A cewar sabon rahoto, ƙarni na gaba na kayan haɗin gwiwar za su iya lura da yanayin lafiyar tsarin su, kuma su zama gama gari.

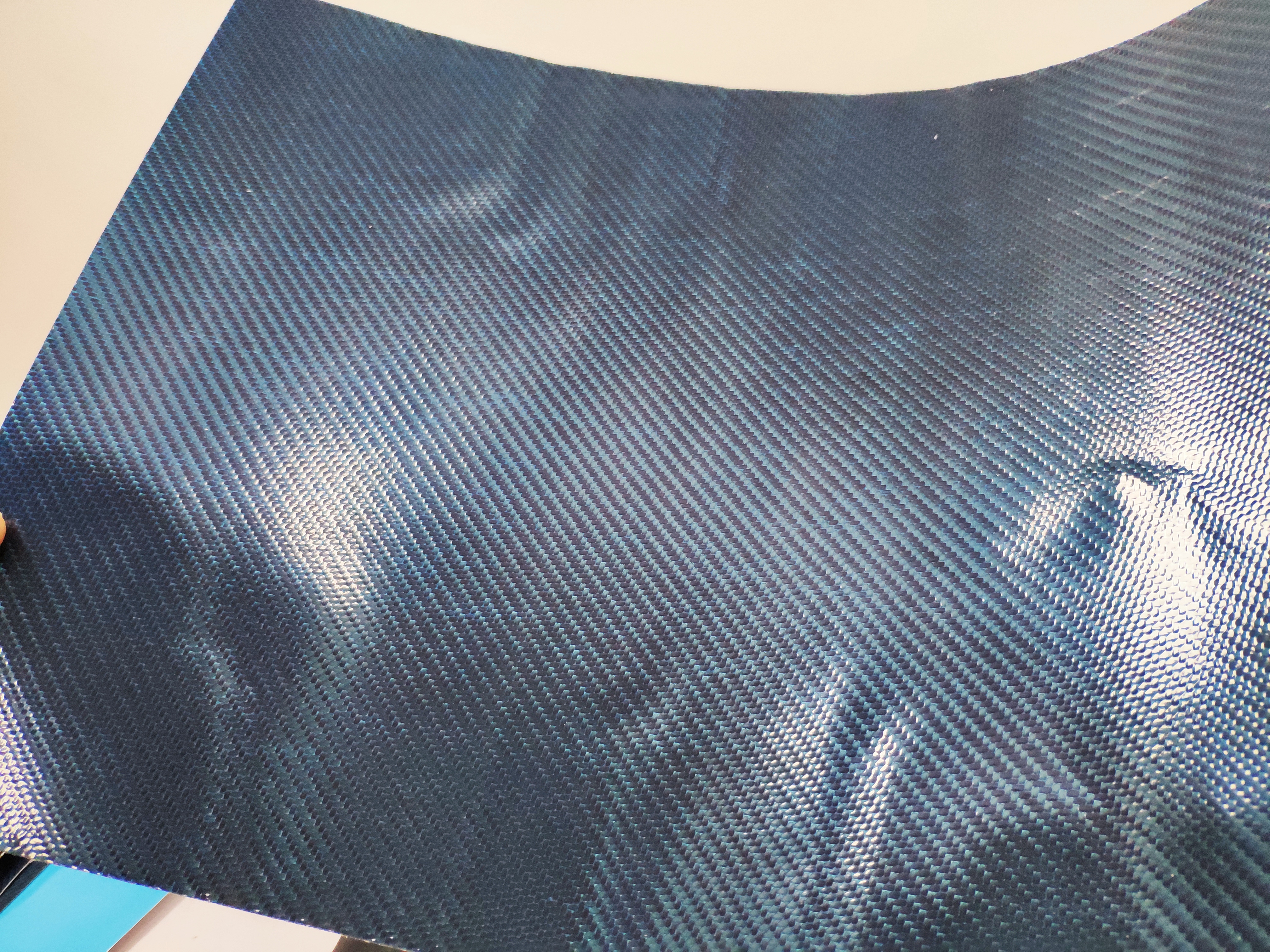

Haɗin fiber carbon suna da haske da ƙarfi kuma sune mahimman kayan gini don motoci, jiragen sama da sauran hanyoyin sufuri. Sun ƙunshi nau'ikan nau'ikan polymer, irin su resin epoxy, waɗanda aka haɗa tare da filayen carbon da aka ƙarfafa. Saboda nau'ikan kayan aikin injiniya daban-daban na kayan biyu, zaruruwa za su faɗo daga ƙasa ƙarƙashin matsanancin damuwa ko gajiya. Wannan yana nufin cewa lalacewar tsarin haɗin fiber carbon zai iya kasancewa a ɓoye a ƙasa da ƙasa kuma ido tsirara ba zai iya gano shi ba, wanda zai haifar da gazawar bala'i.

"Ta hanyar fahimtar abubuwan da ke cikin abubuwan da aka haɗa, za ku iya yin hukunci da lafiyarsu da kyau kuma ku san idan akwai wata lalacewa da ke buƙatar gyara," Ridge Chris Bowland, wani mai bincike a cikin binciken.

Laboratory National Oak Ridge a Ma'aikatar Makamashi ta Amurka (Labaran Oak na Kasa) Wigner. "Kwanan nan, Amit Naskar, shugaban ƙungiyar carbon da composites a Bowland da ORNL, ya ƙirƙira hanyar birgima don nannade zaruruwan carbon da ke kan siliki carbide nanoparticles na nanomaterials an haɗa su a cikin kayan haɗin gwiwar da suka fi ƙarfi fiye da sauran abubuwan haɗin fiber da aka ƙarfafa su kuma suna da isasshen ingantaccen tsarin nasu. a cikin polymer, da zaruruwa samar da wani iko grid, da kuma girma composites gudanar da wutar lantarki Semiconductor nanoparticles iya halakar da wannan lantarki watsin karkashin aikin na waje sojojin, ƙara inji da lantarki ayyuka zuwa composites. reshe yana ƙarƙashin matsin lamba da yawa kuma yana ba da shawarar gwajin gwaji na mirgina na ORNL yana tabbatar da ka'ida cewa hanyar zata iya samar da ƙarni na gaba na filaye masu rufi a kan babban ma'auni.Magungunan jin daɗin kai, wataƙila an yi su ne daga abubuwan da za a iya sabunta su na polymer da ƙananan ƙwayoyin carbon, na iya samun wurinsu a cikin samfuran da aka sanya, ciki har da 3D bugu da aka buga a cikin gine-gine Fiber ɗin carbon mai girma yana zubewa a kan rollers, kuma rollers ɗin sun jiƙa zarurukan a cikin resin epoxy, waɗanda ke ɗauke da nanoparticles da ake samu a kasuwa, wanda faɗinsa kusan faɗin ƙwayar cuta ne (45-65 nm).

Ana bushe zarurukan a cikin tanda don tabbatar da rufin. Don gwada ƙarfin fibers ɗin da aka saka a cikin nanoparticles ɗin da aka manne ga ma'aunin polymer, masu binciken sun yi ƙwanƙwasa ƙwanƙwasa fiber mai ƙarfi, waɗanda aka shirya su a cikin Hanya ɗaya. Bowland ta gudanar da gwajin damuwa wanda ƙarshen cantilever ya daidaita, yayin da injin da ke kimanta kayan aikin injin da aka yi amfani da shi a tsakiyar katako ya gaza. Domin yin nazarin iya fahimtar abubuwan da aka haɗa, ya sanya na'urorin lantarki a bangarorin biyu na katako na cantilever. A cikin na'ura da aka sani da "Dynamic mechanical analyzer," ya yanke gefe ɗaya don kiyaye cantilever a tsaye. Injin yana yin ƙarfi a ɗayan ƙarshen don lanƙwasa katakon dakatarwa yayin da Bowland ke sa ido kan canjin juriya. ORNL, mai bincike na postdoctoral Ngoc Nguyen, ya gudanar da ƙarin gwaje-gwaje a cikin Fourier Transform Infrared spectrometer don nazarin haɗin sinadarai a cikin abubuwan da aka haɗa da haɓaka fahimtar ingantaccen ƙarfin injin da aka gani. Har ila yau, masu binciken sun gwada iyawar makamashin da aka yi amfani da su na abubuwan da aka yi da nau'o'in nanoparticles (wanda aka auna ta hanyar halayen damping), wanda zai sauƙaƙe mayar da martani na kayan tsarin zuwa girgiza, girgizawa da sauran matsalolin damuwa da damuwa. A kowane maida hankali, nanoparticles na iya haɓaka ɓarnawar makamashi (daga 65% zuwa 257% zuwa digiri daban-daban). Bowland da Naskar sun nemi takardar izinin tsari don kera abubuwan haɗin fiber carbon fiber mai ji da kai.

Ana bushe zarurukan a cikin tanda don tabbatar da rufin. Don gwada ƙarfin fibers ɗin da aka saka a cikin nanoparticles ɗin da aka manne ga ma'aunin polymer, masu binciken sun yi ƙwanƙwasa ƙwanƙwasa fiber mai ƙarfi, waɗanda aka shirya su a cikin Hanya ɗaya. Bowland ta gudanar da gwajin damuwa wanda ƙarshen cantilever ya daidaita, yayin da injin da ke kimanta kayan aikin injin da aka yi amfani da shi a tsakiyar katako ya gaza. Domin yin nazarin iya fahimtar abubuwan da aka haɗa, ya sanya na'urorin lantarki a bangarorin biyu na katako na cantilever. A cikin na'ura da aka sani da "Dynamic mechanical analyzer," ya yanke gefe ɗaya don kiyaye cantilever a tsaye. Injin yana yin ƙarfi a ɗayan ƙarshen don lanƙwasa katakon dakatarwa yayin da Bowland ke sa ido kan canjin juriya. ORNL, mai bincike na postdoctoral Ngoc Nguyen, ya gudanar da ƙarin gwaje-gwaje a cikin Fourier Transform Infrared spectrometer don nazarin haɗin sinadarai a cikin abubuwan da aka haɗa da haɓaka fahimtar ingantaccen ƙarfin injin da aka gani. Har ila yau, masu binciken sun gwada iyawar makamashin da aka yi amfani da su na abubuwan da aka yi da nau'o'in nanoparticles (wanda aka auna ta hanyar halayen damping), wanda zai sauƙaƙe mayar da martani na kayan tsarin zuwa girgiza, girgizawa da sauran matsalolin damuwa da damuwa. A kowane maida hankali, nanoparticles na iya haɓaka ɓarnawar makamashi (daga 65% zuwa 257% zuwa digiri daban-daban). Bowland da Naskar sun nemi takardar izinin tsari don kera abubuwan haɗin fiber carbon fiber mai ji da kai.

"Tsarin da aka yi wa ciki ya ba da sabuwar hanya don cin gajiyar sababbin nanomaterials da ake haɓakawa." Bowland ya ce. Binciken ya sami goyan bayan bincike da ayyukan ci gaba wanda Cibiyar Nazarin ORNL ta jagoranta, wanda aka buga a cikin mujallar ACS Applied Materials and Interfaces (Aikace-aikacen Kayan aiki & Interfaces) na American Chemical Society.

Lokacin aikawa: Dec-07-2018