Carbon fiber ke inorganic polymer fiber inorganic material e ncha e nang le khabone e kaholimo ho 95%, e nang le letsoalo le tlase, matla a phahameng, ho hanyetsa mocheso o phahameng, botsitso ba lik'hemik'hale, ho thibela mokhathala, ho sesa le lisebelisoa tse ling tse ntle tsa 'mele le lik'hemik'hale,' me e na le ts'ebetso e phahameng ea ho sisinyeha, conductivity e ntle ea mocheso, ts'ebetso ea ts'ireletso ea motlakase le likarolo tse ling tse tlase tsa mocheso. Thepa ena e babatsehang e etsa hore carbon fiber e sebelisoe haholo sebakeng sa lifofane, lipalangoang tsa terene, tlhahiso ea likoloi, libetsa le lisebelisoa, mechine ea kaho, kaho ea mehaho ea motheo, boenjiniere ba leoatle, boenjiniere ba peterole, matla a moea, thepa ea lipapali le likarolo tse ling.

Ho ipapisitsoe le litlhoko tsa maano a naha tsa lisebelisoa tsa carbon faeba, China e e thathamisitse e le e 'ngoe ea litheknoloji tsa mantlha tsa liindasteri tse ntseng li hlaha tse shebaneng le tšehetso. Ho moralo oa naha oa "Leshome le metso e 'meli" la Saense le thekenoloji, boitokisetso le thekenoloji ea ts'ebeliso ea ts'ebetso e phahameng ea k'habone fiber ke e' ngoe ea litheknoloji tsa mantlha tsa liindasteri tse hlahang tsa maano tse tšehetsoang ke mmuso. May 2015, Lekhotla la Naha ka molao le lokollotsoe "Made in China 2025", thepa e ncha e le e 'ngoe ea libaka tse ka sehloohong tsa ts'ebetso e matla le nts'etsopele, ho kenyeletsoa lisebelisoa tse phahameng tsa sebopeho, li-composites tse tsoetseng pele ke sepheo sa tsoelo-pele tšimong ea thepa e ncha. Ka Mphalane 2015, Lekala la Indasteri le Indasteri ea Boitsebiso le ile la phatlalatsa ka molao "China Manufacturing 2025 key Areas Technology Roadmap", "fiber e sebetsang hantle le likarolo tsa eona" e le ntho e ka sehloohong ea leano, sepheo sa 2020 ke "lihlopha tsa carbon fiber tsa malapeng ho finyella litlhoko tsa tekheniki tsa lifofane tse kholo le lisebelisoa tse ling tsa bohlokoa." November 2016, Lekhotla la Naha le ile la ntša "leshome le metso e mehlano" naha "Leshome le metso e mehlano" moralo oa naha, Strategic hlahellang Industries Development moralo, ka ho hlaka o ile a bontša ho matlafatsa indasteri e ncha ea lintho tse bonahalang tshehetso tšebelisano-'moho holimo le tlaase molapo, ka lik'habone faeba metsoako le masimo a mang ho phetha kopo ea tšebelisano-'moho pontšo pilot, ho haha tšebelisano-'moho kopo sethaleng. Ka January 2017, Lekala la Indasteri le Ntšetso-pele, NDRC, saense le thekenoloji, le Lekala la Lichelete ba kopanetse "Tataiso ho nts'etsopele ea liindasteri tse ncha tsa thepa", 'me ba etsa tlhahiso ea hore ho tloha ka 2020, "ka carbon fiber composite, boleng bo phahameng ba tšepe e khethehileng, lisebelisoa tse tsoetseng pele tsa alloy le masimo a mang ho finyella ho feta 70 ts'ebetsong ea ts'ebetso ea lisebelisoa tse ncha, ts'ebetso ea ts'ebetso ea lisebelisoa tse ncha tsa lisebelisoa tsa thepa ea thepa ea thepa ea thepa ea thepa ea thepa ea thepa ea thepa ea thepa e ncha. indasteri e ncha ea thepa.

Hobane carbon fiber le likarolo tsa eona li na le karolo ea bohlokoa ts'ireletsong ea naha le boiphelisong ba Batho, litsebi tse ngata li shebana le nts'etsopele ea tsona le tlhahlobo ea mekhoa ea lipatlisiso. Dr. Zhou Hong o ile a hlahloba litlatsetso tsa mahlale le thekenoloji tse entsoeng ke bo-ramahlale ba Amerika methating ea pele ea nts'etsopele ea theknoloji ea carbon fiber e sebetsang hantle, 'me a hlahloba le ho tlaleha ka lits'ebetso tse kholo tse 16 le tsoelo-pele ea morao-rao ea theknoloji ea carbon fiber, le theknoloji ea tlhahiso, thepa le ts'ebeliso ea polyacrylonitrile carbon fiber le tsoelo-pele ea eona ea morao-rao ea thekenoloji e ile ea hlahlojoa ke mathata a teng, joalo-joalo. ntshetsopeleng ya carbon faeba Chaena. Ho feta moo, batho ba bangata ba entse lipatlisiso mabapi le tlhahlobo ea metrology ea lipampiri le litokelo tsa molao lefapheng la carbon fiber le metsoako ea eona. Ka mohlala, Ma Xianglin le ba bang ho tloha ponong ea metrology ho tloha ka 1998-2017 carbon fiber patent kabo le ts'ebeliso ea tšimo ea tlhahlobo; Yang Sisi le ba bang ba ipapisitse le sethala sa innograph bakeng sa patlo ea lefatše ka bophara ea carbon fiber patent le lipalo-palo tsa data, ho tloha moetlong oa selemo le selemo oa nts'etsopele ea litokelo tsa litokelo tsa molao, litokelo tsa molao, Hotspot ea theknoloji ea patent le patent ea mantlha ea theknoloji e hlahlojoa.

Ho ea ka pono ea k'habone faeba ho etsa lipatlisiso le ntshetsopele trajectory, ho etsa lipatlisiso China hoo e ka bang synchronized le lefatše, empa ntshetsopeleng butle, phahameng-tshebetso k'habone faeba tlhahiso ea tekanyo le boleng bapisoa le linaha tse ling na le lekhalo, ho na le ke tlhokahalo e potlakileng ho potlakisa R & amp; d ts'ebetso, ho ntšetsa pele moralo oa leano, ho nka monyetla oa ntlafatso ea indasteri ea nako e tlang. Ka hona, pampiri ena e batlisisa pele moralo oa morero oa linaha tse tšimong ea lipatlisiso tsa carbon fiber, e le ho utloisisa moralo oa R & amp; d litsela linaheng tse fapa-fapaneng, 'me ea bobeli, hobane lipatlisiso tsa motheo le kopo ea kopo ea carbon fiber ke ea bohlokoa haholo bakeng sa lipatlisiso tsa botekgeniki le nts'etsopele ea carbon fiber, ka hona, Re etsa tlhahlobo ea metrology ho tsoa ho liphetho tsa lipatlisiso tsa thuto-SCI le ho sebelisa liphetho tsa lipatlisiso-patent ka nako e le 'ngoe ho fumana kutloisiso e pharaletseng ea R & amp; d tsoelo-pele tšimong ea carbon faeba, le ho scan ninemanga.com dipatlisiso tsa moraorao ntshetsopeleng sebakeng sena ho Peep International Frontier R & amp; d tsoelopele. Qetellong, ho ipapisitsoe le liphetho tsa lipatlisiso tse kaholimo, litlhahiso tse ling tsa tsela ea lipatlisiso le nts'etsopele lefapheng la carbon fiber naheng ea China li behiloe pele.

2.Cfiber ea arbonmoralo oa morero oa lipatlisiso oalinaha/libaka tse kholo

Linaha tse ka sehloohong tsa tlhahiso ea carbon fiber li kenyelletsa Japane, United States, Korea Boroa, linaha tse ling tsa Europe le Taiwan, Chaena. Linaha tsa thekenoloji e tsoetseng pele qalong ea tsoelo-pele ea theknoloji ea carbon faeba e hlokometse bohlokoa ba thepa ena, e entse moralo oa leano, e khothalletsa ka matla nts'etsopele ea lisebelisoa tsa carbon faeba.

2.1 Japane

Japane ke naha e tsoetseng pele ka ho fetisisa bakeng sa theknoloji ea carbon fiber. Likhamphani tse 3 tsa Toray, Bong le Mitsubishi Liyang tsa Japane li nka karolo ea 70% ~ 80% ea 'maraka ea lefats'e ea tlhahiso ea fiber ea carbon. Leha ho le joalo, Japane e nka bohlokoa bo boholo ba ho boloka matla a eona tšimong ena, haholoholo nts'etsopele ea li-pan-based fiber fibers le matla le theknoloji e baballang tikoloho, ka tšehetso e matla ea batho le ea lichelete, le ka maano a mangata a mantlha, ho kenyeletsoa leano la mantlha la matla, moralo oa leano la kholo ea moruo le Protocol ea Kyoto. E ipapisitse le Leano la mantlha la matla a naha le Leano la Tikoloho, Lekala la Moruo, indasteri le thepa ea Japane e behile "Lenaneo la Lipatlisiso tsa Theknoloji ea ho boloka Matla le Lenaneo la Nts'etsopele". E tšehetsoa ke leano le ka holimo, indasteri ea carbon fiber ea Japane e khonne ho kenya likarolo tsohle tsa lisebelisoa le ho khothalletsa tharollo ea mathata a tloaelehileng indastering ea carbon fiber.

"Ntšetso-pele ea theknoloji e kang lisebelisoa tse ncha tsa meralo" (2013-2022) ke morero o kentsoeng tlas'a "Project Development Research Project" Japane ho finyella haholo nts'etsopele ea theknoloji e hlokahalang ea thepa ea thepa le ho kopanya lisebelisoa tse fapaneng, ka sepheo sa mantlha sa ho fokotsa boima bo bobebe (halofo ea boima ba koloi) ea lipalangoang. 'Me qetellong hlokomela ts'ebeliso ea eona e sebetsang. Ka mor'a ho nka mosebetsi oa ho etsa lipatlisiso le nts'etsopele ka 2014, Setsi sa Ntšetso-pele ea Theknoloji ea Liindasteri (NEDO) se ile sa hlahisa li-subprojects tse 'maloa tseo ho tsona sepheo sa kakaretso sa morero oa lipatlisiso tsa carbon Fiber "Innovative carbon fiber basic research and development" e ne e le: ho hlahisa metsoako e mecha ea carbon fiber precursor; ho hlakisa mokhoa oa ho theha mekhoa ea carbonization; le ho ntshetsapele le ho tiisa mekgwa ya tekolo ya carbon faeba. Morero, o etelletsoeng pele ke Univesithi ea Tokyo 'me o kopanetse Setsi sa Theknoloji ea Liindasteri (NEDO), Toray, Teijin, Dongyuan, le Mitsubishi Liyang, o entse tsoelo-pele e kholo ka Pherekhong 2016 mme ke katleho e' ngoe e kholo lefapheng la pan-based carbon fiber kamora ho qaptjoa ha "Kondo mode" Japane ka 1959.

2.2 United States

Setsi sa Patlisiso ea Ts'ireletso ea Amerika (DARPA) se ile sa tsebahatsa projeke ea Advanced Structural Fiber ka 2006 ka sepheo sa ho kopanya sehlopha se seholo sa naha sa lipatlisiso tsa mahlale ho nts'etsapele likhoele tsa sebopeho sa moloko o latelang tse thehiloeng holim'a likhoele tsa khabone. E tšehelitsoe ke morero ona, sehlopha sa lipatlisiso sa Setsi sa Theknoloji sa Georgia se United States se ile sa phunyeletsa theknoloji ea ho lokisa terata e tala ka 2015, sa eketsa modulus ea eona ea elastic ka 30%, e tšoaea United States ka matla a nts'etsopele ea moloko oa boraro oa carbon fiber.

Ka 2014, Lefapha la Matla la United States (DOE) le phatlalalitse lithuso tsa lidolara tse limilione tse 11.3 bakeng sa merero e 'meli e mabapi le "mehato e mengata e thusang ho fetola tsoekere e sa jeoang hore e be acrylonitrile" le "lipatlisiso le ntlafatso ea acrylonitrile e nkiloeng ho tsoa ho biomass ts'ebeliso ea lihlahisoa tsa temo" ho nts'etsapele ts'ebeliso ea theko e tlase. lisebelisoa tse phahameng tsa carbon faeba bakeng sa tlhahiso ea lisebelisoa tse ka nchafatsoang tse se nang lijo, joalo ka biomass e entsoeng ka lehong, 'me e rera ho fokotsa litšenyehelo tsa tlhahiso ea biomass e ka nchafatsoang likhoele tsa khabone ho tlase ho $5/lb ka 2020.

Ka March 2017, Lefapha la Matla a United States le ile la boela la phatlalatsa liranta tse limilione tse 3,74 ka lichelete tsa "carbon fiber component R & amp; d project" e etelletsoeng ke Western American Institute (WRI), e shebaneng le nts'etsopele ea likarolo tse tlaase tsa carbon fiber tse thehiloeng mehloling e kang mashala le biomass.

July 2017, Lefapha la Matla a United States le phatlalalitse lichelete tsa liranta tse limilione tse 19.4 ho tšehetsa lipatlisiso le nts'etsopele ea likoloi tse tsoetseng pele tse sebetsang hantle, tse limilione tse 6.7 tse sebelisetsoang ho tšehetsa ho lokisoa ha carbon fibers e theko e tlaase e sebelisa lisebelisoa tsa computational, ho akarelletsa le nts'etsopele ea mekhoa e mengata ea tlhahlobo ea theknoloji ea k'homphieutha e kopantsoeng ho hlahloba cheseho e tsoetseng pele ea li-molek'hule tsa k'habone. khopolo-taba, ho ithuta ka mochine le lisebelisoa tse ling li sebelisetsoa ho hlahisa lisebelisoa tsa morao-rao tsa k'homphieutha ho ntlafatsa katleho ea khetho ea thepa e tlaase ea carbon fiber.

2.3 Europe

Indasteri ea k'habone ea Europe e ntlafalitsoeng Japane le United States lilemong tsa bo-Seventies kapa mashome a robeli a lekholo la bo20 la lilemo, empa ka lebaka la thekenoloji le chelete e ngata, lik'hamphani tse ngata tse hlahisang fiber e le 'ngoe ha lia ka tsa latela nako ea kholo e phahameng ea tlhoko ea carbon fiber kamora lilemo tse 2000 mme ea nyamela, Khamphani ea Jeremane SGL ke eona feela k'hamphani Europe e bileng le karolo e kholo 'marakeng oa lefatše oa carbon fiber.

Ka Pulungoana 2011, European Union e ile ea thakhola Morero oa Eucarbon, o ikemiselitseng ho ntlafatsa bokhoni ba tlhahiso ea Europe ka carbon fiber le lisebelisoa tse kentsoeng pele bakeng sa sefofane. Morero o ile oa nka lilemo tse 4, ka letsete le felletseng la li-euro tse limilione tse 3,2, 'me ka May 2017 ka katleho ho thehile mohala oa pele oa tlhahiso ea k'habone e khethehileng ea Europe bakeng sa lits'ebetso tsa sebaka tse kang li-satellites, ka hona ho nolofalletsa Europe ho tloha ho its'etleha ho tsoa ho sehlahisoa le ho netefatsa polokeho ea phepelo ea thepa.

EU Seventh Framework e rera ho ts'ehetsa "carbon fiber e sebetsang ha ho lokisoa sistimi e ncha ea pele e nang le ts'ebetso e theko e boima le e laolehang" (FIBRALSPEC) projeke (2014-2017) ka li-euro tse limilione tse 6.08. Morero oa lilemo tse 4, o etelletsoeng pele ke National Technical University of Athene, Greece, ka ho kenya letsoho ha lik'hamphani tsa machaba tse kang Italy, United Kingdom le Ukraine, li tsepamisitse maikutlo ho nts'etsopele le ho ntlafatsa ts'ebetso ea ho tsoela pele ho lokisoa ha likhoele tsa carbon tse thehiloeng ho polyacrylonitrile ho fihlela tlhahiso ea liteko ea li-pan-based carbon fibers tse tsoelang pele. Morero o phethetse ka katleho nts'etsopele le ts'ebeliso ea carbon fiber le theknoloji e ntlafalitsoeng ea motsoako ho tsoa mehloling ea polymer e ka nchafatsoang (joalo ka li-supercapacitor, matlo a ts'ireletso a potlakileng, hammoho le mochini o roalang motlakase oa mochini oa prototype le nts'etsopele ea mela ea tlhahiso ea li-nanofibers, jj.).

Palo e ntseng e hola ea likarolo tsa indasteri, joalo ka likoloi, matla a moea le kaho ea likepe, e hloka lisebelisoa tse bobebe, tse sebetsang hantle haholo, e leng 'maraka o moholo o ka bang teng bakeng sa indasteri ea carbon fiber. EU e tsetela li-euro tse limilione tse 5.968 ho qala projeke ea Carboprec (2014-2017), sepheo sa leano e leng ho nts'etsapele li-precursor tsa theko e tlase ho tsoa lisebelisoa tse nchafalitsoeng tse teng hohle Europe le ho ntlafatsa tlhahiso ea likhoele tsa khabone tse sebetsang hantle ka carbon nanotubes.

Lenaneo la lipatlisiso la European Union la Cleansky II le tšehelitse ka lichelete morero oa "Composite tire R & amp; d" (2017), e etelletsoeng ke Fraunhofer Institute for Production and Systems Reliability (LBF) Jeremane, e rerileng ho hlahisa likaroloana tsa mabili a ka pele bakeng sa lifofane tse entsoeng ka carbon fiber tse matlafalitsoeng bakeng sa Airbus A320, Sepheo ke ho fokotsa boima ba 'mele ka 40%. Morero o tšehelitsoe ka chelete e ka bang EUR 200,000.

2.4 Korea

Korea Boroa ea k'habone faeba R & amp; D le Industrialization qala morao, R & amp; D e qalile ka 2006, 2013 e ile ea qala ho kena sethaleng se sebetsang, ho fetola carbon fiber ea Korean tsohle tse itšetlehileng ka thepa e tsoang linaheng tse ling. Ho sehlopha sa lehae sa xiaoxing sa Korea Boroa le Khoebo ea Taiguang e le moemeli oa bo-pula-maliboho ba indasteri ba neng ba ikakhetse ka setotsoana tšimong ea moralo oa indasteri ea carbon fiber, tsoelo-pele e matla e matla. Ntle le moo, setsi sa tlhahiso ea carbon fiber se thehiloeng ke Toray Japan Korea le sona se kentse letsoho 'marakeng oa carbon fiber Korea ka boeona.

Mmuso oa Korea o khethile ho etsa xiaoxing Group A sebaka sa ho bokana bakeng sa liindasteri tse ncha tsa carbon fiber. Sepheo ke ho theha sehlopha sa indasteri ea carbon faeba, ho khothaletsa nts'etsopele ea tikoloho ea moruo tikolohong eohle e ka Leboea, sepheo sa mantlha ke ho theha thepa ea carbon faeba → likarolo → sehlahiswa se feliloeng ketane ea tlhahiso e le 'ngoe, ho thehoa ha sehlopha sa carbon fiber incubation ho ka bapisoa le Silicon Valley United States, ho tlanya limmaraka tse ncha, ho theha boleng bo bocha, Fihlella sepheo sa lihlahisoa tse rekisoang ka $10. 55.2 li-yuan tse limilione tse likete) ka 2020.

3. tlhahlobo ea lipatlisiso tsa lefats'e tsa carbon fiber le tlhahiso ea lipatlisiso

Karolwana ena e bala dipampiri tsa SCI tse amanang le dipatlisiso tsa carbon faeba le diphetho tsa patent tsa DII ho tloha ka 2010, e le ho sekaseka dipatlisiso tsa thuto le dipatlisiso tsa indasteri le ntshetsopele ya thekenoloji ya lefatshe la carbon faeba ka nako e le nngwe, le ho utlwisisa ka botlalo kgatelopele ya dipatlisiso le ntshetsopele ya carbon faeba matjhabeng.

Lintlha tse nkiloeng polokelong ea Scie le polokelong ea boitsebiso ea Dewent tepong ea polokelo ea mahlale e hatisitsoeng ke Clarivate Analytics; nako ea ho khutlisa nako: 2010-2017; letsatsi la ho khutlisa: Hlakola 1, 2018.

Leano la ho Fumana Pampiri ea SCI: Ts=((carbonfibre* kapa Carbonfiber*) kapa ("Carbon fiber*" not"carbon Fiberglass") kapa "carbon fiber*" kapa "carbonfilament*" kapa ((polyacrylonitrile or pitch) le "precursor*" andfiber*) kapa ("graphite fiber*")) eseng () carbon) "bambo".

Dewent Patent Search Strategy: Ti=((carbonfibre* or Carbonfiber*) kapa ("Carbon fiber*" not"carbon Fiberglass") kapa "carbon fiber*" kapa "carbonfilament*" kapa ((polyacrylonitrile or pitch) le "precursor*" andfiber*) kapa ("graphite fiber*")) eseng ()) kapa carbon*(carbon) kapa carbon*( carbon) kapa fibre=( carbon fibre=( TS) kapa fibre=( TS) ("Carbon fiber*" eseng"carbon Fiberglass") kapa "carbon fibre*" kapa "carbonfilament*" kapa ((polyacrylonitrile kapa pitch) le "precursor*" andfiber*) kapa ("graphite fiber*")) eseng ("bamboo carbon")) leIP=(D01F-009/12 kapa D01F309 kapa D01F307 kapa D01F3000 kapa D01F30000 kapa D01F3000). D01F-009/14 kapa D01F-009/145or D01F-009/15 kapa D01F-009/155 kapa D01F-009/16 kapa D01F-009/17 kapa D01F-009/18 kapaD01F-009/20 kapa D009/20 D01F-009/22 kapa D01F-009/24 kapa D01F-009/26 kapaD01F-09/28 kapa D01F-009/30 kapa D01F-009/32 kapa C08K-007/02 kapa C08J-005/26 kapa D01F-09/28 kapa D01F-009/30 kapa D01F-009/32 kapa C08K-007/02 kapa C08J-005/005/04-04/04/04 D3C04/04/06 D3C04/06 kapa D06M-101/40 kapa D21H-013/50 kapa H01H-001/027 kapaH01R-039/24).

3.1 mokhoa

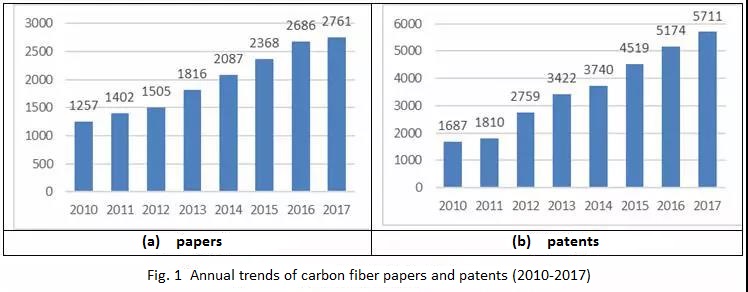

Ho tloha ka 2010, lipampiri tse amehang tse 16,553 li phatlalalitsoe lefatšeng ka bophara, 'me litokelo tsa boqapi tse 26390 li sebelisitsoe, kaofela li bonts'a mokhoa o tsitsitseng oa ho nyoloha selemo le selemo (setšoantšo sa 1).

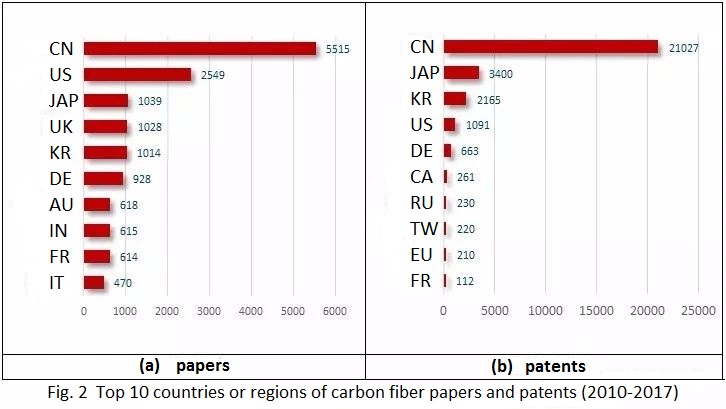

3.2 Kabo ea naha kapa sebaka

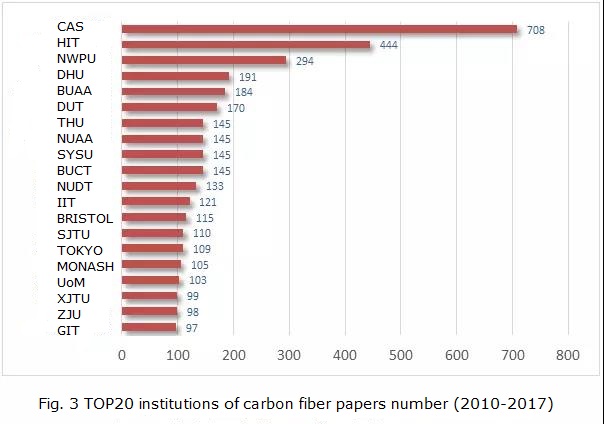

Litsi tse 10 tse phahameng ka ho fetisisa tse nang le tlhahiso e kholo ka ho fetisisa ea pampiri ea lefats'e ea lipatlisiso tsa carbon fiber li tsoa Chaena, tseo tse 5 tsa tsona tse holimo e leng: Chinese Academy of Sciences, Harbin Institute of Technology, Northwestern University of Technology, Univesithi ea Donghua, Beijing Institute of Aeronautics and Astronautics. Har'a mekhatlo e tsoang linaheng tse ling, Mokhatlo oa Indian of Technology, Univesithi ea Tokyo, Univesithi ea Bristol, Univesithi ea Monash, Univesithi ea Manchester le Georgia Institute of Technology Rank pakeng tsa 10 ~ 20 (sa feiga. 3).

Palo ea likopo tsa patent litsing tse 30 tse holimo, Japane e na le 5, 'me 3 ea tsona e maemong a mahlano, khamphani ea Toray e behiloe pele, e lateloa ke Mitsubishi Liyang (ea bobeli), Teijin (4th), East State (10), Japan Toyo Textile Company (la bo24), China e na le litsi tse 21, Sinopec Group e na le palo e kholo ka ho fetisisa ea litokelo tsa molao, khamphani ea bobeli ea Kebin, Harnan ea boraro, ea boraro ea khamphani ea Theknoloji. Univesithi ea Donghua, China Shanghai Petrochemical, Beijing Chemical Industry, joalo-joalo, Chinese Academy of Sciences Shanxi Coal kopo e qapiloeng Patent 66, e boemong ba bo27, mekhatlo ea Korea Boroa e na le 2, eo Xiaoxing Co., Ltd. e leng ea pele, e boemong ba borobeli.

Litsi tsa tlhahiso, tlhahiso ea pampiri haholo-holo ho tloha liunivesithing le litsi tsa lipatlisiso tsa saense, tlhahiso ea patent haholo-holo ho tloha k'hamphani, ho ka bonoa hore tlhahiso ea carbon faeba ke indasteri ea theknoloji e phahameng, e le 'mele o ka sehloohong oa carbon fiber R & amp; d Development Industry, khampani khomaretse bohlokoa haholo ho tshireletso ya carbon faeba R & amp; d thekenoloji, haholo-holo lik'hamphani tse 2 tse kholo tsa Japane, Palo ea litokelo tsa molao e sa le pele haholo.

3.4 Libaka tsa Patlisiso tse Hotspots

Lipampiri tsa lipatlisiso tsa carbon fiber li bua ka lihlooho tse ngata tsa lipatlisiso: li-composites tsa carbon fiber (ho kenyeletsoa li-composites tse matlafalitsoeng ka carbon fiber, metsoako ea polymer matrix, joalo-joalo), lipatlisiso tsa thepa ea mochine, tlhahlobo ea lintho tse fokolang, carbon nanotubes, delamination, matlafatso, mokhathala, microstructure, electrostatic spinning, phekolo ea holim'a metsi, adsorp. Lipampiri tse sebetsanang le mantsoe ana a bohlokoa li etsa 38.8% ea palo eohle ea lipampiri.

Litokelo tsa ho qaptjoa ha carbon fiber li akaretsa lihlooho tse ngata tse amanang le ho lokisoa ha carbon fiber, lisebelisoa tsa tlhahiso le lisebelisoa tse kopantsoeng. Har'a bona, Japane Toray, Mitsubishi Liyang, Teijin le lik'hamphani tse ling tse "carbon faeba matlafatsoa polymer metsoako" tšimong ea moralo bohlokoa botekgeniki, ho phaella moo, Toray le Mitsubishi Liyang ka "Polyacrylonitrile tlhahiso ea carbon faeba le thepa ea tlhahiso", "ka nitrile unsaturated, tse kang polyacrylonitrile, polydevinylidene fiber le tlhahiso ea carbonethylecyne tse ling" na le tlhahiso ea carbonethylene le carbonethylene tse ling. karolo e kholo ea moralo oa patent, le k'hamphani ea Japane ea Teijin "khaboneng fiber le metsoako ea oksijene e kopantsoeng" e na le karolo e kholoanyane ea moralo oa patent.

China Sinopec Group, Beijing Chemical University, Chinese Academy of Sciences Ningbo Materials ka "polyacrylonitrile tlhahiso ea carbon fiber le thepa ea tlhahiso" e na le karolo e kholo ea sebopeho sa patent; Ho phaella moo, Beijing University of Chemical Engineering, Chinese Academy of Sciences Shanxi Coal Chemical Institute le Chinese Academy of Sciences Ningbo materials key Layout "Sebelisa inorganic element faeba e le metsoako ea polymer motsoako ho lokisetsa" thekenoloji e na le Harbin Institute of Technology e tsepamisitse maikutlo holim'a moralo oa "phekolo ea carbon faeba", "carbon faeba le metsoako e nang le oksijene" le mahlale a mang.

Ho phaella moo, ho fumanoa lipalo-palo tsa selemo le selemo tsa kabo ea lipalo-palo tsa litokelo tsa lefats'e hore libaka tse ngata tse chesang tse chesang li qalile ho hlaha lilemong tse tharo tse fetileng, tse kang: "Liqapi tsa polyamides tse fumanoeng ho thehoa ha carboxylate bonding reaction ka ketane e kholo", "liqapi tsa polyester ho tloha ho thehoa ha 1 carboxylic acid ester bonds", syntheic chain chain asiti ea carboxylic e nang le metsoako ea oksijene e le metsoako ea metsoako ea carbon faeba ", "ka mokhoa oa mahlakore a mararo a ho tiisa kapa ho phekoloa ha thepa ea masela", "ether ea unsaturated, acetal, semi-acetal, ketone kapa aldehyde ka feela carbon-carbon unsaturated bond reaction to the production of polymer Compounds", "adiabatic material pipe kapa sosters" phala ea adiabatic e nang le fiber phosphate.

Lilemong tsa morao tjena, R & amp; d lefapheng la carbon fiber e hlahile, 'me boholo ba katleho e tsoa United States le Japane Theknoloji ea morao-rao ea morao-rao ha e tsepamise maikutlo feela ho tlhahiso ea carbon fiber le theknoloji ea ho lokisa, empa hape le ho sebelisoa ka mefuta e mengata ea thepa ea likoloi, tse kang tse bobebe, khatiso ea 3D, le lisebelisoa tsa tlhahiso ea matla. Ntle le moo, ho ntlafala le ho sebelisoa ha thepa ea carbon fiber, ho lokisoa ha lehong la lignin carbon fiber le likatleho tse ling li na le ts'ebetso e khanyang ea mahlo. Liphetho tsa moemeli li hlalositsoe ka tlase:

1) Setsi sa Theknoloji sa US Georgia se phunyeletsa theknoloji ea carbon fiber ea moloko oa boraro

Ka Phupu 2015, ka lithuso tsa lichelete tsa DARPA, Setsi sa Theknoloji sa Georgia, se nang le mokhoa o mocha oa ho ohla li-pan-based carbon fiber gel, se ile sa eketsa haholo modulus ea eona, ho feta Hershey IM7 Carbon fiber, eo hona joale e sebelisoang haholo lifofaneng tsa sesole, e tšoaeang naha ea bobeli lefats'eng ho tseba moloko oa boraro oa theknoloji ea carbon fiber ka mor'a Japane.

Matla a thata a gel e ohlang carbon fiber e entsoeng ke Kumarz e fihla ho 5.5 ho isa ho 5.8Gpa, 'me modulus e tsitsitseng e pakeng tsa 354-375gpa. "Ena ke fiber e tsoelang pele e tlalehiloeng ka matla a phahameng ka ho fetisisa le modulus ea ts'ebetso e felletseng. Ka har'a sephutheloana se sekhutšoane sa filament, matla a tensile ho fihla ho 12.1Gpa, e tšoanang ke polyacrylonitrile carbon fiber e phahameng ka ho fetisisa."

2) Theknoloji ea ho futhumatsa maqhubu a motlakase

Ka 2014, Nedo e ile ea theha theknoloji ea ho futhumatsa maqhubu a motlakase. Theknoloji ea electromagnetic wave carbonization e bua ka tšebeliso ea theknoloji ea ho futhumatsa maqhubu a motlakase ho etsa carbonization ea fiber khatellong ea sepakapaka. Ts'ebetso ea carbon fiber ha e le hantle e tšoana le carbon fiber e hlahisoang ke mocheso o phahameng oa mocheso, modulus elastic e ka fihla ho feta 240GPA, 'me elongation nakong ea khefu e feta 1.5%, e leng katleho ea pele lefatšeng.

Lintho tse kang fiber li entsoe ka carbonized by electromagnetic wave, e le hore lisebelisoa tsa sebōpi sa carbonization tse sebelisetsoang ho futhumatsa mocheso o phahameng ha li hlokehe. Ts'ebetso ena ha e fokotse feela nako e hlokahalang bakeng sa carbonization, empa hape e fokotsa tšebeliso ea matla le ho fokotsa tlhahiso ea CO2.

3) taolo e ntle ea ts'ebetso ea carbonization

Ka Hlakubele 2014, Toray e phatlalalitse nts'etsopele e atlehileng ea t1100g carbon fiber. Toray e sebelisa mokhoa o tloaelehileng oa ho phunya theknoloji ho laola mokhoa oa carbonization, ho ntlafatsa microstructure ea carbon fiber ho nanoscale, ho laola graphite microcrystalline orientation, boholo ba microcrystalline, litšitiso joalo-joalo ka fiber ka mor'a carbonization, e le hore matla le modulus rekere li ka ntlafatsoa haholo. Matla a matla a t1100g ke 6.6GPa, e leng 12% e phahameng ho feta ea T800, 'me modulus elastic ke 324GPa' me e eketsehile ka 10%, e kenang sethaleng sa indasteri.

4) Theknoloji ea Phekolo ea Bokaholimo

Teijin East State e atlehile ho hlahisa theknoloji ea phekolo ea plasma holim'a metsi e ka laolang ponahalo ea carbon fiber ka metsotsoana e seng mekae feela. Theknoloji ena e ncha e nolofatsa haholo ts'ebetso eohle ea tlhahiso mme e fokotsa tšebeliso ea matla ka 50% ha e bapisoa le theknoloji e teng ea kalafo ea holim'a metsi bakeng sa tharollo ea metsi a electrolyte. Ho feta moo, ka mor'a phekolo ea plasma, ho ile ha fumanoa hore ho khomarela matrix a fiber le resin ho boetse ho ntlafatsoa.

5) ho ithuta ka sekhahla sa ho boloka matla a carbon fiber tensile tikolohong e phahameng ea mocheso oa graphite

Lisebelisoa tsa Ningbo li atlehile ho etsa lipatlisiso tse qaqileng mabapi le tlhahlobo ea ts'ebetso, lipatlisiso tsa sebopeho le ts'ebetso ea ts'ebetso ea matla a phahameng a malapeng le mokhoa o molelele oa carbon fiber, haholo-holo mosebetsi oa ho etsa lipatlisiso mabapi le lebelo la ho boloka carbon fiber tensile matla sebakeng se phahameng sa mocheso oa graphite, le tokiso ea morao-rao e atlehileng ea matla a phahameng le modulus carbon fiber e nang le matla a thata 5.24GPa le tensile modulus volume 593GPa e tsoela pele ho ba le monyetla oa ho ba le matla a matla a 593GPa ho feta Japane. m60j matla a phahameng a entsoeng ka carbon fiber (matla a tensile 3.92GPa, tensile modulus 588GPa).

6) Microwave Graphite

Yongda Advanced Materials e atlehile ho nts'etsapele thekenoloji e ikhethileng ea United States ea "ultra-high heat graphite", tlhahiso ea carbon fiber e mahareng le e phahameng, e atlehile ho phunyeletsa litšitiso tse tharo ho nts'etsopele ea carbon fiber e phahameng, thepa ea graphite e theko e boima ebile e tlas'a taolo ea machaba, mathata a theknoloji ea silika e tala, tlhahiso ea lihlahisoa tse tlaase le tse phahameng. Ho fihlela hajoale, Yongda e hlahisitse mefuta e 3 ea likhoele tsa khabone, tseo kaofela li phahamisitseng matla le modulus ea fiber ea khabone ea pele e neng e batla e le tlase ho fihla bophahamong bo bocha.

7) Ts'ebetso e ncha ea ho qhibiliha ha terata e tala ea carbon fiber e entsoeng ka pan-based ka Fraunhofer, Jeremane.

Fraunhofer Institute of Applied Polymers (Applied polymer Research, IAP) e sa tsoa phatlalatsa hore e tla bontša theknoloji ea morao-rao ea Comcarbon ho Berlin Air Show Ila ka April 2018 25, 29th. Theknoloji ena e fokotsa haholo litšenyehelo tsa tlhahiso ea carbon fiber e hlahisoang ka bongata.

Setšoantšo sa 4 Ho ohia ha terata e tala.

Hoa tsebahala hore lits'ebetsong tsa setso, halofo ea litšenyehelo tsa tlhahiso ea pan-based carbon fiber e sebelisoa nakong ea tlhahiso ea terata e tala. Ka lebaka la ho se khonehe ha terata e tala ho qhibiliha, e tlameha ho hlahisoa ka mokhoa o bitsang chelete e ngata oa tharollo ea tharollo (Solution Spinning). "Ho fihlela sena, re thehile mokhoa o mocha oa tlhahiso ea silika e tala e entsoeng ka pan, e ka fokotsang litšenyehelo tsa tlhahiso ea terata e tala ka 60%. Ena ke mokhoa oa ho ohla oa moruo le o ka khonehang, o sebelisa "copolymer" e entsoeng ka ho khetheha e entsoeng ka pan-based. "Dr. Johannes Ganster, Letona la Biological Polymers Setsing sa Fraunhofer IAP, o hlalositse.

8) Theknoloji ea oxidation ea plasma

4M Carbon fiber e phatlalalitse hore e tla sebelisa thekenoloji ea plasma oxidation ho etsa le ho rekisa boleng bo holimo, bo theko e tlase fiber fiber e le sepheo sa maano, eseng feela ho fana ka tumello ea theknoloji. 4M e bolela hore theknoloji ea plasma oxidation e lebelo ka makhetlo a 3 ho feta theknoloji e tloaelehileng ea oxidation, athe tšebeliso ea matla e ka tlaase ho karolo ea boraro ea theknoloji ea setso. 'Me lipolelo li tiisitsoe ke bahlahisi ba bangata ba machaba ba carbon fiber, ba buisanang le bahlahisi ba bangata ba lefats'e ba k'habone fiber le baetsi ba likoloi ho nka karolo e le ba qalang ba tlhahiso ea carbon fiber fibers e theko e tlaase.

9) Cellulose Nano fiber

Univesithi ea Kyoto ea Japane, hammoho le bafani ba likarolo tse 'maloa tse kholo tse kang k'hamphani ea ho kenya motlakase (mofani oa Toyota e kholo ka ho fetisisa) le Daikyonishikawa Corp., e sebetsa ho nts'etsopele ea lisebelisoa tsa polasetiki tse kopanyang li-cellulose nanofibers, Boitsebiso bona bo entsoe ka ho pshatla makhasi a lehong ka microns tse seng kae (1 ka limilimithara tse sekete). Boima ba thepa e ncha ke karolo ea bohlano feela ea boima ba tšepe, empa matla a eona a makhetlo a mahlano a tšepe.

10) 'mele oa pele oa carbon fiber oa polyolefin le lignin lihlahisoa tse tala

Oak Ridge National Laboratory e United States esale e sebetsa liphuputsong tsa carbon fiber tse theko e tlaase ho tloha ka 2007, 'me ba thehile 'mele oa carbon fiber front for polyolefin le lignin raw, hammoho le theknoloji e tsoetseng pele ea plasma pre-oxidation le microwave carbonization.

11) Polima e ncha (polymer precursor) e ile ea ntlafatsoa ka ho tlosa kalafo ea refractory

Mokhoeng oa tlhahiso o etelletsoeng pele ke Univesithi ea Tokyo, ho entsoe polima e ncha (polymer precursor) ho tlosa kalafo e hanyetsanang. Taba ea bohlokoa ke hore ka mor'a ho ohla polymer ka silika, ha e etse phekolo ea pele ea ho hanyetsa, empa e etsa hore e be oxidize ka har'a solvent. Sesebediswa sa ho futhumatsa ka microwave se futhumatswa ho feta 1000 ℃ bakeng sa carbonization. Nako ea ho futhumatsa e nka metsotso e 2-3 feela. Ka mor'a phekolo ea carbonization, plasma e boetse e sebelisoa ho etsa phekolo ea holim'a metsi, e le hore carbon fiber e ka etsoa. Kalafo ea plasma e nka nako e ka tlase ho metsotso e 2. Ka tsela ena, nako ea pele ea sintering ea metsotso e 30-60 e ka fokotsoa hore e be metsotso e ka bang 5. Mokhoeng o mocha oa tlhahiso, phekolo ea plasma e etsoa ho ntlafatsa maqhama pakeng tsa carbon fiber le thermoplastic resin e le lisebelisoa tsa motheo tsa CFRP. The tensile elastic modulus ea carbon fiber e entsoeng ka mokhoa o mocha oa tlhahiso ke 240GPa, matla a ho tiea ke 3.5GPa 'me bolelele bo fihla ho 1.5%. Maemo ana a lekana le a Toray Universal grade carbon fiber T300 e sebelisoang bakeng sa thepa ea lipapali, joalo-joalo.

12) ho tsosolosa le ho sebelisoa ha lisebelisoa tsa carbon fiber ho sebelisa mokhoa oa bethe o nang le metsi

Mengran Meng, sengoli sa pele sa thuto, o itse: "Ho tsosolosoa ha carbon fiber ho fokotsa tšusumetso tikolohong ha ho bapisoa le tlhahiso ea carbon fiber e tala, empa ho na le tlhokomeliso e fokolang ea mekhoa e ka 'nang ea e-ba teng ea ho tsosolosa le bokhoni ba moruo ba ho tsosolosa tšebeliso ea carbon fiber." ditsamaiso. Mekhoa ena e tlosa karolo ea polasetiki ea thepa e entsoeng ka motsoako, e siea carbon fiber, e ka fetoloang ho ba likhoele tse tangled fiber ho sebelisa theknoloji ea ho etsa pampiri e metsi, kapa ho hlophisoa bocha hore e be likhoele tse tataisoang.

Bafuputsi ba ile ba lekanya hore carbon fiber e ka fumanoa litšila tse entsoeng ka carbon fiber ho sebelisa mokhoa oa bethe o nang le metsi, o hlokang 5 feela ea lidolara / kg le ka tlase ho 10% ea matla a hlokahalang ho etsa fiber e ka sehloohong ea carbon. Li-fiber tsa carbon tse tsosolositsoeng tse hlahisoang ke mekhoa ea bethe ea metsi ha li fokotse modulus, 'me matla a ho tsitsa a fokotsehile ka 18% ho ea ho 50% ha a bapisoa le li-fiber tsa carbon, e leng se etsang hore e tšoanelehe bakeng sa lisebelisoa tse hlokang ho tiea ho hoholo ho e-na le matla. "Li-fiber tsa carbon tse tsosolositsoeng li ka 'na tsa e-ba tse loketseng bakeng sa likopo tse se nang sebopeho tse hlokang boima bo bobebe, tse kang liindasteri tsa likoloi, tsa kaho, tsa moea le tsa lipapali," ho boletse Meng.

13) Theknoloji e ncha ea ho sebelisa carbon fiber e entsoeng United States

Ka June 2016, bafuputsi ba Setsi sa Theknoloji sa Georgia sa United States ba ile ba kolobisa carbon fiber ka har'a motsoako o nang le joala ho qhibilihisa resin ea epoxy, likhoele tse arohaneng le li-epoxy resin li ka sebelisoa hape, katleho ea katleho ea ho hlaphoheloa ha carbon fiber.

July 2017, Univesithi ea Washington State e boetse e ntlafalitse thekenoloji ea ho hlaphoheloa ha carbon faeba, e sebelisa acid e fokolang e le sesebelisoa, tšebeliso ea ethanol ea metsi ka mocheso o batlang o le tlaase ho senya thepa ea thermosetting, e bolileng ea carbon fiber le resin e bolokiloe ka thoko, 'me e ka kenngoa ho ikatisa.

14) Nts'etsopele ea theknoloji ea 3D ea khatiso ea carbon fiber enke ka laboratoring ea LLNL, USA

Ka Hlakubele 2017, Lawrence Livemore National Laboratory (LLNL) e United States e ile ea qapa lisebelisoa tsa pele tsa 3D tse hatisitsoeng tse sebetsang hantle haholo, tsa boemo ba lifofane tsa khabone. Ba sebelisitse mokhoa oa khatiso oa 3D oa ho fetisetsa enke ka kotloloho (DIW) ho theha meaho e rarahaneng ea mahlakore a mararo e ntlafalitseng haholo lebelo la ts'ebetso bakeng sa ho sebelisoa litlholisanong tsa likoloi, tsa sefofane, tsa ts'ireletso le lithuthuthu le ho surfing.

15) United States, Korea le Chaena li sebelisana ho nts'etsopele ea carbon fiber bakeng sa ho hlahisa matla

Ka Phato 2017, khamphase ea Dallas ea Univesithi ea Texas, Univesithi ea Hanyang Korea, Univesithi ea Nankai e Chaena le litsi tse ling li ile tsa sebelisana ho nts'etsopele ea lisebelisoa tsa khoele ea carbon fiber bakeng sa ho hlahisa matla. Khoele e qala ho kolobisoa ka tharollo ea electrolyte e kang brine, e lumellang li-ion tse ka har'a electrolyte hore li khomarele holim'a carbon nanotubes, e ka fetoloang matla a motlakase ha khoele e tiisitsoe kapa e otlolohile. Lisebelisoa li ka sebelisoa sebakeng leha e le sefe se nang le matla a kinetic a tšepahalang 'me se loketse ho fana ka matla ho li-sensor tsa IoT.

16) Khatelo-pele e ncha lipatlisisong tsa lehong la lignin carbon fiber tse fumanoeng ke Machaena le Amerika ka ho latellana

Ka March 2017, sehlopha se khethehileng sa fiber sa Ningbo Institute of Materials Technology le boenjiniere se ile sa lokisa lignin-acrylonitrile copolymer e nang le spinnability e ntle le botsitso ba mocheso ka ho sebelisa esterification le mahala radical copolymerization theknoloji ea mehato e 'meli ea phetoho. Li-filaments tse tsoelang pele tsa boleng bo phahameng li ile tsa fumanoa ka ho sebelisa mokhoa oa ho pota-pota oa copolymer le metsi, 'me compact carbon fiber e ile ea amoheloa ka mor'a ho tsitsisa mocheso le phekolo ea carbonization.

Ka Phato 2017, sehlopha sa bafuputsi sa Birgitte ahring Univesithing ea Washington e United States se ile sa kopanya lignin le polyacrylonitrile ka likarolo tse fapaneng, sa ntan'o sebelisa theknoloji ea ho qhibilihisa e qhibilihisang ho fetolela lipolymer tse tsoakiloeng hore e be likhoele tsa khabone. Phuputso e fumane hore lignin e kenyelelitsoeng ho 20% ~ 30% ha ea ka ea ama matla a carbon fiber 'me e ne e lebeletsoe hore e sebelisoe ho hlahisa thepa ea theko e tlaase ea carbon fiber bakeng sa likarolo tsa likoloi kapa tsa lifofane.

Qetellong ea 2017, National Renewable Energy Laboratory (NREL) e ile ea lokolla lipatlisiso mabapi le ho etsoa ha acrylonitrile ho sebelisa litšila tsa limela, tse kang joang ba poone le joang ba koro. Ba qala ka ho qhaqha lisebelisoa tsa limela hore e be tsoekere ebe ba li fetola li-acids, ebe ba li kopanya le li-catalyst tse theko e tlaase ho hlahisa lihlahisoa tse lebisitsoeng.

17) Japane e hlahisa mochine oa pele oa carbon fiber o matlafalitsoeng ke thermoplastic composite car chassis

October 2017, thekenoloji e ncha ea indasteri ea matla ea Japane e kopantsoeng R & amp; d Setsi le Setsi sa Patlisiso sa Likopano tsa Naha sa Nagoya University se atlehile ho theha chassis ea koloi ea pele ea carbon fiber e matlafalitsoeng ke thermoplastic composite car. Ba sebelisa li-composite tsa othomathike tse telele tse matlafalitsoeng tsa thermoplastic ka kotloloho, ts'ebetso e tsoelang pele ea k'habone le likaroloana tsa resin ea thermoplastic, ho etsa metsoako e matlafalitsoeng ea fiber, ebe ka ho futhumatsa le ho qhibiliha, tlhahiso e atlehileng ea chassis ea koloi ea thermoplastic CFRP.

5. litlhahiso mabapi le R & D ea theknoloji ea carbon faeba Chaena

5.1 Sebopeho se shebileng pele, se shebaneng le sepheo, se tsepamisitse maikutlo ho phunyeletse molokong oa boraro oa theknoloji ea carbon fiber.

Theknoloji ea China ea moloko oa bobeli oa carbon fiber ha e e-s'o be le katleho e pharaletseng, naha ea rona e lokela ho leka ho shebana le maemo a tlang pele a tla kopanya litsi tsa rona tse amehang tsa lipatlisiso, a shebane le ho hapa mahlale a bohlokoa, sepheo sa moloko oa boraro oa lipatlisiso le nts'etsopele (ke hore e sebetsa ho matla a holimo a sefofane, modulus e phahameng, theknoloji ea carbon fiber composite le lisebelisoa tse ling tsa ho lokisa carbon fiber), le theknoloji e tsoetseng pele ea carbon fiber. bobebe, theko e tlase e kholo ea tow carbon faeba tokisetso, thekenoloji e eketsang tlhahiso ea carbon fiber composite material, thekenoloji ea ho tsosolosa le mahlale a potlakileng a prototyping.

5.2 Ho hokahanya mokhatlo, ho matlafatsa ts'ehetso, ho theha merero e meholo ea tekheniki ho tsoela pele ho tšehetsa lipatlisiso tse kopanetsoeng.

Hona joale, ho na le ditheo tse ngata ho etsa lipatlisiso carbon faeba Chaena, empa matla a qhalakantsoeng, 'me ha ho na momahaneng R & amp; d mokhoa oa mokhatlo le tšehetso e matla ea lichelete bakeng sa khokahanyo e sebetsang. Ho latela boiphihlelo ba nts'etsopele ea linaha tse tsoetseng pele, ho hlophisoa le ho hlophisoa ha merero e meholo ho phetha karolo e kholo ho nts'etsopele ea sebaka sena sa botekgeniki. Re lokela ho tsepamisa maikutlo ho China Molemo R & amp; d Matla, ka pono ea China ea k'habone faeba katleho e khōlō R & amp; d thekenoloji ho qala merero e meholo, ho matlafatsa ts'ebetso ea ts'ebelisano ea thekenoloji, le ho khothaletsa kamehla boemo ba theknoloji ea China ea ho etsa lipatlisiso ka faeba ea carbon, tlhōlisano ea carbon fiber le motsoako oa machaba.

5.3 Ho ntlafatsa mokhoa oa tlhahlobo oa ts'ebetso ea ts'ebetso ea katleho ea tekheniki

Ho ea ka pono ea tlhahlobo ea moruo ea lipampiri tsa SCI, China ea carbon fiber e le lisebelisoa tse phahameng tsa ts'ebetso tse sebelisoang likarolong tse sa tšoaneng tsa lipatlisiso, empa bakeng sa tlhahiso ea carbon fiber le theknoloji ea ho lokisetsa, haholo-holo ho lebisa tlhokomelo ho fokotsa litšenyehelo, ho ntlafatsa katleho ea tlhahiso ea lipatlisiso tse fokolang. Ts'ebetso ea tlhahiso ea carbon fiber e telele, lintlha tsa bohlokoa tsa theknoloji, litšitiso tse phahameng tsa tlhahiso, ke ho kopanya mekhoa e mengata, ho kopanngoa ha mahlale a mangata, ho hloka ho phunyeletsa litšitiso tsa tekheniki, ho khothaletsa ka katleho "litšenyehelo tse tlase, ts'ebetso e phahameng" ea mantlha ea ho itokisa le nts'etsopele, ka lehlakoreng le leng, ho hlokahala ho matlafatsa matsete a lipatlisiso, ka lehlakoreng le leng, ho hloka ho fokolisa lefapha la lipatlisiso tsa mahlale, ho matlafatsa tlhahlobo ea ts'ebetso ea ts'ebetso ea ts'ebetso, ho matlafatsa ts'ebetso ea ts'ebetso ea ts'ebetso, ho matlafatsa ts'ebetso ea ts'ebetso ea ts'ebetso. tlhahlobo ea "quantitative", e lebisang tlhokomelo ho phatlalatso ea pampiri, ho hlahloba "boleng" ba boleng ba liphello.

5.4 Ho matlafatsa temoho ea litalenta tse kopaneng tsa theknoloji e tsoetseng pele

The tšobotsi e phahameng theknoloji ea carbon faeba thekenoloji etsa qeto ea bohlokoa ba litalenta tse khethehileng, hore na ba na le ho itšeha-matla konokono basebetsi botekgeniki ka ho toba etsa qeto ea boemo ba R & amp; D ea setsi.

Ka lebaka la thekenoloji ea carbon fiber R & D links, re lokela ho ela hloko koetliso ea basebetsi ba lik'hemik'hale, e le ho netefatsa khokahanyo le nts'etsopele ea lihokelo tsohle. Ho phaella moo, ho tloha historing ea tsoelo-pele ea lipatlisiso tsa carbon fiber Chaena, ho phalla ha litsebi tsa motheo tsa theknoloji hangata ke ntho ea bohlokoa e amang R & amp; d boemo ba setsi sa lipatlisiso. Ho boloka ho lokisoa ha litsebi tsa mantlha le R & amp; d lihlopha tsa mekhoa ea tlhahiso, li-composite le lihlahisoa tse kholo li bohlokoa bakeng sa ntlafatso e tsoelang pele ea theknoloji.

Re lokela ho tsoela pele ho matlafatsa koetliso le tšebeliso ea basebetsi ba khethehileng ba theknoloji e phahameng tšimong ena, ho ntlafatsa leano la tekolo le kalafo bakeng sa Technology R & amp; d litalenta, matlafatsa ho lengoa ha litalenta bacha, ka mafolofolo tšehetsa tšebelisano 'moho le ananyang le tsoang linaheng tse ling e tsoetseng pele R & amp; d mekhatlo, le ho tsebahatsa ka matla litalenta tse tsoetseng pele tsa kantle ho naha, joalo-joalo Sena se tla bapala karolo e kholo ho khothaletseng nts'etsopele ea lipatlisiso tsa faeba ea khabone Chaena.

E qotsitsoe ho-

Tshekatsheko mabapi le ntshetsopele ya thekenoloji ya lefatshe la carbon fiber le lesedi la yona ho ya China. Tian Yajuan,Zhang Zhiqiang,Tao Cheng,Yang ming,Ba jin,Chen Yunwei.World Sci-Tech R & D.2018

Nako ea poso: Dec-04-2018