Los ntawm pwm tsim rau demoulding molding, qhov zoo ntawmcov khoom siv carbon fibertej zaum yuav cuam tshuam los ntawm txhua kauj ruam hauv cov txheej txheem molding, xws li pwm tsim, resin cov ntsiab lus piv, tswj qhov kub thiab txias, siv tus neeg tso tawm.

Carbon fiber molding yog ib qho tseem ceeb ntawm cov txheej txheem ntawm cov khoom siv carbon fiber ntau, thiab molding kub hauv cov txheej txheem no yog qhov tseem ceeb cuam tshuam rau qhov zoo ntawm cov khoom siv fiber ntau. Yog li, peb yuav tham txog eQhov cuam tshuam ntawm qhov kub thiab txias ntawm cov khoom molded:

1.Thaum qhov kub thiab txias, qhov curing ceev yuav nrawm dua, uas yuav ua rau o ntawm cov khoom siv fiber ntau, tawg thiab warping deformation.

2.Ntawm qhov tsis sib xws, thaum lub molding kub tsawg dhau lawm, nws yuav ua rau cov khoom tsis zoo fluidity, qeeb curing ceev, thiab cov khoom siv uas tsis muaj tiav.

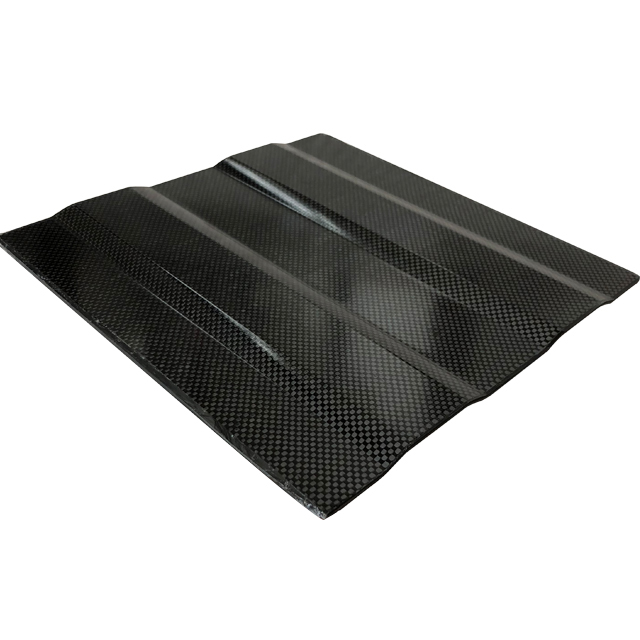

Cov khoom uas muaj cov duab zoo, nyias phab ntsa thickness tsis haum rau siab kub molding.Nws kuj yuav tsum tau cov tsub zuj zuj ntawm ntau yam kev ua tau zoo.

Dongguan Composite Materials Co., Ltd. tshwj xeeb hauv cov khoom siv roj carbon fiber ntau ua thiab muag cov kev pabcuam sib xyaw ua ke, peb tuaj yeem tsim ntau yam kev xav tau, cov qauv siab, cov khoom siv raws li peb cov neeg siv khoom xav tau.

Post lub sij hawm: Jul-15-2018