Carbon fiber inorganic polymer fiber inorganic sabon abu tare da carbon abun ciki sama da 95%, tare da low yawa, high ƙarfi, high zafin jiki juriya, sosai sinadaran kwanciyar hankali, anti-gajiya, lalacewa-resistant shafa da sauran kyau kwarai asali jiki da sinadaran Properties, kuma yana da high vibration attenuation, mai kyau conductive thermal watsin, electromagnetic garkuwa yi da low thermal fadada coefficient da sauran halaye. Wadannan kyawawan kaddarorin suna yin fiber carbon da ake amfani da su sosai a cikin sararin samaniya, zirga-zirgar jiragen kasa, masana'antar kera motoci, makamai da kayan aiki, injinan gini, ginin gine-gine, injiniyan ruwa, injiniyan mai, makamashin iska, kayan wasanni da sauran fannoni.

Bisa la'akari da bukatu na kasa da kasa na kayayyakin fiber carbon, kasar Sin ta jera ta a matsayin daya daga cikin muhimman fasahohin masana'antu masu tasowa wadanda suka mai da hankali kan tallafi. A cikin tsarin kimiyya da fasaha na "Sha biyu-biyar" na kasa, shirye-shirye da fasahar aikace-aikace na babban aikin fiber carbon fiber ɗaya ne daga cikin mahimman fasahohin masana'antu masu tasowa masu tasowa waɗanda jihar ke tallafawa. A watan Mayun 2015, majalisar gudanarwar kasar Sin ta fitar da sabon tsarin "Made in China 2025" a hukumance, a matsayin daya daga cikin muhimman fannonin karfafawa da bunkasuwa, ciki har da manyan kayan aikin da suka dace, hada-hadar ci-gaba shi ne babban abin da ake mayar da hankali kan ci gaba a fannin sabbin kayayyaki. A watan Oktoba na shekarar 2015, Ma'aikatar Masana'antu da Watsa Labarai a hukumance ta buga "Manufar Sinanci na 2025 mahimmin taswirar fasaha na yankunan fasaha", "fiber mai girma da abubuwan da ke tattare da shi" a matsayin muhimmin abu mai mahimmanci, manufar 2020 ita ce "na'urorin fiber carbon na cikin gida don saduwa da bukatun fasaha na manyan jiragen sama da sauran kayan aiki masu mahimmanci." Nuwamba 2016, da Jihar Council bayar da "Goma sha uku da biyar" na kasa Strategic kunno kai masana'antu Development shirin, a fili nuna don ƙarfafa sabon abu masana'antu upstream da downstream hadin gwiwa goyon baya, a cikin carbon fiber composites da sauran filayen da za a gudanar da wani hadin gwiwa aikace-aikace matukin jirgi zanga-zanga, gina haɗin gwiwa aikace-aikace dandamali. A cikin Janairu 2017, ma'aikatar masana'antu da raya kasa, NDRC, kimiyya da fasaha, da kuma ma'aikatar kudi tare da hadin gwiwa tsara da "Jagora ga ci gaban sabon kayan masana'antu", da kuma bayar da shawarar cewa kamar yadda na 2020, "a cikin carbon fiber composites, high quality-na musamman karfe, ci-gaba haske gami kayan da sauran filayen cimma fiye da 70 key sabon tsarin kayan aikin gina masana'antu matakin da aikace-aikace na goyon bayan kasar Sin sabon tsarin da kayan aiki, da kuma samar da fiye da 70 key sabon tsarin matches da aikace-aikace. masana'antu."

Saboda fiber fiber da abubuwan da ke tattare da shi suna taka muhimmiyar rawa wajen kare ƙasa da rayuwar jama'a, masana da yawa sun fi mayar da hankali kan haɓakawa da nazarin yanayin bincike. Dokta Zhou Hong ya yi nazari kan gudunmawar kimiyya da fasaha da masana kimiyyar Amurka suka bayar a farkon matakan bunkasa fasahar fiber carbon fiber mai inganci, kuma ya yi nazari tare da ba da rahoto kan manyan aikace-aikace guda 16 da ci gaban fasahar kere-kere na carbon fiber na baya-bayan nan, da fasahar kera, kadarori da aikace-aikacen fiber carbon polyacrylonitrile da kuma yadda yake ci gaban fasaha a halin yanzu, ya ba da shawarar cewa Dr. matsalolin da ke faruwa a cikin ci gaban carbon fiber a China. Bugu da kari, mutane da yawa sun gudanar da bincike a kan nazarin awoyi na takardu da haƙƙin mallaka a fagen fiber carbon da abubuwan da ke tattare da su. Misali, Ma Xianglin da sauransu daga mahangar nazarin halittu daga 1998-2017 carbon fiber patent rarraba da aikace-aikace na filin bincike; Yang Sisi da sauransu bisa tushen innography dandali na duniya carbon fiber masana'anta neman hažžožin mallaka da kuma kididdiga bayanai, daga shekara-shekara ci gaban ci gaban na hažžožin, hažžožin, The lamban kira fasaha hotspot da core ikon mallakar fasaha an yi nazari.

Daga hangen nesa na bincike na fiber carbon fiber da yanayin ci gaba, kasar Sin ta bincike kusan aiki tare da duniya, amma ci gaban da aka sannu a hankali, high-yi carbon fiber samar da sikelin da ingancin idan aka kwatanta da kasashen waje da gibi, akwai wani gaggawa bukatar gaggawa R & amp; d tsari, ci gaba da tsara dabaru, ƙwace damar ci gaban masana'antu na gaba. Don haka, wannan takarda ta fara bincikar tsarin ayyukan ƙasashe a fagen bincike na fiber carbon, don fahimtar shirin R & amp; d hanyoyi a cikin kasashe daban-daban, kuma na biyu, saboda asali bincike da aikace-aikace bincike na carbon fiber yana da matukar muhimmanci ga fasaha bincike da kuma ci gaban carbon fiber, sabili da haka, Muna gudanar da nazarin metrology daga sakamakon bincike na ilimi-SCI takardun da aikace-aikace bincike sakamakon-patents a lokaci guda don samun wani m fahimtar R & amp; d ci gaba a fagen carbon fiber, da kuma duba kwanan nan bincike ci gaban a cikin wannan filin zuwa Peep International Frontier R & amp; d ci gaba. A karshe, bisa sakamakon binciken da aka yi a baya, an gabatar da wasu shawarwari kan hanyar bincike da bunkasa a fannin sinadarin carbon fiber a kasar Sin.

2. Carbon fibertsarin aikin bincike namanyan kasashe/yankuna

Manyan kasashen da ke samar da fiber carbon sun hada da Japan, Amurka, Koriya ta Kudu, wasu kasashen Turai da Taiwan, China. Ƙasashen fasaha na ci gaba a farkon matakin haɓaka fasahar fiber carbon sun fahimci mahimmancin wannan abu, sun aiwatar da tsarin dabarun, suna haɓaka haɓakar abubuwan fiber carbon.

2.1 Japan

Japan ita ce ƙasa mafi haɓaka don fasahar fiber carbon. Kamfanoni 3 a cikin Toray, Bong da Mitsubishi Liyang a Japan suna lissafin kusan kashi 70% ~ 80% na kasuwar samar da fiber carbon na duniya. Duk da haka, kasar Japan tana ba da muhimmanci sosai wajen kiyaye karfinta a wannan fanni, musamman ma samar da fasahar kere-kere da makamashi da muhalli masu inganci, tare da goyon bayan dan Adam da kudi mai karfi, da kuma wasu manufofi na yau da kullun, ciki har da tsarin makamashi na asali, tsarin dabarun ci gaban tattalin arziki da yarjejeniyar Kyoto, sun sanya wannan aiki mai mahimmanci da ya kamata a ci gaba. Dangane da tushen makamashi na kasa da manufofin muhalli, Ma'aikatar Tattalin Arziki, masana'antu da kadarori na Japan sun gabatar da "Binciken fasahar ceton makamashi da shirin ci gaba". Taimakawa da manufofin da ke sama, masana'antar fiber carbon fiber na Japan sun sami damar daidaita dukkan bangarorin albarkatu yadda ya kamata tare da haɓaka maganin matsalolin gama gari a cikin masana'antar fiber carbon.

"Ci gaban fasaha kamar sababbin sababbin kayan tsarin" (2013-2022) wani aiki ne da aka aiwatar a karkashin "aikin bincike na ci gaba na gaba" a Japan don cimma mahimmancin ci gaban fasahar kayan aikin da ake bukata da kuma haɗuwa da kayan aiki daban-daban, tare da babban manufar rage nauyin nauyi (rabin nauyin mota) na hanyar sufuri. Kuma a karshe gane da m aikace-aikace. Bayan da ya karbi aikin bincike da ci gaba a cikin 2014, Hukumar Ci gaban Fasaha ta Masana'antu (NEDO) ta ɓullo da ayyuka da yawa a cikin abin da gabaɗayan manufofin aikin bincike na carbon Fiber "Innovative carbon fiber basic bincike da ci gaba" sune: don haɓaka sabbin abubuwan haɗin fiber na carbon fiber; don bayyana tsarin samar da tsarin carbonization; kuma don haɓakawa da daidaita hanyoyin tantance fiber carbon. Aikin, wanda Jami'ar Tokyo ke jagoranta tare da hadin gwiwar Cibiyar Fasahar Masana'antu (NEDO), Toray, Teijin, Dongyuan, da Mitsubishi Liyang, ya sami gagarumin ci gaba a cikin watan Janairun 2016 kuma wani babban ci gaba ne a fagen samar da fiber carbon fiber da ke cikin kwanon rufi biyo bayan ƙirƙirar "Yanayin Kondo" a Japan a cikin 1959.

2.2 Amurka

Hukumar binciken tsaro ta Amurka (DARPA) ta kaddamar da aikin Advanced Structural Fiber a shekarar 2006 da nufin hada karfi da karfe wajen gudanar da bincike na kimiyya a kasar don samar da filayen tsarin zamani na gaba dangane da filayen carbon. Tare da goyon bayan wannan aikin, ƙungiyar masu bincike na Cibiyar Fasaha ta Jojiya a Amurka ta karya fasahar shirye-shiryen danyen waya a cikin 2015, ta haɓaka modules ɗinta na roba da kashi 30%, wanda ke nuna cewa Amurka tana da ƙarfin haɓaka na ƙarni na uku na carbon fiber.

A cikin 2014, Ma'aikatar Makamashi ta Amurka (DOE) ta ba da sanarwar tallafin dala miliyan 11.3 don ayyukan guda biyu akan "tsarin matakai masu yawa don canza sukarin da ba za a iya ci ba zuwa acrylonitrile" da "bincike da haɓakawa na acrylonitrile da aka samu daga haɓakar al'adu, haɓaka haɓakar haɓakar haɓakawa da haɓaka haɓakar haɓakar haɓakar haɓakawa da haɓaka haɓakar al'adu. kayan aikin fiber carbon da za a sabunta su don samar da albarkatun da ba na abinci ba masu sabuntawa, kamar itacen biomass, da kuma shirin rage farashin samar da filayen carbon da za a sabunta su zuwa kasa da $5/lb nan da 2020.

A cikin Maris 2017, Ma'aikatar Makamashi ta Amurka ta sake ba da sanarwar dala miliyan 3.74 don ba da gudummawar "ƙaddamar da aikin carbon fiber mai rahusa R & amp; d aikin" wanda Cibiyar Yammacin Amurka ta Amurka (WRI) ke jagoranta, wanda ke mai da hankali kan haɓaka abubuwan fiber carbon mai rahusa mai rahusa dangane da albarkatun kamar kwal da biomass.

Yuli 2017, Ma'aikatar Makamashi ta Amurka ta ba da sanarwar bayar da tallafin dala miliyan 19.4 don tallafawa bincike da haɓaka motocin ci-gaba masu amfani da makamashi, miliyan 6.7 daga cikinsu ana amfani da su don ba da gudummawar shirye-shiryen filaye masu ƙarancin farashi ta hanyar amfani da kayan ƙididdigewa, gami da haɓaka hanyoyin ƙima da yawa don haɗaɗɗen fasahar kwamfuta don tantance sha'awar sabbin ƙwayoyin fiber na haɓaka haɓakar ƙwayoyin carbon. ka'idar, koyon inji da sauran kayan aikin ana amfani da su don haɓaka kayan aikin kwamfuta na zamani don haɓaka ingantaccen zaɓi na albarkatun fiber carbon mai ƙarancin farashi.

2.3 Turai

Masana'antar fiber carbon fiber ta Turai ta haɓaka a Japan da Amurka a cikin shekarun saba'in ko tamanin na karni na 20, amma saboda fasaha da jari, yawancin kamfanoni masu samar da fiber carbon guda ɗaya ba su kiyaye babban lokacin haɓakar fiber carbon fiber bayan shekaru 2000 kuma ya ɓace, Kamfanin Jamus SGL shine kawai kamfani a Turai da ke da babban kaso na kasuwar fiber carbon ta duniya.

A cikin Nuwamba 2011, Tarayyar Turai ta ƙaddamar da aikin Eucarbon, wanda ke da nufin haɓaka ƙarfin masana'antu na Turai a cikin fiber carbon da kayan da aka riga aka yi wa ciki don sararin samaniya. Aikin ya dau shekaru 4, tare da jimlar jarin Yuro miliyan 3.2, kuma a cikin watan Mayun 2017 ya samu nasarar kafa layin samar da fiber na musamman na Turai na farko don aikace-aikacen sararin samaniya kamar tauraron dan adam, wanda hakan ya baiwa Turai damar ficewa daga dogaro da shigo da kayayyaki da kuma tabbatar da amincin samar da kayan.

Tsarin EU na Bakwai yana shirin tallafawa "fiber carbon mai aiki a cikin shirye-shiryen sabon tsarin da aka riga aka tsara tare da ingantaccen aiki mai tsada da aiki" (FIBRALSPEC) aikin (2014-2017) a cikin Yuro miliyan 6.08. The 4-shekara aikin, jagorancin National Technical University of Athens, Girka, tare da sa hannu na multinational kamfanoni kamar Italiya, da United Kingdom da kuma Ukraine, an mayar da hankali a kan ƙirƙira da kuma inganta aiwatar da ci gaba da shirye-shiryen na polyacrylonitrile na tushen carbon zaruruwa don cimma gwaji samar da ci gaba da pan-tushen carbon zaruruwa. Aikin ya samu nasarar kammala haɓakawa da aikace-aikacen fiber carbon da haɓaka fasahar haɗin gwiwa daga albarkatun polymer mai sabuntawa (kamar supercapacitors, matsugunan gaggawa na gaggawa, da samfuri na injin lantarki na jujjuyawar rufin ƙarfe da samar da layin samar da nanofibers, da sauransu).

Yawan girma na sassan masana'antu, kamar kera motoci, wutar lantarki da ginin jirgi, suna buƙatar sassauƙa, ƙayyadaddun ayyuka masu girma, wanda babbar kasuwa ce ga masana'antar fiber carbon. EU ta kashe Yuro miliyan 5.968 don ƙaddamar da aikin Carboprec (2014-2017), maƙasudin maƙasudin wanda shine haɓaka ƙima mai ƙarancin farashi daga kayan sabuntawa waɗanda ke yaɗuwa a Turai da haɓaka samar da filaye masu inganci ta hanyar carbon nanotubes.

Shirin bincike na Tarayyar Turai Cleansky II ya ba da gudummawar wani aikin "Composite taya R & amp; d" (2017), wanda Cibiyar Fraunhofer don Production da Amincewa da Tsarin (LBF) ke jagoranta a Jamus, wanda ke shirin haɓaka abubuwan haɗin gwiwa na gaba don fiber fiber na ƙarfafa jirgin sama don Airbus A320, Manufar ita ce rage nauyi da 40% idan aka kwatanta da kayan ƙarfe na al'ada. Ana gudanar da aikin ne da kusan EUR 200,000.

2.4 Koriya ta Kudu

Koriya ta Kudu ta carbon fiber R & amp; D da Industrialization fara marigayi, R & amp; D ya fara ne a cikin 2006, 2013 ya fara shigar da aikace-aikacen a hukumance, yana jujjuya fiber fiber na Koriya duk ya dogara da shigo da yanayin. Zuwa ga rukunin xiaoxing na gida na Koriya ta Kudu da Kasuwancin Taiguang a matsayin wakilin majagaba na masana'antu masu himma a fagen shimfidar masana'antar fiber carbon, haɓaka haɓaka yana da ƙarfi. Bugu da kari, tushen samar da fiber carbon da Toray Japan ya kafa a Koriya shi ma ya ba da gudummawa ga kasuwar fiber carbon a Koriya da kanta.

Gwamnatin Koriya ta Kudu ta zaɓi yin taron ƙungiyar xiaoxing A don sabbin masana'antu na fiber carbon. Manufar ita ce ta samar da gungu na masana'antar fiber carbon fiber, haɓaka haɓakar haɓakar yanayin yanayin tattalin arziƙi a duk yankin Arewa, babban makasudin shine samar da kayan fiber carbon → sassa → gama samfurin sarkar samar da tasha guda ɗaya, kafa gungu na fiber carbon fiber incubation cluster za a iya daidaita shi da Silicon Valley a Amurka, matsa sabbin kasuwanni, ƙirƙirar sabon ƙarin ƙimar, Cimma maƙasudin samfuran fiber na kusan dala biliyan 10. Yuan biliyan 55.2) nan da shekarar 2020.

3. bincike na duniya carbon fiber bincike da bincike fitarwa

Wannan sashin yana ƙididdige takaddun SCI da ke da alaƙa da binciken fiber fiber carbon da sakamakon haƙƙin mallaka na DII tun daga 2010, don nazarin binciken ilimi da bincike na masana'antu da haɓaka fasahar fiber carbon fiber na duniya a lokaci guda, da cikakken fahimtar ci gaban binciken fiber carbon fiber da ci gaba a duniya.

Bayanan da aka samo daga Scie database da Dewent database a cikin yanar gizo na Kimiyyar Kimiyya da Clarivate Analytics ya buga; Tsawon lokacin dawowa: 2010-2017; kwanan wata: Fabrairu 1, 2018.

SCI Takarda Maido Da Dabarun: Ts=((carbonfibre* ko Carbonfiber* ko ("Carbon fiber*"ba"carbon Fiberglass") ko "carbon fibre*" ko "carbonfilament*" ko ((polyacrylonitrile ko farar) da "precursor*" da fiber*) ko ("carbon fiber*")

Dabarun Neman Haɓakawa: Ti=(((carbonfibre* ko Carbonfiber* ko ("Carbon fiber*"ba"carbon Fiberglass") ko "carbon fibre*" ko "carbonfilament*" ko ((polyacrylonitrile ko farar) da "precursor*" and fiber**) ko ("carbon fiber*"ba"carbon fiberglass") ba ("carbon fiber*") Carbonfiber* ko ("Carbon fiber*"ba"carbon Fiberglass") ko "carbon fiber*" ko "carbonfilament*" ko ((polyacrylonitrile ko farar) da "precursor*" da fiber*) ko ("fiber graphite *")) ba ("bamboo carbon") da IP=(D01F-009/120) D01F-009/133 ko D01F-009/14 ko D01F-009/145 ko D01F-009/15 ko D01F-009/155 ko D01F-009/16 ko D01F-009/17 ko D01F-009/18F D01F-009/21 ko D01F-009/22 ko D01F-009/24 ko D01F-009/26 ko D01F-09/28 ko D01F-009/30 ko D01F-009/32 ko C08K-007/02 ko C08K-007/02 ko C08-03 ko D06M-014/36 ko D06M-101/40 ko D21H-013/50 ko H01H-001/027 koH01R-039/24).

3.1 Trend

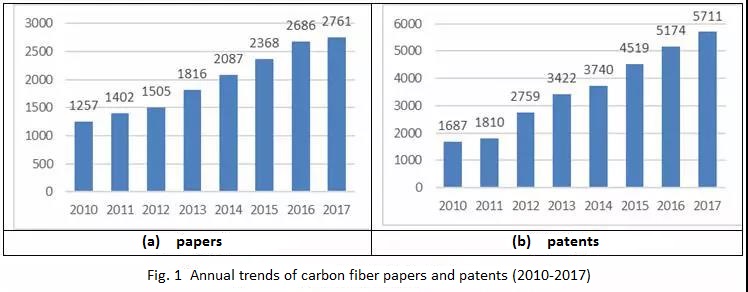

Tun daga 2010, an buga takardu 16,553 masu dacewa a duk duniya, kuma an yi amfani da haƙƙin ƙirƙira 26390, duk suna nuna ci gaba da haɓakawa kowace shekara (Hoto na 1).

3.2 Rarraba ƙasa ko yanki

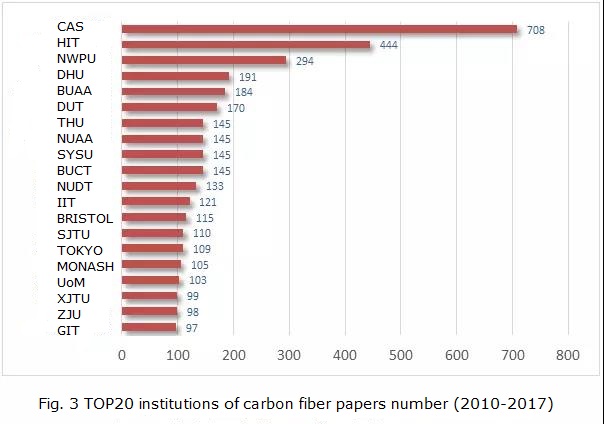

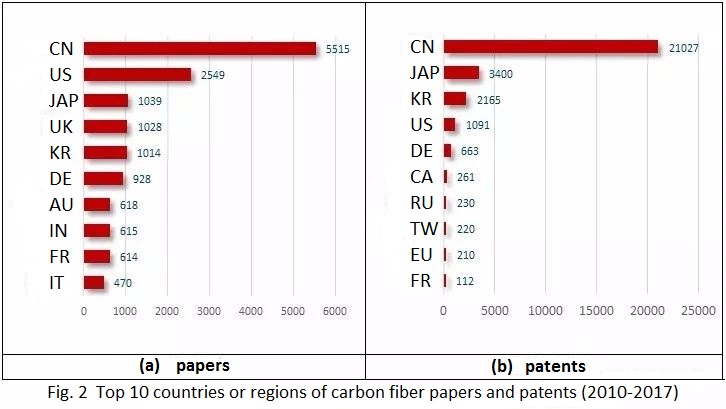

Manyan cibiyoyi 10 da suka fi fitar da mafi girma daga cikin takardar binciken fiber carbon fiber na duniya sun fito ne daga kasar Sin, daga cikinsu manyan 5 sun hada da: Kwalejin Kimiyya ta kasar Sin, Cibiyar Fasaha ta Harbin, Jami'ar Fasaha ta Arewa maso Yamma, Jami'ar Donghua, Cibiyar Nazarin Aeronautics ta Beijing da Sararin Samaniya. Daga cikin cibiyoyin kasashen waje, Cibiyar Fasaha ta Indiya, Jami'ar Tokyo, Jami'ar Bristol, Jami'ar Monash, Jami'ar Manchester da Cibiyar Fasaha ta Georgia tsakanin 10 ~ 20 (Fig. 3).

Yawan aikace-aikacen haƙƙin mallaka a cikin manyan cibiyoyin 30, Japan tana da 5, kuma 3 daga cikinsu suna cikin manyan biyar, Kamfanin Toray ya kasance na farko, sannan Mitsubishi Liyang (2nd), Teijin (4th), Gabas ta Tsakiya (10th), Japan Toyo Textile Company (24th), China yana da cibiyoyi 21, Sinopec Group yana da mafi girman adadin haƙƙin mallaka, Kamfanin Kamfanin Fasaha na Harbin Ketter, Cibiyar Fasaha ta uku, Cibiyar Fasaha ta Hebing Letter, na biyu Jami'ar, kasar Sin Shanghai Petrochemical, Beijing Chemical Industry, da dai sauransu, kasar Sin Academy of Sciences Shanxi Coal ƙirƙira Patent 66, ranked 27th, Koriya ta Kudu cibiyoyin da 2, wanda Xiaoxing Co., Ltd. ranked farko, ranking 8th.

Output cibiyoyin, da fitarwa na takarda yafi daga jami'o'i da kimiyya cibiyoyin bincike, lamban kira fitarwa yafi daga kamfanin, shi za a iya gani cewa carbon fiber masana'antu ne high-tech masana'antu, a matsayin babban jiki na carbon fiber R & amp; d Masana'antu Development, kamfanin dora muhimmanci sosai ga kariyar carbon fiber R & amp; d fasaha, musamman 2 manyan kamfanoni a Japan, Yawan haƙƙin mallaka ya riga ya wuce.

3.4 Wuraren Bincike

Takardun binciken fiber na carbon fiber sun rufe mafi yawan batutuwan bincike: Abubuwan haɗin fiber na carbon (ciki har da abubuwan haɗin fiber na carbon fiber, abubuwan haɗin gwiwar polymer matrix, da sauransu), bincike na kaddarorin injiniyoyi, ƙididdigar ƙayyadaddun ƙayyadaddun abubuwa, carbon nanotubes, delamination, ƙarfafawa, gajiya, microstructure, juyawa electrostatic, jiyya ta sama, adsorption da sauransu. Takardun da ke mu'amala da waɗannan kalmomin suna lissafin 38.8% na jimlar adadin takardu.

Halayen ƙirƙirar fiber na carbon sun ƙunshi mafi yawan batutuwan da suka shafi shirye-shiryen fiber carbon, kayan samarwa da kayan haɗin gwiwa. Daga cikin su, Japan Toray, Mitsubishi Liyang, Teijin da sauran kamfanoni a cikin "carbon fiber ƙarfafa polymer mahadi" a cikin filin da muhimmanci fasaha layout, a Bugu da kari, Toray da Mitsubishi Liyang a "Polyacrylonitrile samar da carbon fiber da samar da kayan aiki", "tare da unsaturated nitrile, kamar polyacrylonitrile, carbon polyvinylethylene samar da fasahohin da sauran fasahar fasaha. na tsarin haƙƙin mallaka, da kamfanin Teijin na Jafananci a cikin "fiber carbon da oxygen composites" suna da mafi girma rabo na tsarin haƙƙin mallaka.

China Sinopec Group, Beijing Chemical University, Sin Academy of Sciences Ningbo Materials a cikin "polyacrylonitrile samar da carbon fiber da kuma samar da kayan aiki" yana da wani babban rabo daga cikin patent layout; Bugu da kari, Jami'ar Beijing na Chemical Engineering, da kasar Sin Academy of Sciences Shanxi Coal Chemical Institute da Sin Academy of Sciences Ningbo kayan key Layout "Amfani da inorganic element fiber matsayin sinadaran polymer fili shirye-shirye" fasaha ya Harbin Cibiyar Technology mayar da hankali a kan layout na "carbon fiber magani", "carbon fiber da oxygen-dauke da fili composites" da sauran fasaha.

Bugu da kari, an samu daga shekara-shekara statistics rarraba statistics na duniya hažžožin cewa da dama sabon zafi spots sun fara fitowa a cikin shekaru uku da suka wuce, kamar: "Compositions na polyamides samu daga samuwar carboxylate bonding dauki a cikin babban sarkar", "polyester qagaggun daga samuwar 1 carboxylic acid ester bonds a cikin babban sarkar", "compositions na polyamides samu daga cikin samuwar carboxylate bonding dauki a cikin babban sarkar", "polyester abun da ke ciki daga samuwar 1 carboxylic acid ester bonds a cikin babban sarkar", "compositic acid". dauke da oxygen mahadi a matsayin sinadaran na carbon fiber composites", "a cikin uku-girma nau'i na solidification ko magani na yadi kayan", "unsaturated ether, acetal, Semi-acetal, ketone ko aldehyde ta hanyar kawai carbon-carbon unsaturated bond dauki ga samar da polymer Compounds", "adiabatic abu bututu ko na USB", "Carbon ether a kan sinadaran kamar yadda phosphate composites.

A cikin 'yan shekarun nan, R & amp; d a cikin sashin fiber carbon ya fito, tare da mafi yawan ci gaban da aka samu daga Amurka da Japan Sabbin fasahohin fasahar zamani ba wai kawai a kan samar da fiber carbon da fasahar shirye-shirye ba, har ma a kan aikace-aikacen da ke cikin kewayon kewayon kayan kera motoci, irin su nauyi, bugu na 3D, da kayan samar da wutar lantarki. Bugu da ƙari, sake yin amfani da kayan aiki na carbon fiber, da shirye-shiryen itace lignin carbon fiber da sauran nasarori suna da kyakkyawan aikin ido. An bayyana sakamakon wakilci a ƙasa:

1) Cibiyar Fasaha ta Jojiya ta Amurka ta karya ta fasahar fiber fiber na ƙarni na uku

A cikin Yuli 2015, tare da DARPA kudade, Georgia Institute of Technology, tare da m pan-tushen carbon fiber gel kadi dabara, muhimmanci ya karu da modules, ya zarce da Hershey IM7 Carbon fiber, wanda yanzu yadu amfani da soja jirgin sama, alama kasa ta biyu a duniya don ƙware na uku ƙarni na carbon fiber fasahar bayan Japan.

Ƙarfin jujjuyawar fiber carbon fiber na gel ɗin da Kumarz ya yi ya kai 5.5 zuwa 5.8Gpa, kuma madaidaicin ma'aunin yana tsakanin 354-375gpa. "Wannan shi ne ci gaba da fiber da aka ruwaito tare da mafi girma ƙarfi da kuma modulus na m aiki. A cikin gajeren filament dam, da tensile ƙarfi har zuwa 12.1Gpa, guda shi ne mafi girma polyacrylonitrile carbon fiber."

2) Fasahar dumama wutar lantarki

A cikin 2014, Nedo ya haɓaka fasahar dumama igiyoyin lantarki. Fasahar carbonization na lantarki tana nufin amfani da fasahar dumama igiyar wutar lantarki zuwa carbonization fiber a matsin yanayi. The samu carbon fiber yi ne m guda da carbon fiber samar da high zafin jiki dumama, na roba modulus iya isa fiye da 240GPA, da elongation a hutu ne fiye da 1.5%, wanda shi ne na farko nasara a duniya.

Abubuwan da ke kama da fiber suna carbonized ta hanyar igiyar lantarki, ta yadda ba a buƙatar kayan wutar lantarki da ake amfani da su don dumama zafin jiki. Wannan tsari ba kawai yana rage lokacin da ake buƙata don carbonization ba, amma kuma yana rage yawan makamashi da kuma rage fitar da CO2.

3) lafiya kula da carbonization tsari

A cikin Maris 2014, Toray ya sanar da nasarar ci gaban t1100g carbon fiber. Toray yana amfani da fasahar jujjuyawar kwanon gargajiya na gargajiya don sarrafa tsarin carbonization, haɓaka microstructure na fiber carbon akan nanoscale, sarrafa yanayin graphite microcrystalline, girman microcrystalline, lahani da sauransu a cikin fiber bayan carbonization, don haɓaka ƙarfi da na roba modules za a iya inganta sosai. Ƙarfin ƙarfi na t1100g shine 6.6GPa, wanda shine 12% mafi girma fiye da na T800, kuma maɗaukaki na roba shine 324GPa kuma ya karu da 10%, wanda ke shiga matakin masana'antu.

4) Fasahar Maganin Sama

Jihar Teijin ta Gabas ta yi nasarar samar da fasahar kula da fuskar plasma da za ta iya sarrafa kamannin fiber carbon cikin 'yan dakiku kadan. Wannan sabuwar fasaha yana sauƙaƙa dukkan tsarin samarwa kuma yana rage yawan amfani da makamashi da kashi 50% idan aka kwatanta da fasahar jiyya da ake da ita don maganin ruwa na lantarki. Bugu da ƙari, bayan maganin plasma, an gano cewa an inganta mannewar fiber da resin matrix.

5) nazari a kan adadin riƙewar carbon fiber tensile ƙarfi a high zafin jiki graphite yanayi

Ningbo kayan samu nasarar za'ayi wani cikakken binciken a kan aiwatar bincike, tsarin bincike da kuma yi ingantawa na gida high ƙarfi da tsayi yanayin carbon fiber, musamman aikin bincike a kan riƙe kudi na carbon fiber tensile ƙarfi a high zafin jiki graphite yanayi, da kuma kwanan nan nasara shiri na high ƙarfi da kuma mafi girma Modules carbon fiber tare da tensile ƙarfi 5.24GPa da tensile modulus girma 593GPa, Ya ci gaba da 6 Japan ƙarfi da ƙarfi idan aka kwatanta da 593GPa. fiber carbon fiber mai ƙarfi mai ƙarfi (ƙarfin ƙarfi 3.92GPa, modulus tensile 588GPa).

6) Microwave Graphite

Yongda Advanced Materials ya samu nasarar ɓullo da Amurka keɓaɓɓen lamban kira matsananci-high zafin jiki graphite fasaha, samar da matsakaici da kuma mafi girma-oda carbon fiber, samu nasarar karya ta cikin uku bottlenecks a cikin ci gaban high-oda carbon fiber, graphite kayan aiki ne tsada da kuma karkashin kasa da kasa iko, raw siliki sinadaran fasaha matsaloli, samar da samar da low da high cost. Ya zuwa yanzu, Yongda ya haɓaka nau'ikan fiber na carbon guda 3, waɗanda dukkansu sun ɗaga ƙarfi da ma'auni na ainihin ƙarancin fiber carbon fiber zuwa wani sabon tsayi.

7) Sabon tsari na narkewar walƙiya na tushen fiber carbon fiber raw waya ta Fraunhofer, Jamus

Cibiyar Fraunhofer ta Polymers (Aikin Bincike na polymer, IAP) kwanan nan ya sanar da cewa zai nuna sabuwar fasahar Comcarbon a Berlin Air Show Ila a Afrilu 2018 25, 29th. Wannan fasaha yana rage yawan farashin samar da fiber carbon fiber da ake samarwa da yawa.

Hoto 4 Raw waya narkakken kadi.

Sanannen abu ne cewa a cikin tsarin al'ada, rabin farashin samar da fiber carbon fiber na tushen kwanon rufi yana cinyewa a cikin aiwatar da samar da danyen waya. Dangane da rashin iya narkar da danyen waya, dole ne a samar da ita ta amfani da tsari mai kadi mai tsada (Solution Spinning). "Don haka, mun kirkiro wani sabon tsari na samar da danyen siliki na kwanon rufi, wanda zai iya rage farashin samar da danyen waya da kashi 60%. Wannan tsari ne na tattalin arziki kuma mai yuwuwa na narkewa, ta yin amfani da na'urar da aka ƙera musamman gauraye na copolymer. "Dr. Johannes Ganster, Ministan Halitta Polymers a Cibiyar Fraunhofer IAP, ya bayyana.

8) Fasaha oxidation na Plasma

4M Carbon Fiber ya sanar da cewa zai yi amfani da fasahar oxidation na plasma don kerawa da siyar da inganci mai inganci, fiber carbon fiber mai rahusa azaman dabarun mayar da hankali, ba kawai don lasisin fasahar ba. 4M ya yi iƙirarin cewa fasahar oxidation na plasma sau 3 cikin sauri fiye da fasahar oxidation na al'ada, yayin da amfani da makamashi bai wuce kashi ɗaya bisa uku na fasahar gargajiya ba. Kuma yawancin masu samar da fiber carbon na ƙasa da ƙasa sun tabbatar da maganganun, waɗanda ke tuntuɓar manyan masana'antun fiber carbon fiber na duniya da masu kera motoci don shiga a matsayin waɗanda suka fara samar da filayen carbon mai rahusa.

9) Cellulose Nano fiber

Jami'ar Kyoto ta Japan, tare da wasu manyan abubuwan da ke samar da kayan aiki irin su kamfanin shigar da wutar lantarki (babban mai ba da kayayyaki na Toyota) da Daikyonishikawa Corp., suna aiki kan samar da kayan filastik da ke hade da cellulose nanofibers, An yi wannan abu ta hanyar karya ɓangaren itacen zuwa ƙananan microns (1 a kowace dubu mm). Nauyin sabon kayan shine kawai kashi ɗaya cikin biyar na nauyin karfe, amma ƙarfinsa ya ninka sau biyar na karfe.

10) carbon fiber gaban jiki na polyolefin da lignin albarkatun kasa

The Oak Ridge National Laboratory a Amurka yana aiki a kan rahusa bincike fiber carbon tun 2007, kuma sun ɓullo da carbon fiber gaban gaban polyolefin da lignin albarkatun kasa, kazalika da ci-gaba plasma pre-oxidation da microwave carbonization fasahar.

11) Sabuwar polymer (polymer precursor) an haɓaka ta ta hanyar cire jiyya mai ƙima

A cikin hanyar masana'antu da Jami'ar Tokyo ke jagoranta, an samar da sabon polymer (polymer precursor) don cire jiyya mara kyau. Babban abin lura shine bayan jujjuya polymer ɗin zuwa siliki, ba ya aiwatar da ainihin maganin hana ruwa, amma yana haifar da oxidize a cikin sauran ƙarfi. Ana dumama na'urar dumama microwave zuwa fiye da 1000 ℃ don carbonization. Lokacin dumama yana ɗaukar mintuna 2-3 kawai. Bayan maganin carbonization, ana kuma amfani da plasma don aiwatar da maganin saman, ta yadda za'a iya yin fiber carbon. Maganin Plasma yana ɗaukar ƙasa da mintuna 2. Ta wannan hanyar, ainihin lokacin ɓacin rai na mintuna 30-60 ana iya rage shi zuwa kusan mintuna 5. A cikin sabuwar hanyar masana'anta, ana aiwatar da maganin plasma don haɓaka haɗin gwiwa tsakanin fiber carbon da resin thermoplastic azaman kayan tushe na CFRP. Module na roba na fiber carbon da aka ƙera ta sabon hanyar masana'anta shine 240GPa, ƙarfin ƙarfi shine 3.5GPa kuma elongation ya kai 1.5%. Waɗannan ƙimar daidai suke da darajar Toray Universal na carbon fiber T300 da ake amfani da su don kayan wasa, da sauransu.

12) sake yin amfani da kayan aikin fiber carbon ta amfani da tsarin gado mai ruwa

Mengran Meng, mawallafin farko na binciken, ya ce: "Mayar da fiber na carbon yana rage tasirin muhalli idan aka kwatanta da samar da fiber na carbon, amma akwai iyakataccen fahimtar yiwuwar fasahar sake amfani da shi da kuma yiwuwar tattalin arziki na sake yin amfani da fiber carbon. "Sake yin amfani da shi yana ɗaukar matakai biyu: dole ne a fara dawo da zaruruwa daga cikin abubuwan da ake amfani da su na carbon fiber composites da thermally bazuwa ta hanyar yin amfani da kayan aikin injiniya na lantarki. Waɗannan hanyoyin suna cire ɓangaren filastik na kayan da aka haɗa, suna barin fiber carbon, wanda za'a iya canza shi zuwa matsugunan fiber ɗin da aka ƙulla ta amfani da fasahar yin takarda mai jika, ko kuma a sake tsara su zuwa filayen kwatance.

Masu binciken sun ƙididdige cewa za a iya dawo da fiber ɗin carbon daga sharar da ke tattare da fiber carbon ta amfani da tsarin gado mai ruwa, yana buƙatar kawai 5 na dala/kg da ƙasa da 10% na makamashin da ake buƙata don kera fiber na farko na carbon. Filayen carbon da aka sake yin amfani da su ta hanyar tsarin gado mai ruwa da ruwa da kyar suna rage ma'ana, kuma ƙarfin ƙarfi yana raguwa da kashi 18% zuwa 50% dangane da filayen carbon na farko, yana sa su dace da aikace-aikacen da ke buƙatar taurin kai maimakon ƙarfi. "Filayen carbon da aka sake yin fa'ida na iya dacewa da aikace-aikacen da ba na tsari ba waɗanda ke buƙatar nauyi, kamar masana'antar kera motoci, gini, iska da masana'antar wasanni," in ji Meng.

13) Sabuwar fasahar sake amfani da fiber carbon da aka haɓaka a Amurka

Yuni 2016, masu bincike a Cibiyar Fasaha ta Jojiya a Amurka sun jika fiber carbon a cikin wani ƙarfi mai ɗauke da barasa don narkar da resin epoxy, za a iya sake amfani da zaruruwan zaruruwa da resin epoxy, nasarar samun nasarar dawo da fiber carbon.

Yuli 2017, Jami'ar Jihar Washington kuma ta haɓaka fasahar dawo da fiber carbon fiber, ta yin amfani da raunin acid a matsayin mai haɓakawa, yin amfani da ethanol na ruwa a ƙananan yanayin zafi don bazuwar kayan zafi, bazuwar fiber carbon da resin ana kiyaye su daban, kuma ana iya saka shi cikin haifuwa.

14) Haɓaka fasahar tawada tawada ta 3D ta carbon fiber a cikin dakin gwaje-gwaje na LLNL, Amurka

A cikin Maris 2017, da Lawrence Livemore National Laboratory (LLNL) a Amurka ya ɓullo da na farko 3D buga high-aiki, jirgin sama-sa carbon fiber composites. Sun yi amfani da hanyar bugu na 3D na watsa tawada kai tsaye (DIW) don ƙirƙirar hadaddun sifofi masu girma uku waɗanda ke haɓaka saurin sarrafawa don amfani da su a cikin motoci, sararin samaniya, tsaro, da gasar babur da hawan igiyar ruwa.

15) Amurka, Koriya da Sin sun hada kai wajen samar da sinadarin Carbon don samar da wutar lantarki

A cikin watan Agusta na 2017, harabar Dallas na Jami'ar Texas, Jami'ar Hanyang ta Koriya, Jami'ar Nankai ta kasar Sin da sauran cibiyoyi sun yi hadin gwiwa wajen samar da kayan zaren carbon fiber don samar da wutar lantarki. An fara jiƙa zaren a cikin mafita na electrolyte kamar brine, yana ba da damar ions da ke cikin electrolyte don haɗawa da saman carbon nanotubes, wanda za'a iya canza shi zuwa makamashin lantarki lokacin da zaren ya ɗaure ko shimfiɗa. Ana iya amfani da kayan a kowane wuri tare da ingantaccen makamashin motsa jiki kuma ya dace da samar da wutar lantarki ga na'urori masu auna firikwensin IoT.

16) Sabon ci gaba a cikin binciken itace lignin carbon fiber da Sin da Amurka suka samu

A watan Maris 2017, da musamman fiber tawagar Ningbo Institute of Materials Technology da aikin injiniya shirya lignin-acrylonitrile copolymer tare da mai kyau spinnability da thermal kwanciyar hankali ta amfani da esterification da free m copolymerization biyu-mataki gyare-gyare fasaha. An sami babban ingancin ci gaba da filament ta hanyar amfani da tsarin copolymer da rigar kadi, kuma an karɓi ƙarancin fiber carbon bayan daidaitawar thermal da maganin carbonization.

A cikin watan Agustan 2017, ƙungiyar binciken Birgitte ahring a Jami'ar Washington ta Amurka ta haɗu da lignin da polyacrylonitrile daban-daban, sannan suka yi amfani da fasahar narke kaɗa don canza gaurayen polymers zuwa carbon fibers. Binciken ya gano cewa lignin da aka ƙara zuwa kashi 20% ~ 30% bai shafi ƙarfin carbon fiber ba kuma ana sa ran za a yi amfani da shi wajen kera kayan fiber na carbon mai rahusa don sassa na motoci ko jirgin sama.

A karshen shekarar 2017, Cibiyar Nazarin Makamashi ta Kasa (NREL) ta fitar da bincike kan kera sinadarin acrylonitrile ta hanyar amfani da sharar sassan tsirrai, kamar bambaro na masara da bambaro na alkama. Da farko su kan karya kayan shuka su zama sikari sannan su mayar da su acid, sannan su hada su da masu kara kuzari don samar da kayayyakin da ake bukata.

17) Japan ta haɓaka ƙaƙƙarfan fiber carbon na farko da aka ƙarfafa thermoplastic composite chassis mota

Oktoba 2017, Japan ta sabon makamashi masana'antu fasahar hadedde R & amp; d Agency da Jami'ar Nagoya National Composites Research Centre sun sami nasarar haɓaka filayen carbon fiber na farko a duniya wanda ke ƙarfafa chassis ɗin mota mai haɗaɗɗiyar thermoplastic. Suna amfani da atomatik dogon fiber ƙarfafa thermoplastic composites kai tsaye kan-line gyare-gyaren tsari, ci gaba da carbon fiber da thermoplastic guduro barbashi hadawa, masana'antu fiber ƙarfafa composites, sa'an nan ta hanyar dumama da narkewa dangane, nasarar samar da thermoplastic CFRP mota chassis.

5. shawarwari akan R & D na fasahar fiber carbon a China

5.1 Tsarin gaba-gaba, mai manufa, mai da hankali kan keta fasahar fiber carbon na ƙarni na uku.

Fasahar fiber carbon fiber na ƙarni na biyu na kasar Sin ba ta zama cikakkiyar nasara ba tukuna, ya kamata kasarmu ta yi ƙoƙari ta kasance kyakkyawan tsari wanda zai kawo haɗin kan cibiyoyin bincike masu dacewa, da mai da hankali kan kama manyan fasahohi, da mayar da hankali ga ƙarni na uku na babban aikin bincike da haɓaka fasahar carbon fiber shirye-shiryen fasaha (watau ya dace da ƙarfin sararin samaniya, babban ƙarfin gyaran sararin samaniya, babban gyaran gyare-gyaren carbon fiber da fasaha na fasaha mai ƙarfi, da fasahar kere kere na carbon fiber, da sauran fasahar fiber carbon fiber, gami da fasahar kere kere na carbon fiber, da sauran fasahar fiber carbon fiber, gami da fasahar fiber carbon da sauran abubuwan gina jiki, gami da fasaha na carbon fiber). arha mai girma babban ja na carbon fiber shiri, ƙari masana'antu fasahar carbon fiber hada kayan, sake amfani da fasaha da kuma m samfur fasahar.

5.2 Ƙungiyar haɗin gwiwa, ƙarfafa goyon baya, kafa manyan ayyukan fasaha don ci gaba da tallafawa bincike na haɗin gwiwa

A halin yanzu, akwai cibiyoyi da yawa don gudanar da bincike na fiber carbon a kasar Sin, amma ikon yana tarwatse, kuma babu R & amp; d tsarin tsari da tallafi mai karfi na kudade don daidaitawa mai inganci. Bisa la'akari da kwarewar ci gaban kasashe masu tasowa, tsarawa da tsara manyan ayyuka suna taka muhimmiyar rawa wajen bunkasa wannan fanni na fasaha. Ya kamata mu mayar da hankali a kan kasar Sin Advantage R & amp; d Force, a cikin ra'ayi na kasar Sin ta carbon fiber nasara R & amp; d fasahar da za ta fara manyan ayyuka, da karfafa sabbin fasahohi na hadin gwiwa, da ci gaba da sa kaimi ga matakin fasahar binciken fiber carbon na kasar Sin, da gasa kan fiber carbon fiber na kasa da kasa da hada abubuwa.

5.3 Inganta tsarin kimantawa na aikace-aikacen tasirin tasirin nasarorin fasaha

Daga ma'anar nazarin tattalin arziki na takardun SCI, fiber carbon fiber na kasar Sin a matsayin kayan aiki mai ƙarfi da ake amfani da su a fannoni daban-daban na bincike, amma don samar da fiber carbon da fasahar shirye-shirye, musamman mai da hankali kan rage farashi, inganta haɓakar samar da ƙarancin bincike. Carbon fiber samar tsari ne mai tsawo, fasaha key maki, high samar shinge, shi ne Multi- horo, Multi-technology hadewa, bukatar karya ta hanyar fasaha cikas, don yadda ya kamata inganta da "low cost, high yi" core shirye-shirye fasahar bincike da kuma ci gaba, a daya hannun, bukatar don ƙarfafa bincike zuba jari, a daya hannun, bukatar don raunana filin na kimiyya bincike aikin kimantawa da fasaha sakamako, ƙarfafa sakamakon kima daga fasaha da fasaha. kimantawa na "ƙididdigewa", wanda ke ba da hankali ga buga takarda, zuwa ƙimar "inganci" na ƙimar sakamakon.

5.4 Ƙarfafa noman fasaha na fasaha na fasaha

A high-tech sifa na carbon fiber fasahar kayyade muhimmancin na musamman basira, ko suna da yankan-baki core fasaha ma'aikata kai tsaye kayyade matakin R & amp; D na wata cibiya.

A sakamakon fasahar fiber fiber carbon R & D links, ya kamata mu kula da horo na fili ma'aikata, domin tabbatar da daidaituwa da kuma ci gaban duk links. Bugu da kari, daga tarihin ci gaban bincike na fiber carbon a cikin kasar Sin, kwararar kwararrun kwararrun fasahar galibi galibi muhimmin abu ne da ke shafar R & amp; d matakin cibiyar bincike. Kula da kayyade na core masana da R & amp; d ƙungiyoyi a cikin ayyukan samarwa, masu haɗaka da manyan samfuran suna da mahimmanci don haɓaka fasahar ci gaba.

Ya kamata mu ci gaba da ƙarfafa horarwa da amfani da ƙwararrun ma'aikatan fasaha a wannan fanni, inganta kimantawa da manufofin kulawa don Fasaha R & amp; d basira, ƙarfafa namo na matasa iyawa, rayayye goyon bayan hadin gwiwa da musayar tare da kasashen waje ci-gaba R & amp; d cibiyoyi, da ƙwazo wajen gabatar da ƙwararrun ƙwararrun ƙwararrun ƙasashen waje, da dai sauransu. Wannan zai taka muhimmiyar rawa wajen haɓaka aikin binciken fiber carbon a kasar Sin.

An ruwaito daga-

Binciken ci gaban fasahar fiber carbon fiber na duniya da wayewarta ga kasar Sin. Tian Yajuan,Zhang Zhiqiang,Tao Cheng,Yang ming,Ba jin,Chen Yunwei.Duniya Sci-Tech R & D.2018

Lokacin aikawa: Dec-04-2018