa njira yokulirapo ya stratified poganizira zotsatira za kulumikiza kwa fiber. Tanthauzo ndi magawo ogwiritsira ntchito magawo awiri ophatikizika ophatikizana adawerengedwa mwadongosolo ndi njira zamawerengero, kuphatikiza kuuma kwa mawonekedwe, mphamvu ya mawonekedwe, kukhuthala kwamphamvu komanso kuchuluka kwa zinthu zomwe zili mugawo lamphamvu. Mtundu wofananira wagawo logwirizana unakhazikitsidwa. Pomaliza, kugwira ntchito ndi kutheka kwa mulingo wokulirapo wosanjikiza ndi mtundu wolumikizana wagawo wagawo zimatsimikiziridwa ndi kuyesa kwa static stratification. Komabe, njira zowongoleredwa zitha kugwiritsidwa ntchito poyerekezera ndi mbali imodzi yokha chifukwa cha kudalira kwa malo osati pazowonjezera zamitundu iwiri kapena itatu. Kuti athetse vutoli, wolemba adaperekanso lingaliro latsopano lamphamvu logwirizana la trilinear lomwe liyenera kukhazikitsidwa poganizira kulumikiza kwa fiber.[14]. Ubale wokhazikika umagwirizana ndi njira yovuta yokulirakulira pang'onopang'ono kuchokera ku kawonedwe kakang'ono, ndipo uli ndi ubwino wa magawo osavuta komanso tanthauzo lomveka bwino la thupi.

Kuonjezera apo, pofuna kutsanzira molondola stratified migration chodabwitsa chofala mu stratification ndondomeko ya multidirectional laminates.[ 11, 12 ], Zhao et al.[ 11, 12 ]adakonza njira yowongolera njira yopitilira muyeso yokhazikika, kutengera kapangidwe kapadera. Kusamuka kwa hierarchical mu mayeso a composite stratification. Panthawi imodzimodziyo, njira yowonjezera yowonjezera ikukonzedwa kuti ikhale ndi machitidwe okulitsa a zigzag motsatira 90 °/90 ° mawonekedwe osanjikiza, omwe amatsanzira molondola kachitidwe kakufalikira kwa mawonekedwe a 90 °/90 °.

Chithunzi 4 Nambala kayeseleledwe ka kusamuka kosanjikiza ndi zotsatira zoyesera[15]

Chithunzi 4 Nambala kayeseleledwe ka kusamuka kosanjikiza ndi zotsatira zoyesera[15]

Mapeto

Pepalali likuyang'ana zotsatira za kafukufuku wa gulu ili m'munda wa composite laminate delamination. Magawo oyesera amaphatikizanso kukhudzidwa kwa mawonekedwe a mawonekedwe a mawonekedwe ndi kutsekeka kwa fiber pamayendedwe okulirapo komanso kutopa kwa delamination. Kupyolera mu maphunziro ambiri oyesera, amapezeka kuti njira yolephereka yamitundu yambiri ya laminate ya zipangizo zophatikizika ndizovuta. Kutsekera kwa ulusi ndi njira yolimbikitsira yamitundu yosiyanasiyana, yomwe ndi chifukwa chachikulu cha R-resistance curve ya interlaminar fracture toughness. Pakalipano, kafukufuku wa R resistance curve pansi pa II stratification akusowa ndipo akusowa kufufuza kwina. Kuyambira pamakina olephera, mtundu wa kutopa wokhazikika kuphatikiza zinthu zingapo zokokera zikuperekedwa, zomwe ndi njira ya kafukufuku wa kutopa. Pankhani yoyerekeza manambala, gulu lofufuza lidapereka njira yopititsira patsogolo yaukadaulo komanso njira yolumikizirana yogwirizana kuti iganizire za kukhudzika kwa fiber pamayendedwe okulirakulira. Kuphatikiza apo, chinthu chowonjezera chamalire chimagwiritsidwa ntchito kutsanzira bwino zochitika zakusamuka kwa hierarchical. Njirayi imathetsa kufunika kogawanitsa bwino maselo, kuthetsa mavuto okhudzana ndi kugawanitsanso mauna. Ili ndi maubwino apadera potengera kusanja kwa mawonekedwe osagwirizana, ndipo kafukufuku wochulukirapo waukadaulo wa njirayi akufunika mtsogolo.[16].

Maumboni

[1] Y Gong, L Zhao, J Zhang, N Hu. Chitsanzo chodziwika bwino chodziwira kutopa kwa delamination kukana mu composite laminates kuchokera ku mphamvu. Compos Sci Technol 2018; 167: 489-96.

[2] L Zhao, Y Wang, J Zhang, Y Gong, N Hu, N Li. Chitsanzo chokhazikitsidwa ndi XFEM chofanizira kukula kwa zigzag delamination m'magulu opangidwa ndi laminated pansi pamayendedwe omwe ndimatsitsa. Compos Struct 2017; 160: 1155-62.

[3] L Zhao, Y Gong, J Zhang, Y Wang, Z Lu, L Peng, N Hu. Kutanthauzira kwaposachedwa kwamayendedwe otopa a delamination kukula mu CFRP multidirectional laminates. Compos Sci Technol 2016; 133:79-88 .

[4] L Peng, J Zhang, L Zhao, R Bao, H Yang, B Fei. Mode I delamination kukula kwa multidirectional composite laminates pansi kutopa Kutsegula. J Compost Mater 2011; 45: 1077-90.

[5] L Zhao, Y Wang, J Zhang, Y Gong, Z Lu, N Hu, J Xu. Mtundu wodalira mawonekedwe a kulimba kwa kuphulika kwa mapiri mumitundu yosiyanasiyana ya CFRP laminates pansi pa mode I potsegula. Composites Gawo B: Engineering 2017; 131: 196-208.

[6] L Zhao, Y Gong, J Zhang, Y Chen, B Fei. Kuyerekezera kwa kukula kwa delamination mu multidirectional laminates pansi pa mode I ndi kusakaniza kwa I/II modes pogwiritsa ntchito zinthu zogwirizana. Compos Struct 2014; 116: 509-22 .

[7] Y Gong, B Zhang, L Zhao, J Zhang, N Hu, C Zhang. Makhalidwe a R-curve a delamination-mode I/II delamination mu kaboni/epoxy laminates okhala ndi unidirectional and multidirectional interfaces. Compos Struct 2019. (Kuwunikiridwa).

[8] L Peng, J Xu, J Zhang, L Zhao. Kukula kosakanikirana kwa delamination kwa multidirectional composite laminates pansi pa kutopa. Eng Fract Mech 2012; 96: 676-86.

[9] J Zhang, L Peng, L Zhao, B Fei. Kutopa kwa delamination kukula mitengo ndi malire a kompositi laminates pansi osakaniza mode Kutsegula. Int J Kutopa 2012; 40:7-15 .

[10] Y Gong, L Zhao, J Zhang, Y Wang, N Hu. Mulingo wofalitsa wa Delamination kuphatikiza momwe fiber bridging imagwirira ntchito mosakanikirana I/II delamination mu CFRP multidirectional laminates. Compos Sci Technol 2017; 151: 302-9 .

[11] Y Gong, B Zhang, SR Hallett. Kusamuka kwa Delamination mu multidirectional composite laminates pansi pa mode I quasi-static ndi kutopa Kutsegula. Compos Struct 2018; 189: 160-76 .

[12] Y Gong, B Zhang, S Mukhopadhyay, SR Hallett. Kafukufuku woyeserera pa kusamuka kwa delamination mumitundu yambiri yama laminates pansi pa mode II static ndi kutopa kutsitsa, poyerekeza ndi mode I. Compos Struct 2018; 201: 683-98.

[13] Y Gong, L Zhao, J Zhang, N Hu. Mulingo wotsogola wa malamulo amphamvu pakufalitsa kwa delamination ndi zotsatira za bridging yayikulu ya fiber mu composite multidirectional laminates. Compos Struct 2018; 184: 961-8.

[14] Y Gong, Y Hou, L Zhao, W Li, G Yang, J Zhang, N Hu. Mtundu watsopano wa mizere itatu yolumikizana pakukula kwa delamination mu DCB laminates ndi zotsatira za fiber bridging. Compost Struct 2019. (Iziperekedwa)

[15] L Zhao, J Zhi, J Zhang, Z Liu, N Hu. XFEM kayeseleledwe ka delamination mu composite laminates. Composites Gawo A: Sayansi Yogwiritsidwa Ntchito ndi Kupanga 2016; 80: 61-71 .

[16] Zhao Libin, Gong Yu, Zhang Jianyu. Kafukufuku akupita patsogolo pakukula kwa stratified kwa fiber reinforced composite laminates. Journal of Aeronautical Sciences 2019: 1-28.

Gwero:Gong Yu, Wang Yana, Peng Lei, Zhao Libin, Zhang Jianyu.Kafukufuku wa stratified exturated behavior of advanced carbon fiber reinforced composite laminates[C]. Mechanics and Engineering - Numerical Computation and Data Analysis 2019 Academic Conference. Chinese Society of Mechanics, Beijing Mechanics Society, 2019. kudzera ife

Nthawi yotumiza: Nov-15-2019